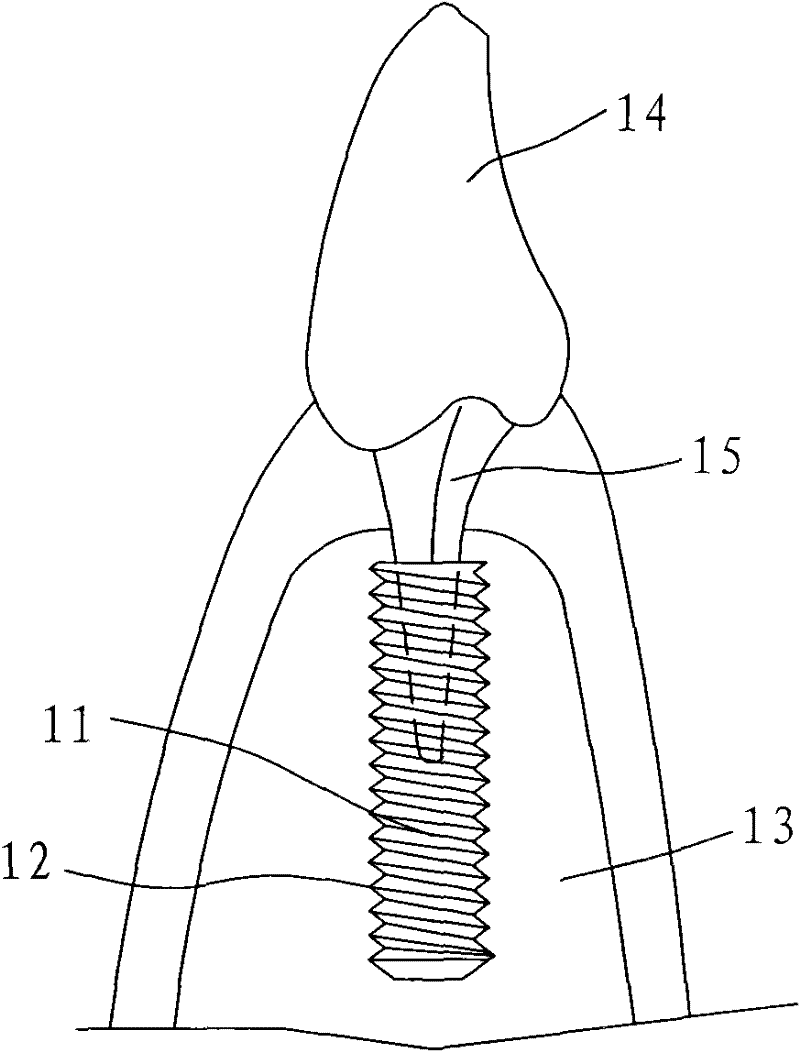

Artificial tooth root with nanostructure

A technology of nanostructure and artificial tooth root, which is applied in dentistry, dentures, dental preparations, etc., and can solve the problems of poor bonding between bone cell tissue and artificial tooth root, general products without suitable structure, and loosening.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example 1

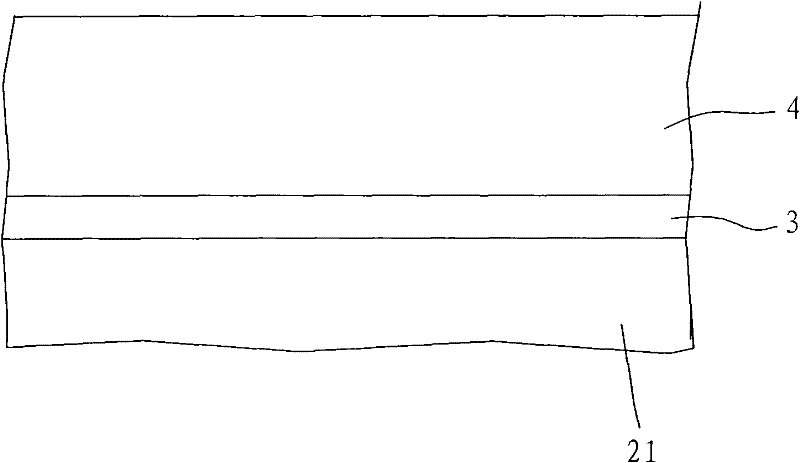

[0040] The first is to prepare the base material for the silicon wafer.

[0041] Next, a tantalum nitride (TaN) film with a thickness of 200 nm is deposited on the surface of the substrate, and then an aluminum film with a thickness of 400 nm is deposited on the top surface of the tantalum nitride film away from the substrate.

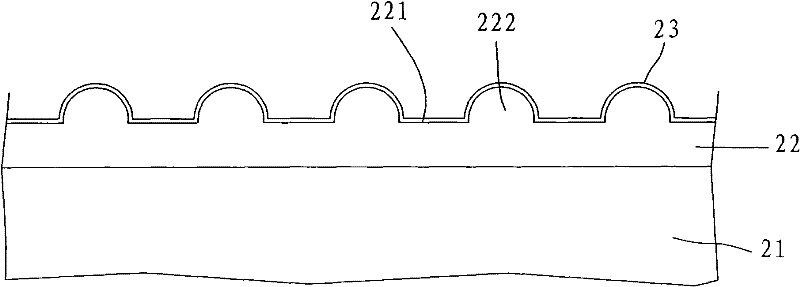

[0042] Next, prepare an electroplating solution and a power supply with two opposite electrodes. The electroplating solution is sulfuric acid with a molar concentration of 1.8M. The substrate on which the tantalum nitride film and the aluminum film are sequentially deposited is placed in the electroplating solution. , The aluminum film is used as an anode electrically connected to one of the electrodes. The power supply is used to give a voltage of 5V, and the aluminum film is anodized by electroplating to form an aluminum oxide film. The structure of the aluminum oxide film is rearranged to have A plurality of holes penetrating the bottom surface of the al...

specific example 2

[0047] The manufacturing process of this specific example 2 is roughly the same as that of the specific example 1. The difference is that the electroplating solution is oxalic acid with a molar concentration of 0.3M, and the power supply is given a voltage of 25V, which can produce an average After the aluminum oxide film with a hole with a diameter of 50 nm undergoes an oxidation reaction on a part of the tantalum nitride film exposed to the hole, the average diameter of each nano-dot is 50 nm and the average height is 50 nm.

[0048] Then, after removing the aluminum oxide film, and forming a reinforced adhesion layer with a thickness of 6 nm and made of platinum as the main material on the surface of the tantalum nitride film and the nanodot film, an artificial tooth root B with a nanostructure is obtained .

specific example 3

[0050] The manufacturing process of this specific example 3 is roughly the same as that of the specific example 1. The difference is that the electroplating solution is oxalic acid with a molar concentration of 0.3M, and the power supply is given a voltage of 100V, which can produce an average After the aluminum oxide film with a hole with a diameter of 90 nm undergoes an oxidation reaction on a part of the tantalum nitride film exposed to the hole, the average diameter of each nano-dot is 90 nm and the average height is 100 nm.

[0051] Then, after removing the aluminum oxide film, and forming a reinforced adhesion layer with a thickness of 6 nm and made of platinum as the main material on the surface of the tantalum nitride film and the nanodot film, an artificial tooth root C with a nanostructure is obtained .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com