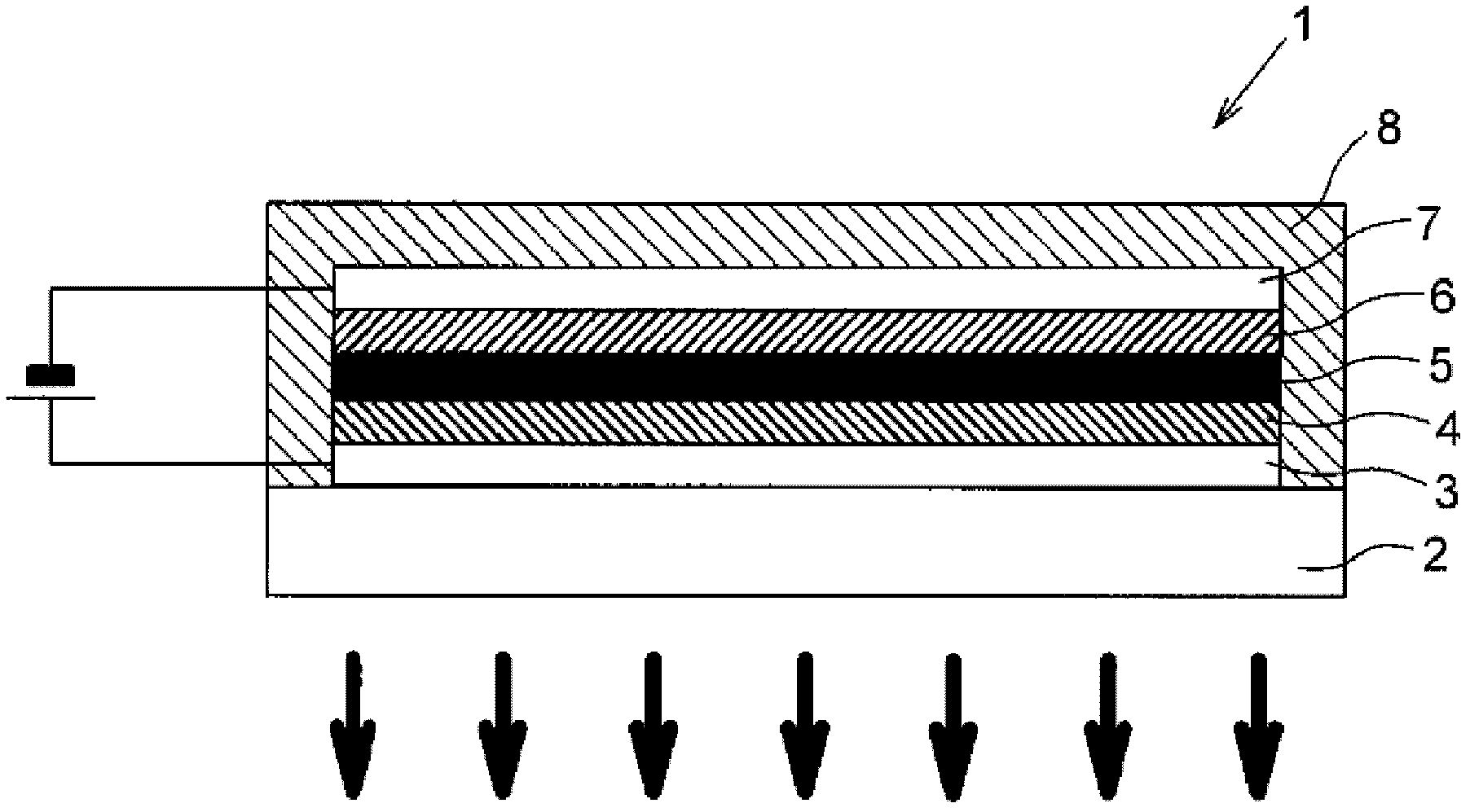

Organic electroluminescent element and novel alcohol-soluble phosphorescent material

An electroluminescence element and luminescence technology, applied in the direction of electroluminescence light sources, luminescent materials, electrical components, etc., can solve the problems of necessary large-scale equipment, difficulty in precise adjustment of vapor deposition speed, and poor productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

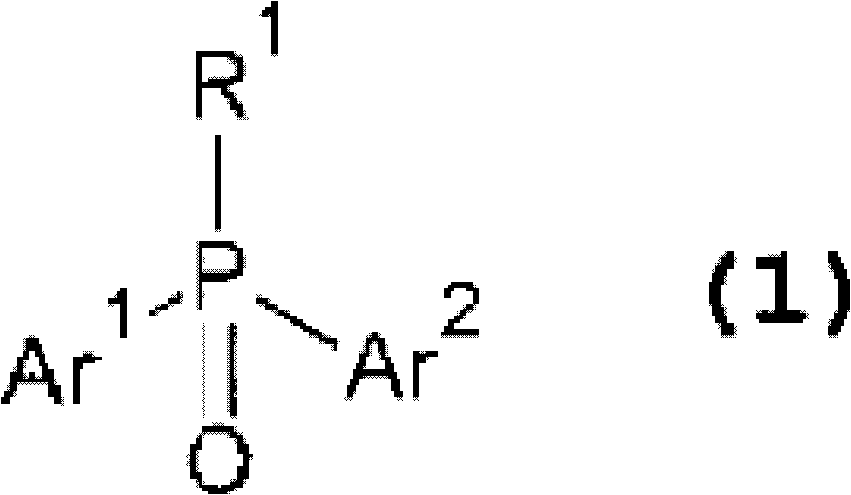

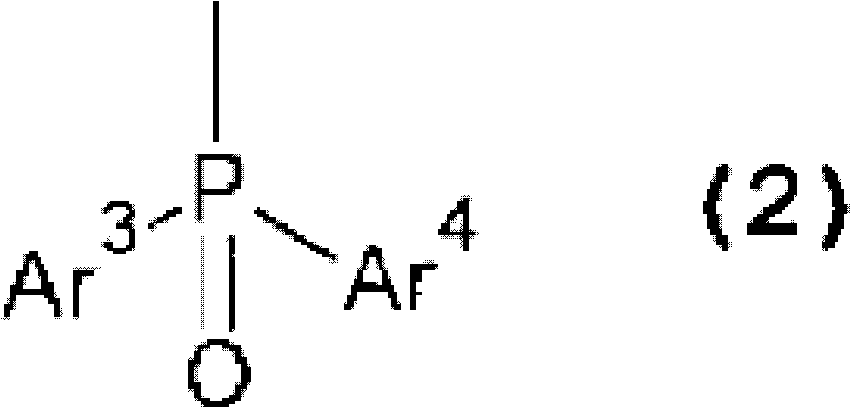

[0148] In the preparation of the composition for forming an organic electron transport material, the solutions of the respective raw materials prepared separately may be mixed. At this time, the solvents used for the respective solutions may be the same, but may be different from each other as long as a uniform solution can be obtained. Thereby, a solution can be prepared even when the solubility of the phosphine oxide derivative and the metal compound are greatly different and it is difficult to mix them in a desired quantitative ratio. Furthermore, in any one of the above methods for preparing liquid materials, mixing may also be performed so that the ratio of the host material, the guest material, and the metal salt or metal compound is a desired value. Furthermore, the content of the guest material is preferably 1 to 25% by weight relative to the host material, and the content of the metal salt or metal compound is preferably 1 to 50% by weight relative to the host materia...

Embodiment

[0235] Hereinafter, examples performed for confirming the effects of the present invention will be described.

[0236] Synthesis of host materials

[0237] The host materials used (phosphine oxide derivatives: derivatives represented by the above formulas A to Q) were synthesized according to the method described in the pamphlet of International Publication No. 2005 / 104628.

[0238] Synthesis of guest materials

[0239] [I][bis(2-phenylpyridine-N, C 2’ )-mono(2-(4-diphenylphosphorylphenyl)pyridine-N, C 2’ )] iridium(III)(Ir(ppy) 2 (pdppy)) synthesis

[0240] (I-1) Synthesis of 4-bromophenyldiphenylphosphine oxide (pBrdppo)

[0241] [chemical formula 45]

[0242]

[0243] 5 mL of THF was added to 2.16 g (88.9 mmol) of magnesium, and a THF solution of 22 g (93.2 mmol) of 1,4-dibromobenzene was added dropwise at 0°C. Stirring was performed until magnesium disappeared, 40 mL of THF was added, and further stirring was performed for 1 hour. After cooling to 0°C, 15.7 mL (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com