Zipper component and slide zipper, and method for producing zipper component

A manufacturing method and component technology, applied to sliding fastener components, fasteners, clothing, etc., can solve problems such as corrosion, cracks, cracks, large deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0120] Hereinafter, specific examples are given to illustrate the present invention in more detail.

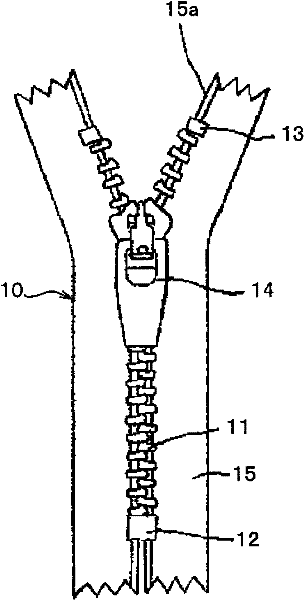

[0121] As Example 1, about manufacturing as a zipper component Figure 3 ~ Figure 5 The case of bottom stop 12 as shown will be described. The bottom stopper 12 of the first embodiment has a component main body made of pure copper and a metal plating film arranged on the surface of the component main body. In this case, the metal plating film is composed of an alloy of copper and zinc in which the copper content is 65 wt % and the zinc content is 35 wt %.

[0122] To manufacture the bottom stopper 12 of the first embodiment, first, a long pure copper wire having a circular cross section is cold-rolled so that the cross section of the pure copper wire is deformed into a substantially H-shape. Next, the component main body of the bottom stopper 12 is produced by cutting the pure copper wire having an H-shaped cross section to a desired thickness in its longitudinal direction. ...

Embodiment 2

[0132] As Example 2, the case where the metal fastener element 11 is manufactured as a slide fastener component is demonstrated.

[0133] The metal fastener element 11 of this Example 2 has the component main body part which consists of the alloy (brass) of copper and zinc, and the metal plating film arrange|positioned on the surface of the component main body part. In this case, the alloy constituting the component main body contains 85 wt% of copper and 15 wt% of zinc. In addition, the metal plating film is composed of an alloy of copper and tin having a copper content of 70 wt % and a tin content of 30 wt %.

[0134] In order to manufacture the metal fastener element 11 of the present Example 2, the engaging head etc. are formed by press-forming a brass plate material having a predetermined thickness, and the plate material is punched to produce the metal fastener element 11 parts of the main body. Thereafter, the obtained component main body was subjected to barrel grind...

Embodiment 3

[0138] As Example 3, the case where an outlet is manufactured as a slide fastener component is demonstrated.

[0139] The socket of the third embodiment has: a component main body using a zinc-based alloy as a metal base material; and a metal plating film arranged on the surface of the component main body. In this case, the component main body includes: a metal body made of a zinc-based alloy; and a copper base plating film formed on the surface of the metal body. In addition, the metal plating film is composed of an alloy of copper and zinc in which the copper content is 65 wt % and the zinc content is 35 wt %.

[0140] In order to manufacture the socket of the third embodiment, first, a metal body for the socket having a predetermined shape is formed by die-casting zinc. Next, the obtained metal body is subjected to electrolytic plating under predetermined conditions to form a copper base plating film on the surface of the metal body, thereby fabricating the component main ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com