Apparatus for manufacturing silicon ingots

A technology for preparing equipment and silicon ingots, which is applied in the direction of directional solidification of eutectic materials, crystal growth, photovoltaic power generation, etc., and can solve the problems of high production costs of silicon ingots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Hereinafter, the present invention will be described in detail by referring to preferred embodiments described with reference to the accompanying drawings so that those of ordinary skill in the art to which the present invention pertains can easily understand and implement.

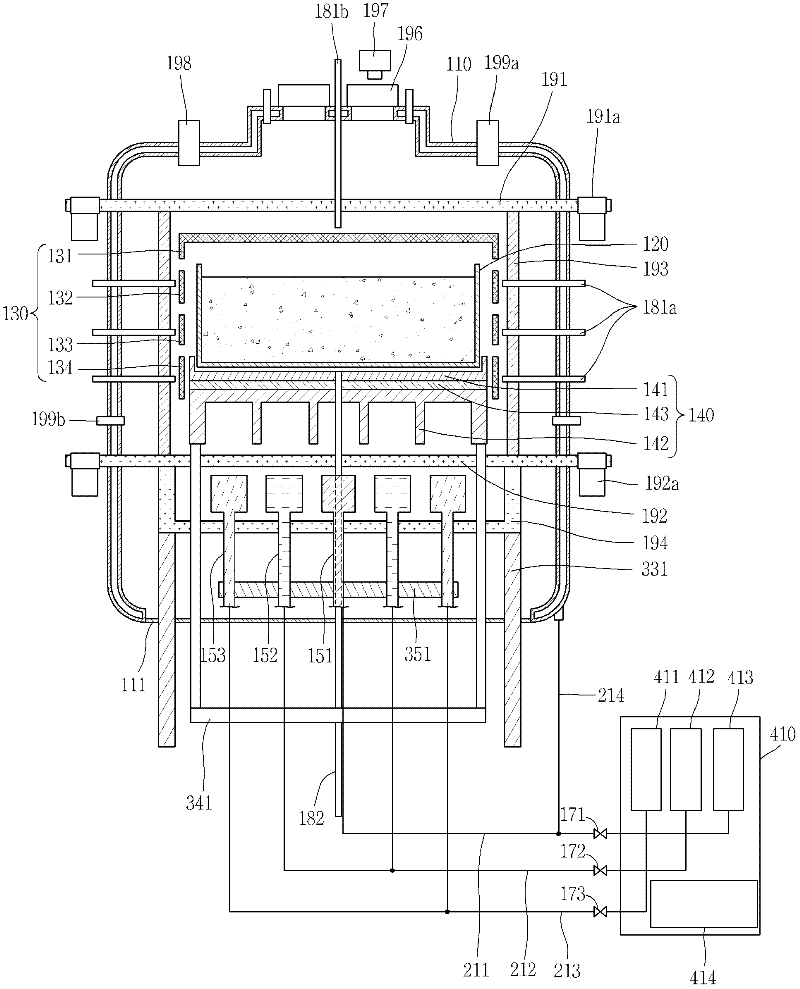

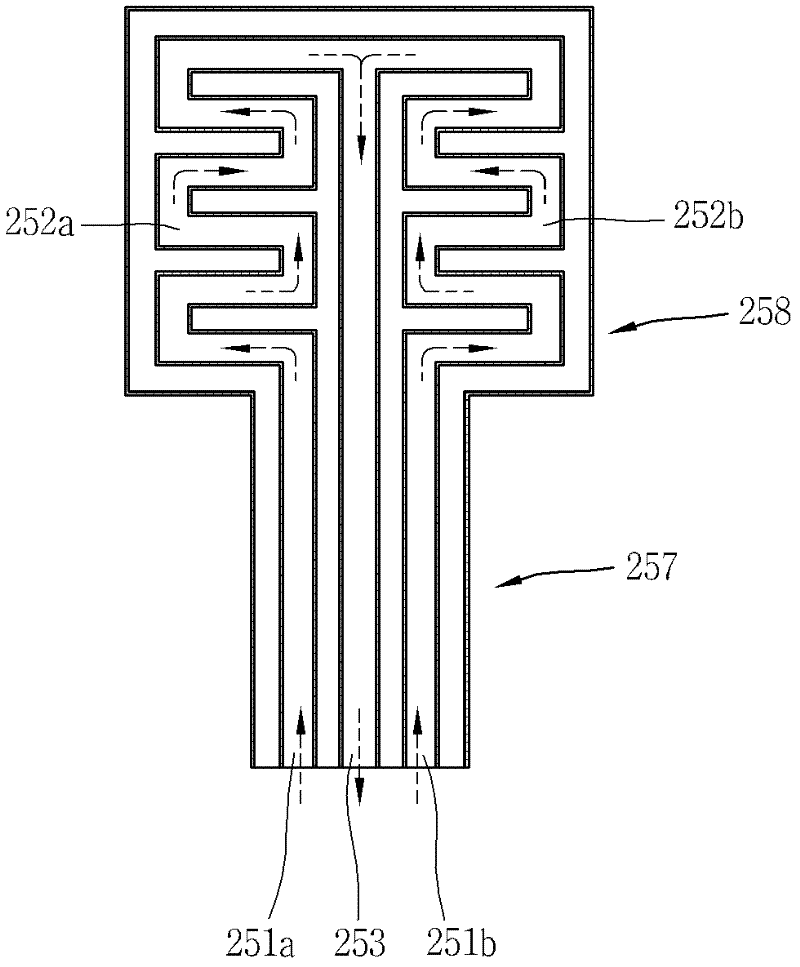

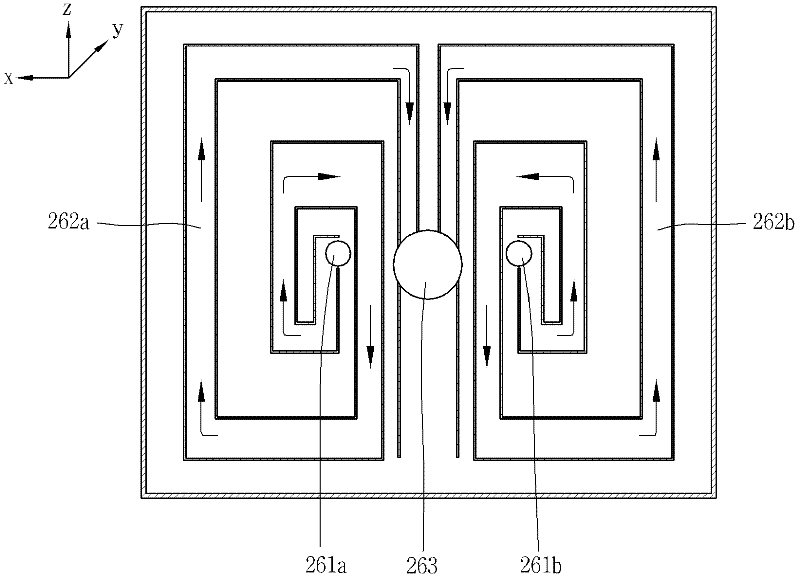

[0031] figure 1 is a schematic structural diagram of a silicon ingot manufacturing device for explaining an embodiment of the present invention, figure 2 and image 3 It is an embodiment of a cross-sectional view of a water-cooled rod representing a silicon ingot preparation device of the present invention, Figure 4 This is an example for explaining the structure in which a plurality of water-cooled rods 130 are connected in the silicon ingot manufacturing apparatus of the present invention.

[0032] First, refer to figure 1 To illustrate, as shown in the figure, the silicon ingot manufacturing device of this embodiment generally includes a chamber 110 , a crucible 120 , a heating unit 130 , a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com