Spread processed cheese and method for preparing same

A processed cheese and spread-type technology, which is applied in the field of spread-type processed cheese and its preparation, can solve problems such as no spread-type processed cheese products, and achieve the effects of good flavor, stable state and excellent texture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

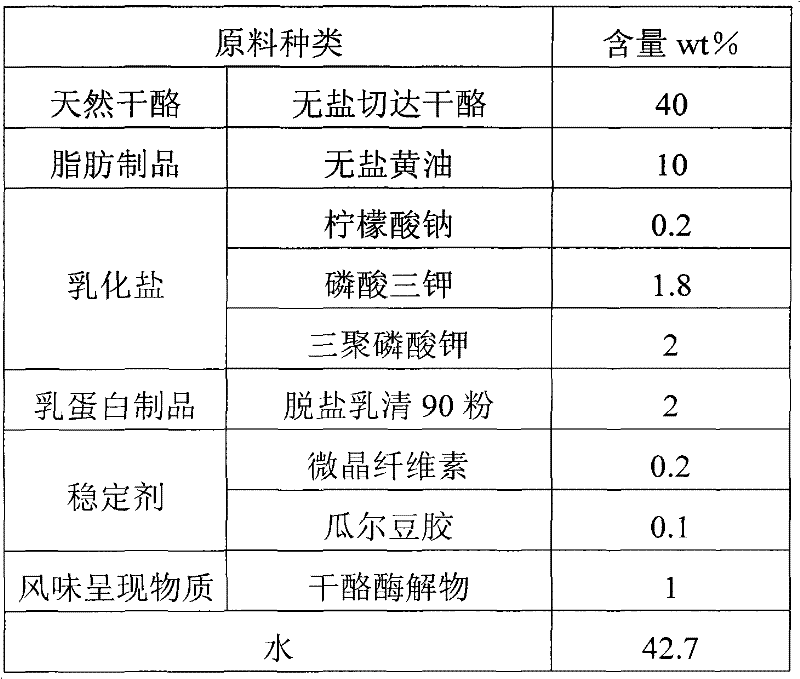

[0039] formula:

[0040]

[0041] Preparation:

[0042] ① Cut natural cheese and fat products into pieces according to the ratio of raw materials in the above table, then add the rest of the raw materials, shear and mix at a shear speed of 1800 rpm, heat up to 95°C within 10 minutes, and initially melt to obtain a mixture;

[0043] ②Homogeneous: Homogeneous pressure 20MPa;

[0044] ③Pasteurization and shearing at the same time: the sterilization temperature is 90°C, the holding time is 8 minutes; the shearing speed is 1200rpm;

[0045] ④Filling, cooling and forming: Aseptic filling is used; the finished product is cooled by soaking in running water for 30 minutes, and the product is formed when the central temperature is below 30°C.

[0046] After testing, the product indicators are: moisture 60.4%, fat 20.6%, protein 9.2%, sodium content 115mg / 100g, the above percentages are the percentages of each component in the total mass of spreadable processed cheese.

Embodiment 2

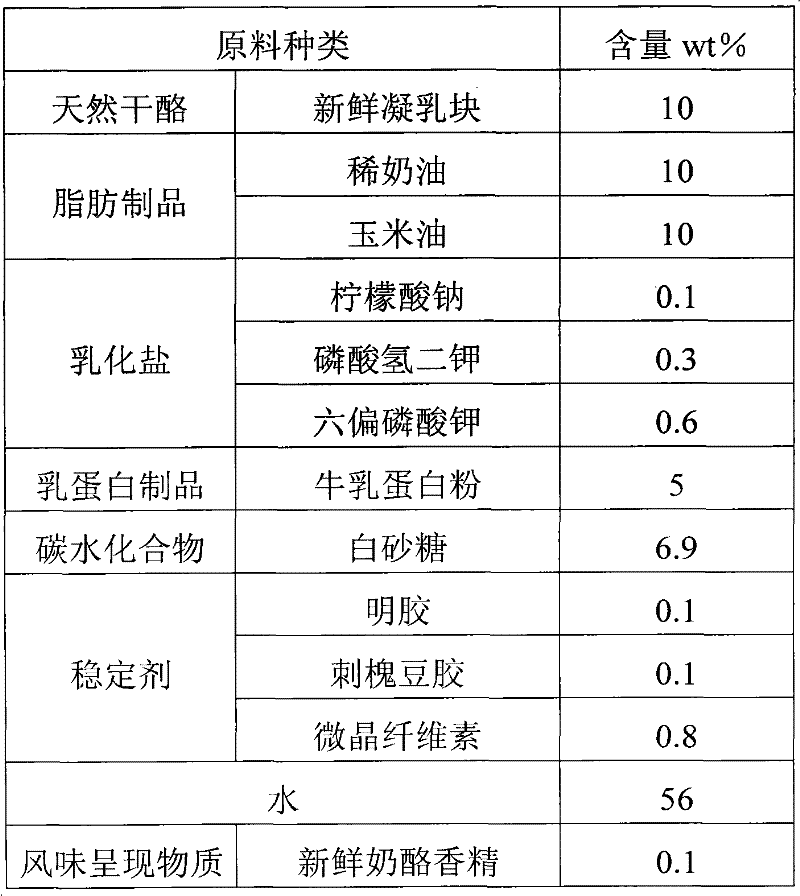

[0048] Raw material formula:

[0049]

[0050] Preparation:

[0051] ①Cut the natural cheese into pieces according to the raw material ratio in the above table, then add the rest of the raw materials, shear and mix at a shear speed of 1500 rpm, heat up to 85°C within 5 minutes and initially melt to obtain the mixture;

[0052] ②Homogeneous: Homogeneous pressure 18MPa;

[0053] ③Pasteurization and shearing at the same time: the sterilization temperature is 75°C, the holding time is 20 minutes; the shearing speed is 900rpm;

[0054] ④Filling, cooling and forming: Ultra-clean filling is used; the finished product is cooled by soaking in flowing water for 20 minutes, and the product is formed when the central temperature is below 30°C.

[0055] After testing, the product indicators are: moisture 66.0%, fat 17.1%, protein 6.0%, sodium content 118mg / 100g, the above percentages are the percentages of each component in the total mass of spreadable processed cheese.

Embodiment 3

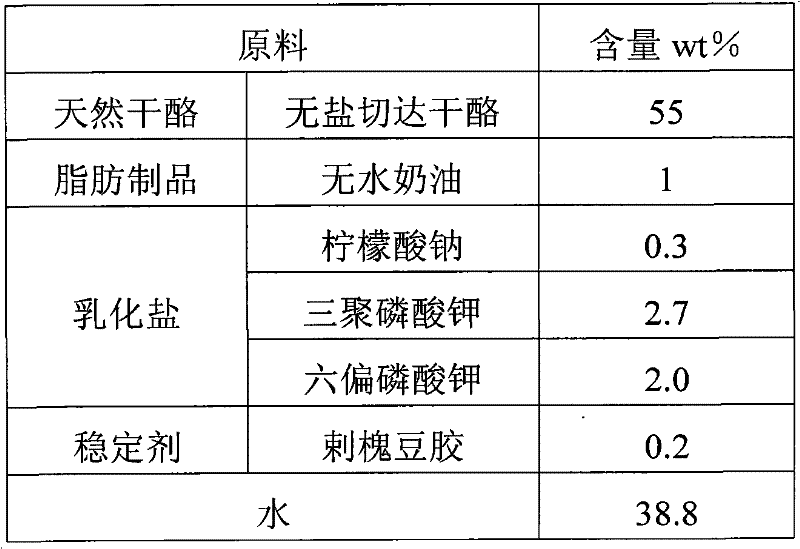

[0057] formula:

[0058]

[0059] Preparation:

[0060] ① Cut the natural cheese and fat products into pieces according to the ratio of raw materials in the above table, then add the rest of the raw materials, shear and mix at a shear speed of 2000 rpm, heat up to 90°C within 8 minutes and initially melt to obtain a mixture;

[0061] ②Homogeneous: Homogeneous pressure 30MPa;

[0062] ③Pasteurization and shearing at the same time: the sterilization temperature is 82°C, the holding time is 15 minutes; the shearing speed is 1200rpm;

[0063] ④ Filling, cooling and forming: Ultra-clean filling is used; the finished product is cooled by soaking in running water for 30 minutes, and the product is formed when the central temperature is below 25°C.

[0064] After testing, the product indicators are: moisture 61.1%, fat 18.3%, protein 12.0%, sodium content 101mg / 100g, the above percentages are the percentages of each component in the total mass of spreadable processed cheese.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com