Method for manufacturing flexible touch screen and equipment for manufacturing touch electrode coil

A technology of flexible touch screens and electrode wires, applied in electrical digital data processing, input/output process of data processing, instruments, etc., can solve problems such as low yield rate, bulky and expensive optical control touch screen, and low yield rate of panel manufacturing, and achieve The effect of overcoming the bottleneck of processing size, broad touch application space, and simplifying processing procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

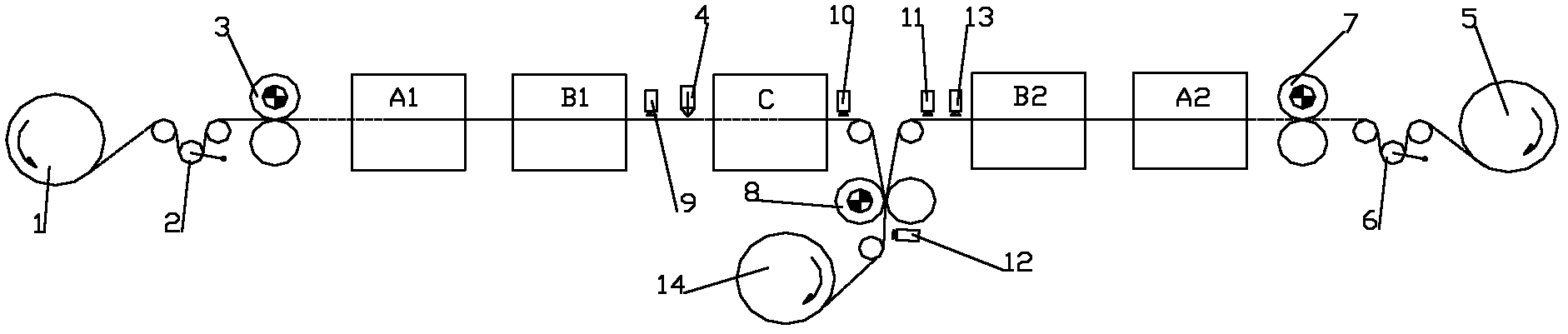

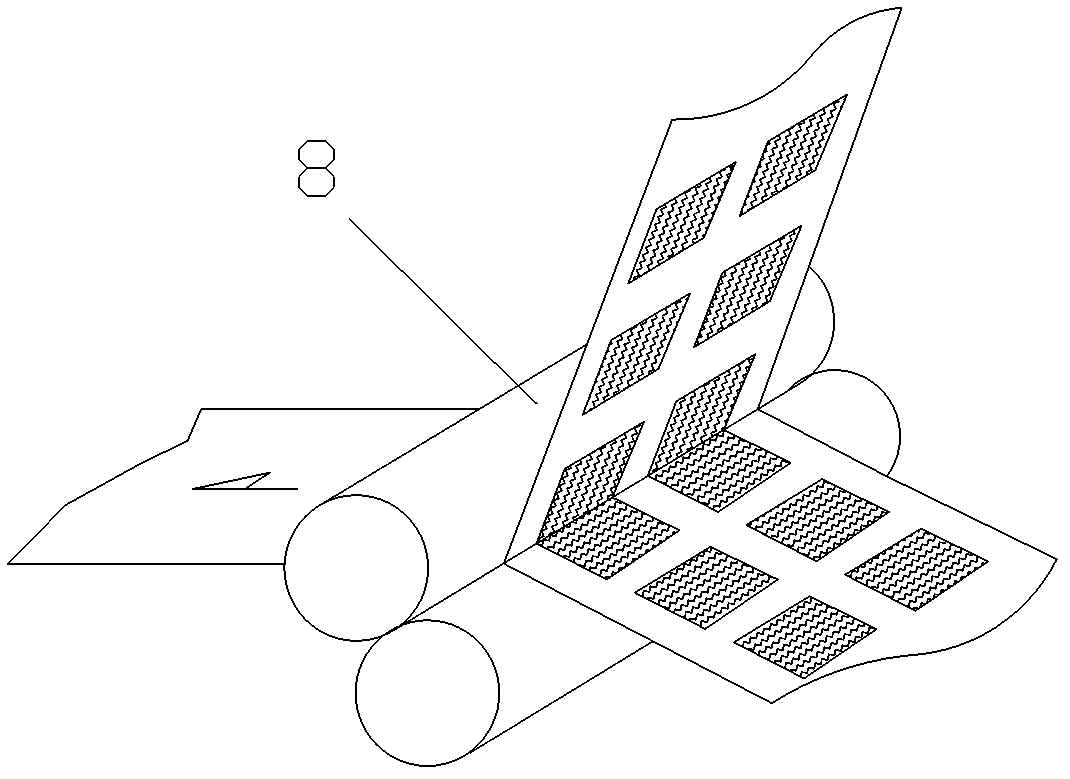

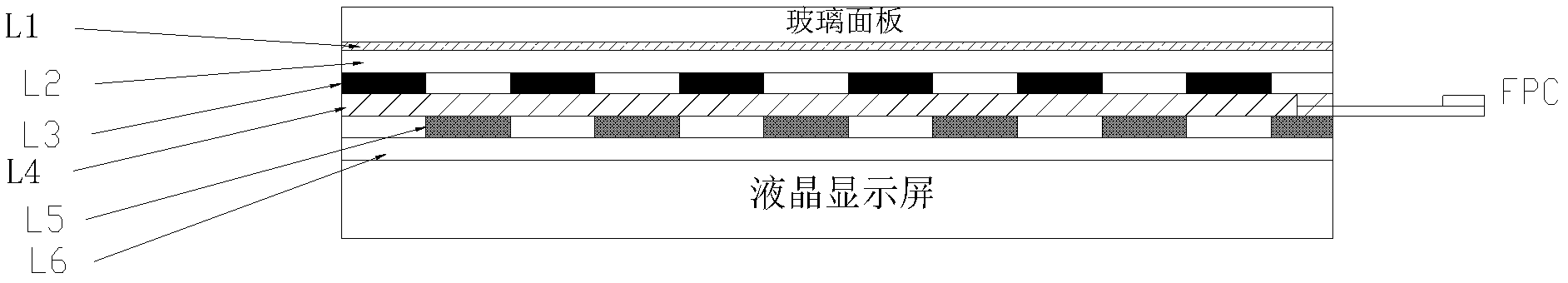

[0050] Such as figure 1 with 2 As shown, the transparent and insulating plastic substrate roll adopts PET (polyethylene terephthalate) roll film with high transmittance and low haze, and the first PET roll film passes through the unwinding machine 1. Tension control Equipment 2, corona equipment (not shown in the figure) and traction device 3, the carbon nanotube ink that is dispersed in advance is printed by predetermined pattern by printing unit A1 (can adopt inkjet printing, gravure printing, flexo printing, nano imprinting Printing method) on the surface of PET, printing positioning marks at the same time, and then drying in an oven to form the first transparent conductive electrode pattern; then synchronously online through the printing unit B1 to transfer the conductive silver paste or copper nano paste to the photoelectric eye or CCD image sensor 9 Tracking and positioning marks are overprinted (inkjet printing, gravure printing, silk screen printing, nanoimprinting) a...

Embodiment 2

[0060] Such as Figure 4 As shown, the transparent and insulating plastic substrate roll adopts a PET (polyethylene terephthalate) roll film with high transmittance and low haze, and the PET roll film passes through an unwinding machine 101 and a tension control device 102 , corona equipment (not shown in the figure) and traction device 103, the carbon nanotube ink that is dispersed in advance is printed respectively by predetermined pattern by printing unit E1 (can adopt roll-to-roll inkjet printing, gravure printing, flexo printing, nano Printing methods such as embossing) on the front of PET, printing positioning marks at the same time, and then drying in an oven to form the first transparent conductive electrode pattern; then synchronously online through the printing unit F1 to print conductive silver paste or copper nano paste by photoelectric eye or The CCD image sensor 109 tracks the positioning marks and overprints (roll-to-roll inkjet printing, gravure printing, rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com