Preparation method of carbon coated magnetic nano-spherical iron sulfide

A magnetic nanometer and iron sulfide technology, which is applied in the preparation of microspheres, the magnetic properties of inorganic materials, and the preparation of microcapsules, can solve the problems of high reaction temperature, complicated process and equipment, and achieve the effect of simple process and good stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

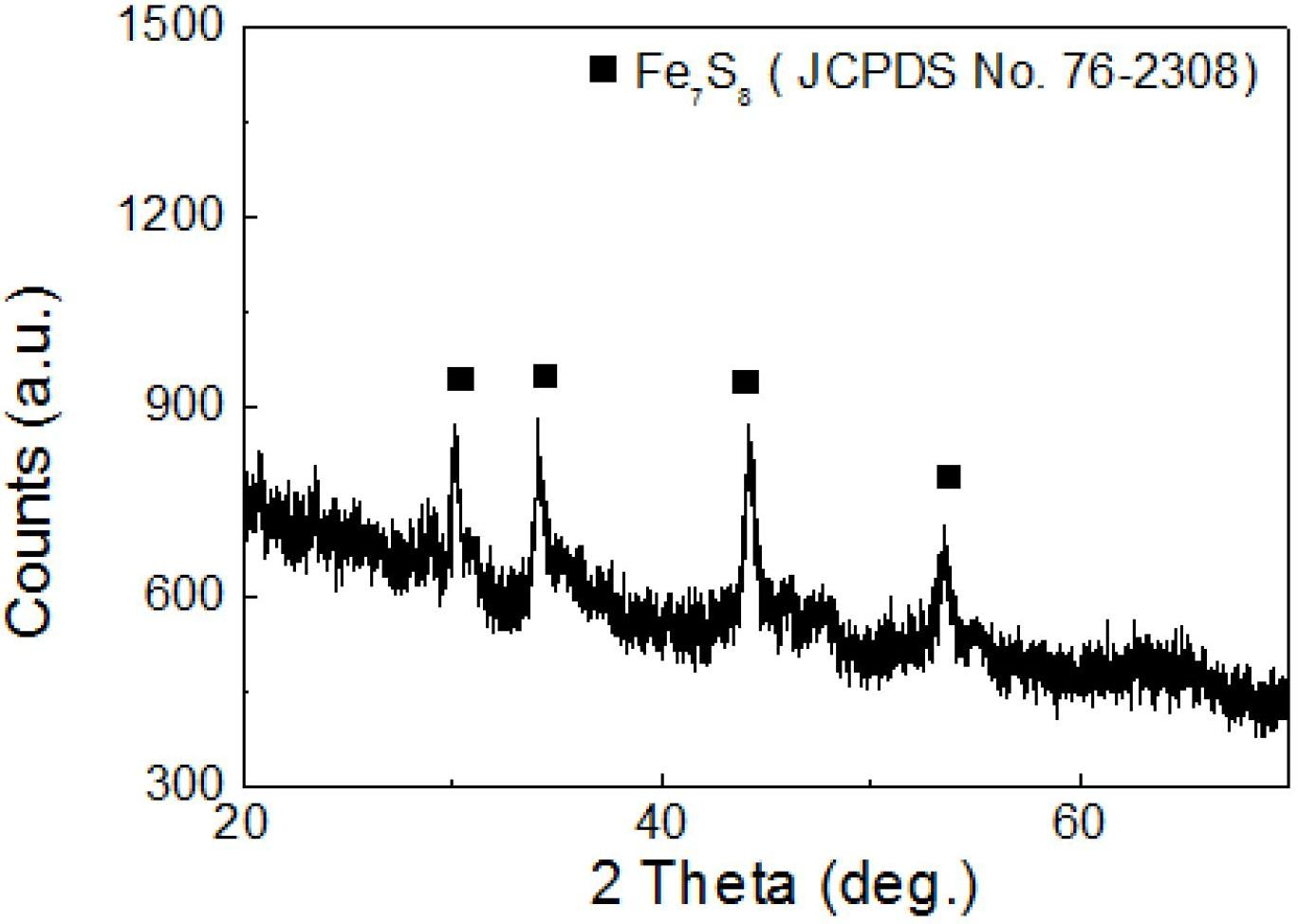

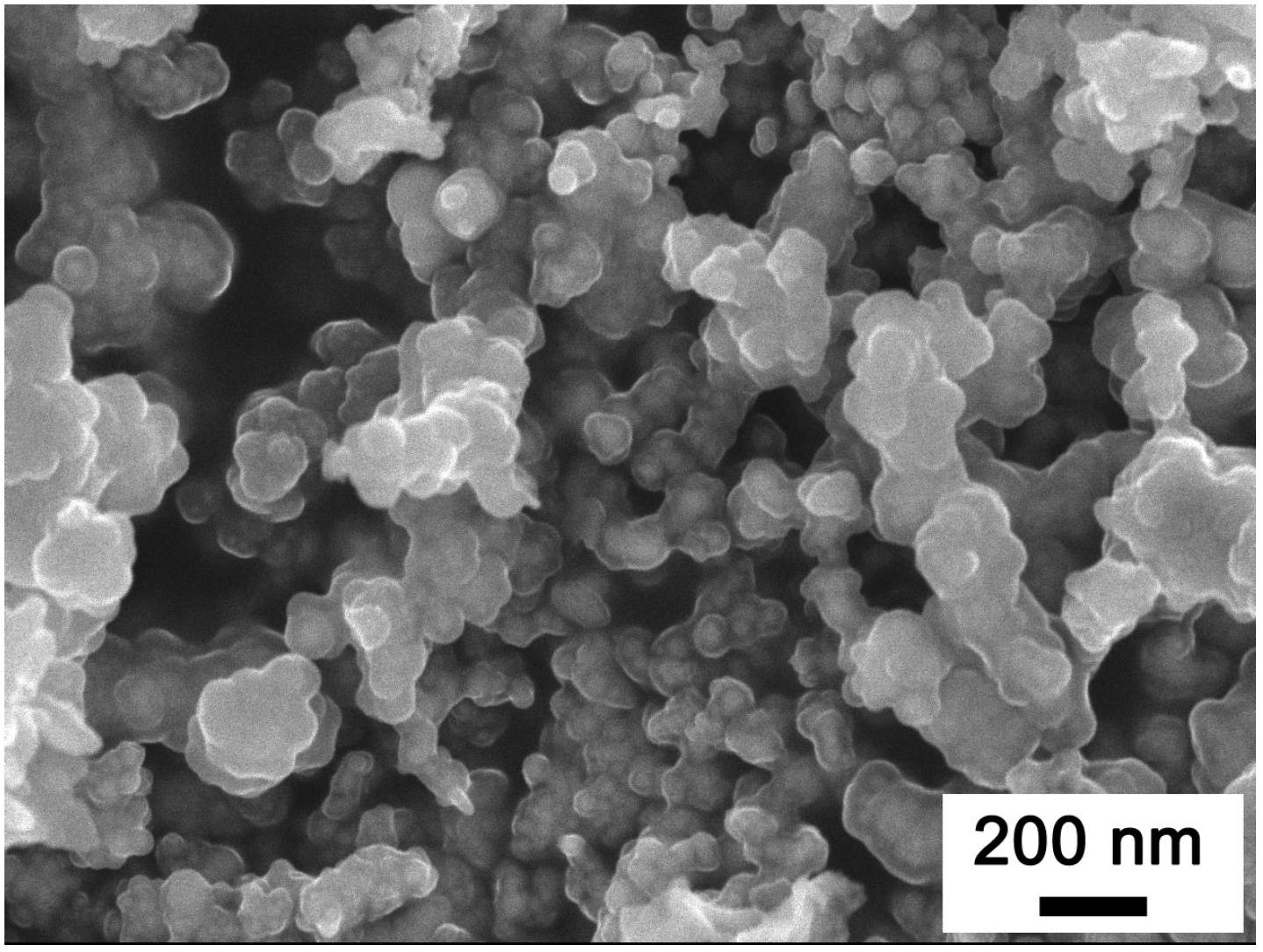

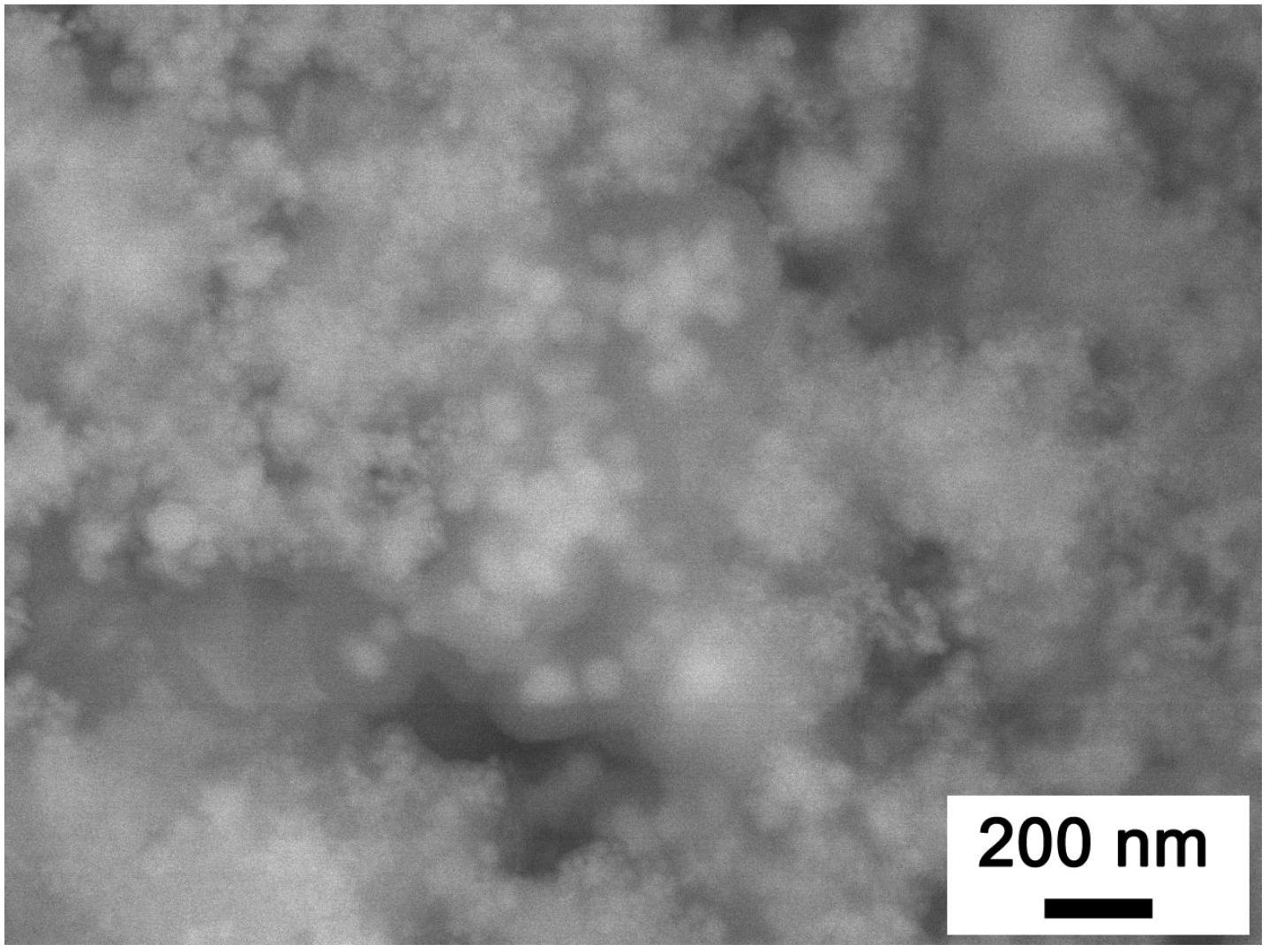

[0029] Mix 1 gram of ferrocene and 2 grams of ammonium persulfate evenly, put them into a 50 milliliter pressure bomb lined with p-polyphenylene in a glove box under a nitrogen protective atmosphere, and lock and seal it. Heat the pressure melting bomb to 200°C, keep it warm for 1 hour and then cool to room temperature. The obtained black flocculent powder was cleaned and dried with deionized water and absolute ethanol to obtain 0.69 g of carbon-coated nano-spherical Fe 7 S 8 powder.

Embodiment 2

[0031] Mix 3 grams of ferrocene and 8 grams of ammonium persulfate evenly, put them into a 50 milliliter pressure bomb lined with p-polyphenylene in a glove box under a nitrogen protective atmosphere, and lock and seal. Heat the pressure melting bomb to 200°C, keep it warm for 2 hours and then cool to room temperature. The obtained black flocculent powder was cleaned and dried with deionized water and absolute ethanol to obtain 2.46 grams of carbon-coated nano-spherical Fe 7 S 8 powder.

Embodiment 3

[0033] 2 grams of ferrocene and 4 grams of ammonium persulfate were evenly mixed, and placed in a pressure-dissolving bomb with a volume of 50 milliliters of p-polyphenyl lined in a glove box under a nitrogen protective atmosphere and locked and sealed. Heat the pressure melting bomb to 150°C, keep it warm for 4 hours and then cool to room temperature. The obtained black flocculent powder was cleaned and dried with deionized water and absolute ethanol to obtain 1.54 grams of carbon-coated nano-spherical Fe 7 S 8 powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com