Vertical-type dry-concentration placer ore taking and magnetic concentration system and method

A placer and dry separation technology, applied in chemical instruments and methods, magnetic separation, solid separation, etc., can solve the problems of low degree of automation, high energy consumption, high labor intensity, etc., to improve efficiency, reduce equipment investment, The effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

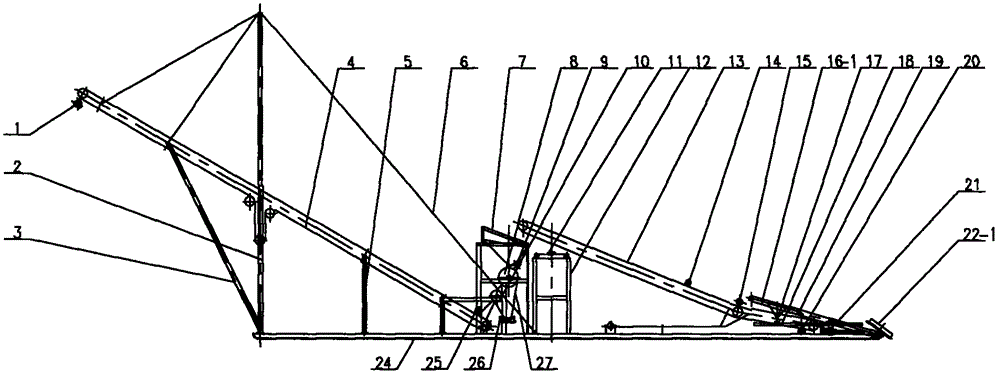

[0057] Embodiment 1: The present invention includes a dry-separation placer extraction system and method and a vertical dry-separation placer magnetic separation method;

[0058] The vertical, dry-separation sand ore extraction magnetic separation system includes an ore extraction mechanism, a sorting device and a waste ore conveying device, and the ore taking mechanism and the waste ore conveying device are connected to two ends of the sorting device.

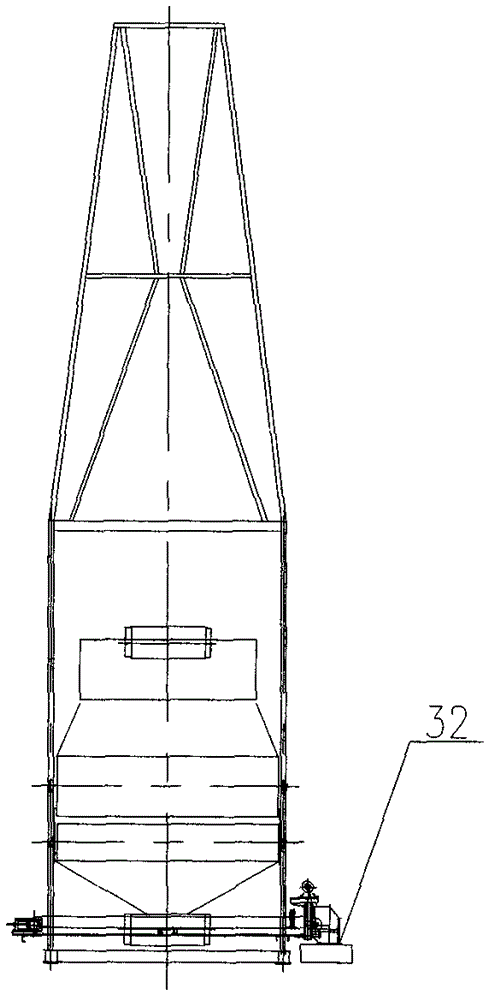

[0059] The sorting device includes: receiving hopper 7, main magnetic separation drum 8, warehouse wall vibrator 9, secondary magnetic separation drum 10, product conveyor 26, side protection aggregate 27, collection box 32; On the mobile skid body 24, the receiving hopper 7 is connected to the upper end of the fixed support, and the main magnetic separation drum 8 and the secondary magnetic separation drum 10 are connected in the fixed support, and the main magnetic separation drum 8 is located above the secondary magnetic sep...

Embodiment 2

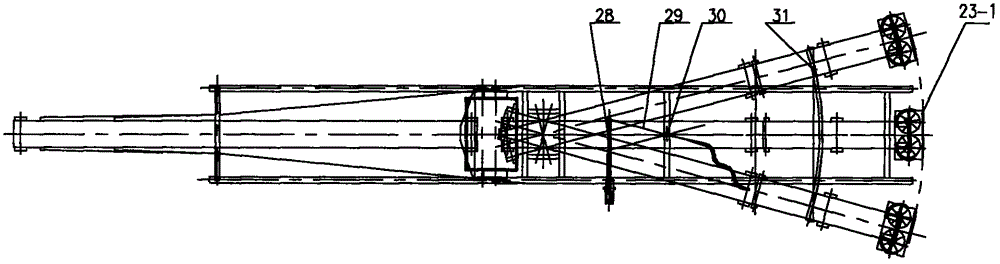

[0084] Embodiment 2: The longitudinal spiral reclaiming mechanism includes: a wear-resistant spiral reclaimer 22-2 and a reclaimer shovel cover 23-2; the wear-resistant spiral reclaimer 22-2 is coaxially connected with the helical blade of the screw conveyor , (the wear-resistant screw reclaiming head screw is slightly larger than the screw size of other parts), the support of the reclaiming shovel cover 23-2 is fixedly connected to the screw conveyor shell to form a screw conveyor assembly; the longitudinal screw reclaiming mechanism has Two screw conveyors are arranged side by side, and two wear-resistant screw feeding heads are respectively installed on the two screw conveyors, and the upper end of each screw conveyor is connected with a motor and a reducer. Others are the same as in Example 1.

Embodiment 3

[0085] Embodiment 3: the described horizontal spiral reclaiming mechanism has a spiral reclaimer and a support, and a horizontal screw conveyor is arranged on the support, and there are coaxial left and right spiral blades in the horizontal screw conveyor, and one end of the horizontal screw conveyor is connected to the motor and deceleration connection. Only one horizontal spiral reclaiming mechanism is required, which can be connected with a small belt conveyor to realize retrieving after replacing the double-wheel reclaiming mechanism with that in Embodiment 1. Others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com