Antichlor and preparation method thereof

A dechlorination agent and aliphatic amine technology, used in the refining of hydrocarbon oil, petroleum industry, etc., can solve the problems of high viscosity and cannot realize operation, and achieve the effects of superior solubility, good dispersion and significant economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

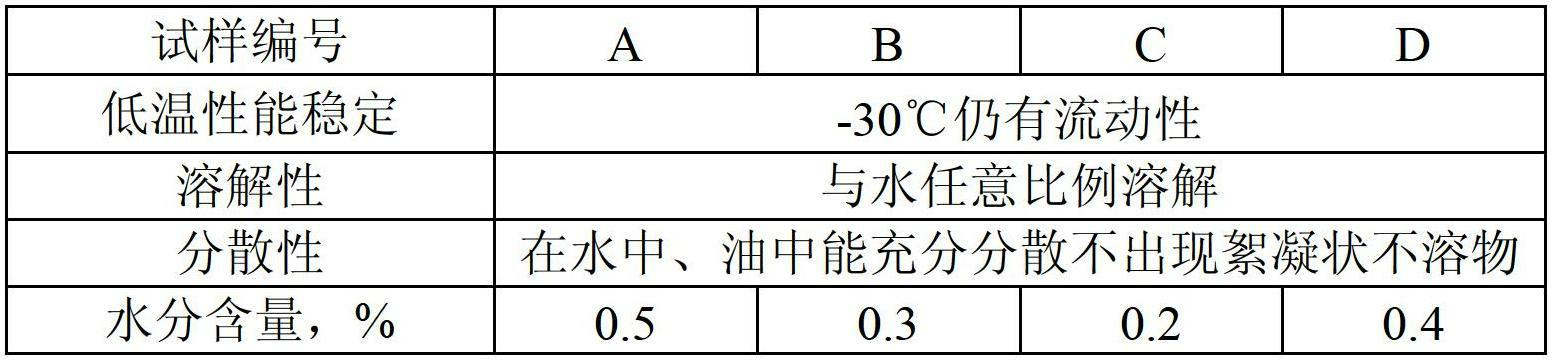

Examples

Embodiment 1

[0021] First add 100g of monoethanolamine into a three-necked flask, then add 200g of diisopropylamine and 200g of morpholine, stir at room temperature and pressure for 30 minutes, and filter to remove impurities to obtain dechlorination agent A.

Embodiment 2

[0023] First add 100g of diethanolamine into a three-necked flask, then add 200g of diisopropylamine, 100g of morpholine and 200g of piperazine, stir at room temperature and pressure for 30 minutes, and filter to remove impurities to obtain dechlorination agent B.

Embodiment 3

[0025] First add 100g of triethanolamine into a three-necked flask, then add 200g of 1,2-propylenediamine and 200g of cyclohexylamine, stir at room temperature and pressure for 30 minutes, and filter to remove impurities to obtain dechlorination agent C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com