Wrinkle type apodization waveguide Bragg grating filter and manufacturing method thereof

A technology of waveguide Bragg and grating filter, which is applied in the direction of optical waveguide lightguide, coupling of optical waveguide, cladding optical fiber, etc., can solve the problems of affecting communication quality, failing to meet the requirements of high reflectivity, and difficult to realize the process, etc., to achieve Improve the side mode suppression ratio, high side mode suppression ratio, and reduce the effect of influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

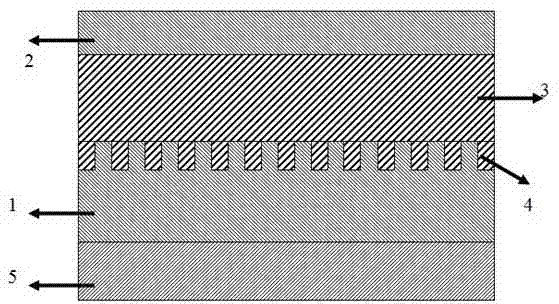

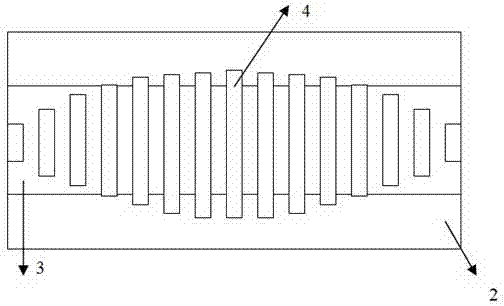

[0029] like figure 1 and figure 2 As shown, a wrinkled apodized waveguide Bragg grating filter of the present invention includes a substrate 5, a lower cladding layer 1, an upper cladding layer 2, a straight waveguide 3 and a lower grating 4 composed of grating lines. The total length of the waveguide grating composed of the straight waveguide 3 and the lower grating 4 is generally on the order of millimeters or centimeters, and the period of the grating in the lower grating 4 is generally several hundred nanometers. The lower cladding layer 1 is fixedly connected to the upper surface of the substrate 5, the lower grating 4 is fixedly connected to the surface of the straight waveguide 3, the bottom surface of the straight waveguide 3 is connected to the top surface of the lower cladding layer 1, and the top surface of the straight waveguid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com