Fabricating method of thermal conducting halogen-free binderless copper clad foil

A production method and technology of copper clad foil, applied in chemical instruments and methods, lamination auxiliary operations, devices for coating liquid on the surface, etc., can solve problems such as electronic product crashes and affect the performance of electronic products, and achieve heat dissipation Good, guaranteed application performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

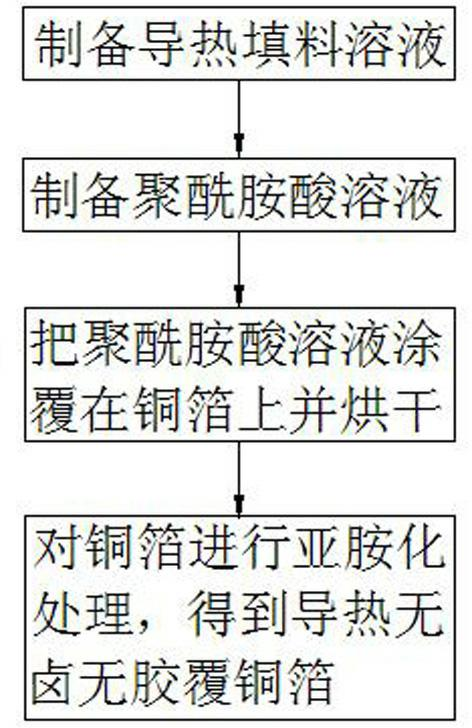

[0018] Such as figure 1 The present invention shown is a method for manufacturing heat-conducting, halogen-free, adhesive-free copper-clad foil, the method includes the following steps, specifically:

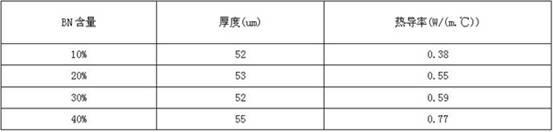

[0019] (1) Add a certain amount of thermally conductive filler into a container containing an aprotic polar solvent, and add a certain amount of glass beads at the same time, and disperse evenly on a disperser for 6 hours to obtain a thermally conductive filler solution for use. Wherein, the aprotic polar solvent is dimethylformamide, dimethylacetamide, N-methylpyrrolidone or dimethylsulfoxide. The thermally conductive filler is boron nitride or aluminum oxide or a mixture of boron nitride and aluminum oxide.

[0020] (2) Weigh a certain amount of diamine monomer and dissolve it in an aprotic polar solvent, add the thermally conductive filler solution obtained in step (1) under high-speed stirring and stir for 1.5 to 2.5 hours, specifically 2 hours , adding a dianhydride monom...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com