Woven or knitted fabric

A technology of woven fabrics and fibers, applied in warp knitting, weft knitting, textiles and papermaking, etc., to ensure formability and suppress fraying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

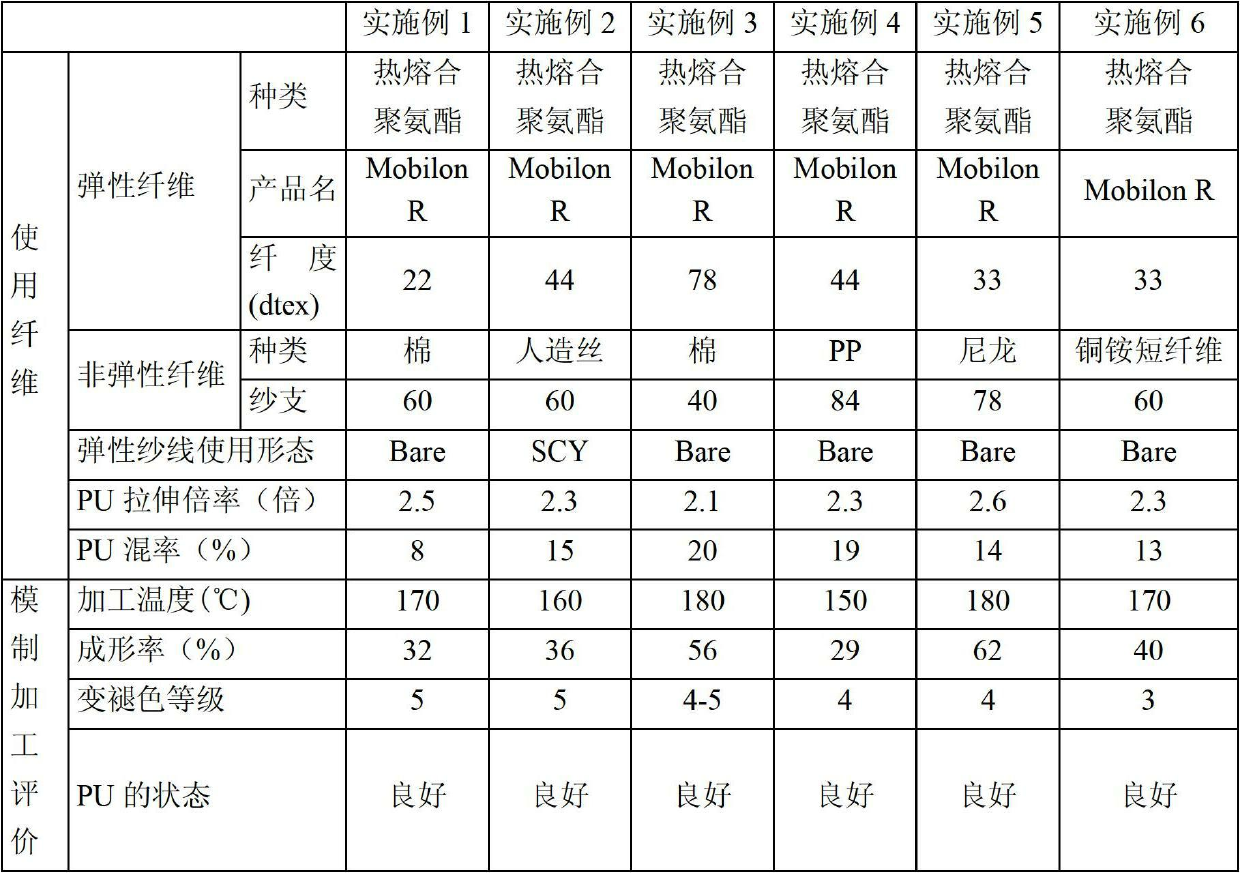

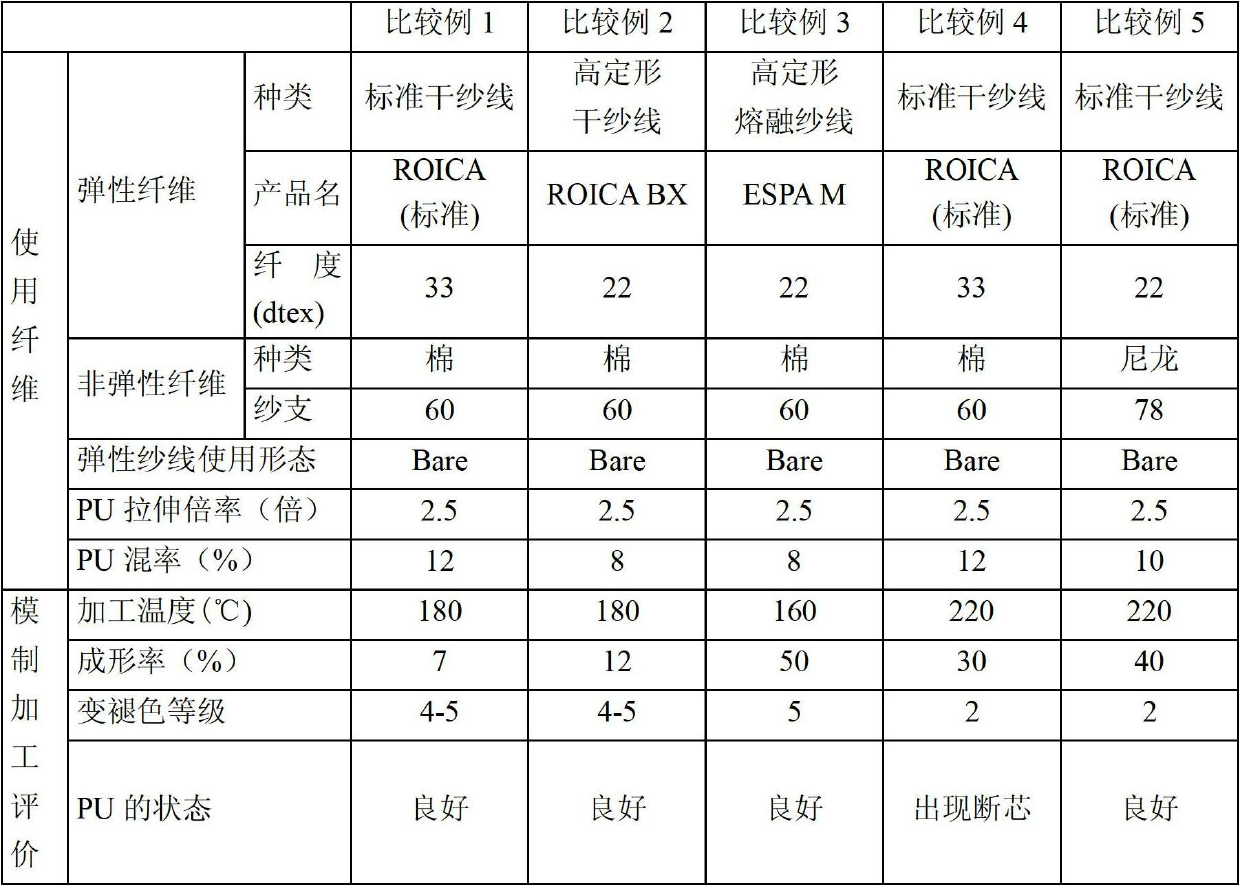

[0060] Cotton 60 / 1 was used as the veil, and MobilonR (22dtex: bare yarn) was used as the heat-fused polyurethane elastic fiber, and a circular knitting machine (28 gauge) was used to plate and knit to produce a jersey. This jersey fabric is subjected to dyeing processing in a normal process, and then to molding processing. Table 1 shows the details of the fibers used and the evaluation results of the molding process.

[0061] In the table, Mobilon R is a registered trademark of Nisshinbo Textile Co., Ltd., ROICA is a registered trademark of Asahi Kasei Fiber Co., Ltd., and ESPA is a registered trademark of Toyobo Co., Ltd. In addition, Bare means bare polyurethane elastic fiber, SCY means single covered yarn, PP means polypropylene, and PU means polyurethane elastic fiber.

Embodiment 2~6

[0063] Using the fibers shown in Table 1, processing was carried out in the same manner as in Example 1. In addition, the structure of the heat fusion polyurethane elastic fiber (SCY) used in Example 2 is as follows.

[0064] Core: heat-fused polyurethane elastane (Mobilon R), sheath: nylon (13dtex)

[0065] Draw ratio: 2.3 times, twist number: 600T / m

[0066] When making blanks, SCY weaves at equal magnification

[0067] Table 1 shows the details of the fibers used and the evaluation results of the molding process. In addition, Examples 2 to 6 are examples in which the fineness of the thermally fused polyurethane elastic fibers and / or the type of non-elastic fibers used in combination were changed and implemented.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com