Molding method for milling large module gear for wind power generation

A forming method and gear technology, applied in the field of gear milling and forming, can solve problems such as low work efficiency and inability to meet the production needs of large quantities of bearings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

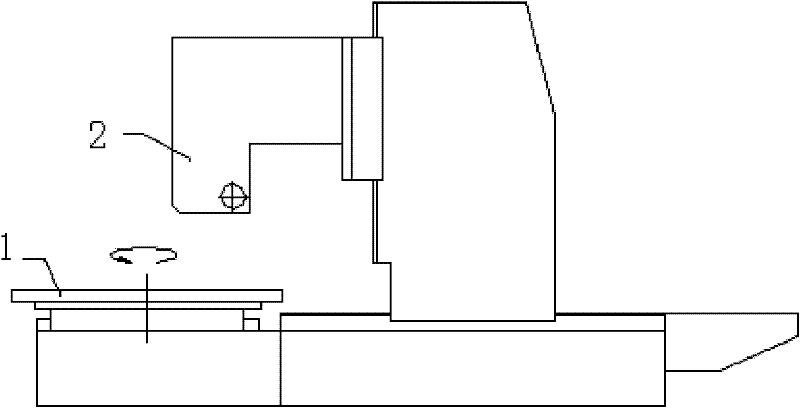

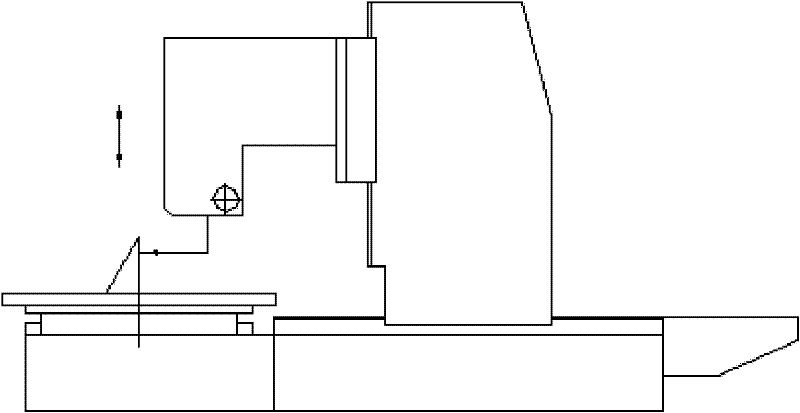

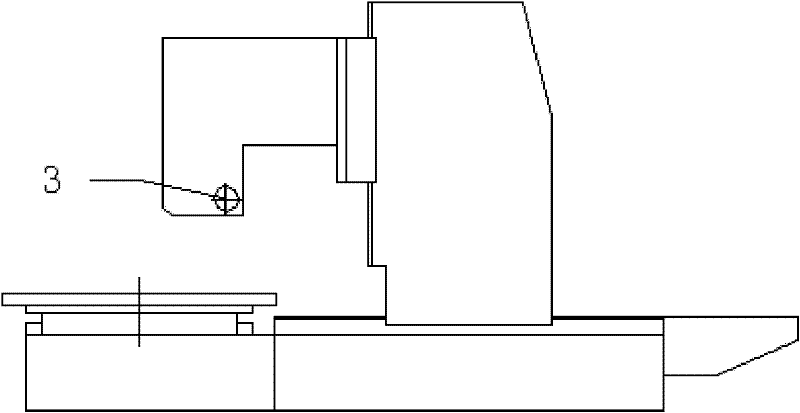

[0016] Such as Figure 1-Figure 4 As shown, the SKXC-4000 / 35N gear milling machine table 1 produced by Nanjing University of Technology is started and operated in the normal way, and its repeat positioning accuracy is measured as a unit of 60°. Adjust the slow speed to ensure that the indexing accuracy of the final machine tool is within ±10″;

[0017] Fix the additional motorized spindle 2 on the gear box of the gear milling machine, and adjust the motorized spindle to be perpendicular to the workbench 1. Use the milling cutter or grinding wheel attached to the motorized spindle to correct the tabletop, so as to ensure that the tabletop of the gear milling machine is consistent with the milling cutter. Vertical, when correcting, ensure that the flatness of the work surface is less than 0.05mm, and the verticality is ≤0.03mm;

[0018] Fix the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com