Intelligent conveying system

A technology of intelligent conveying and conveying system, applied in the field of conveying system, can solve the problems of no monitoring function and fault reminder function, unable to guarantee the normal operation of the conveying system at all times, inconvenient use, etc. The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

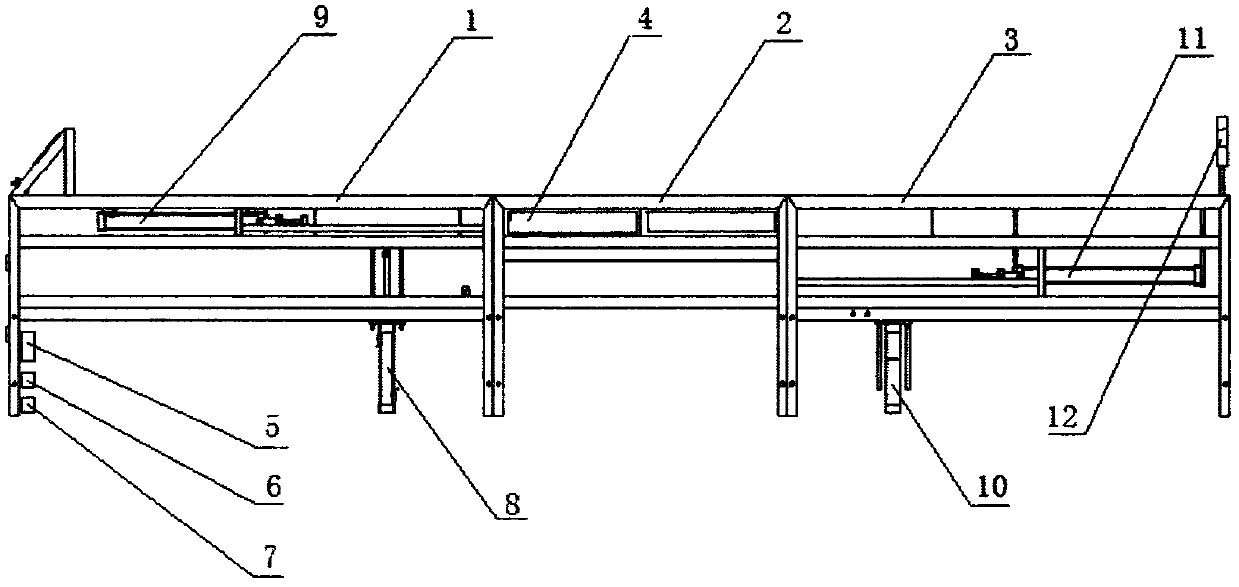

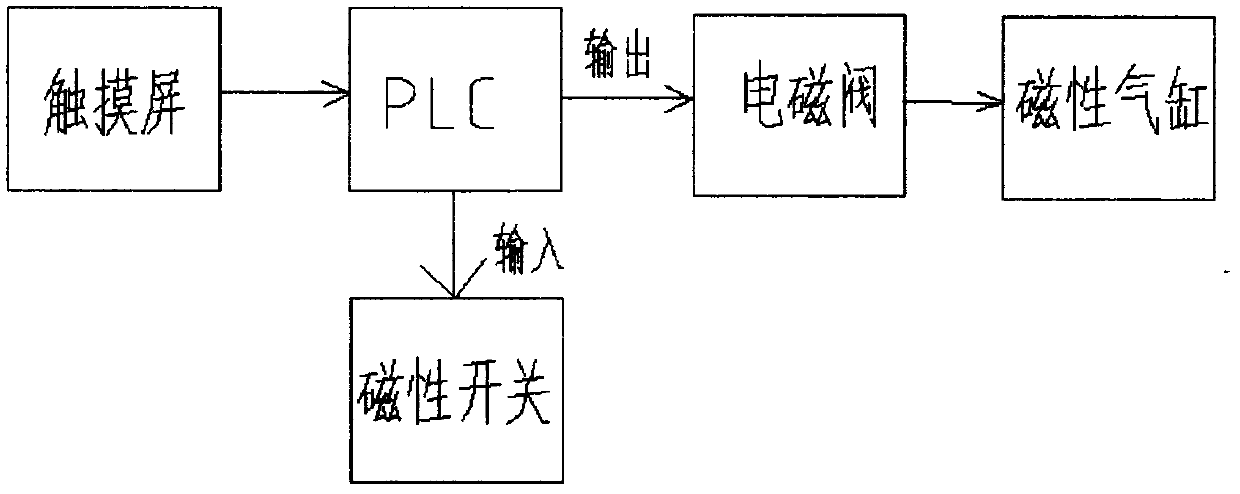

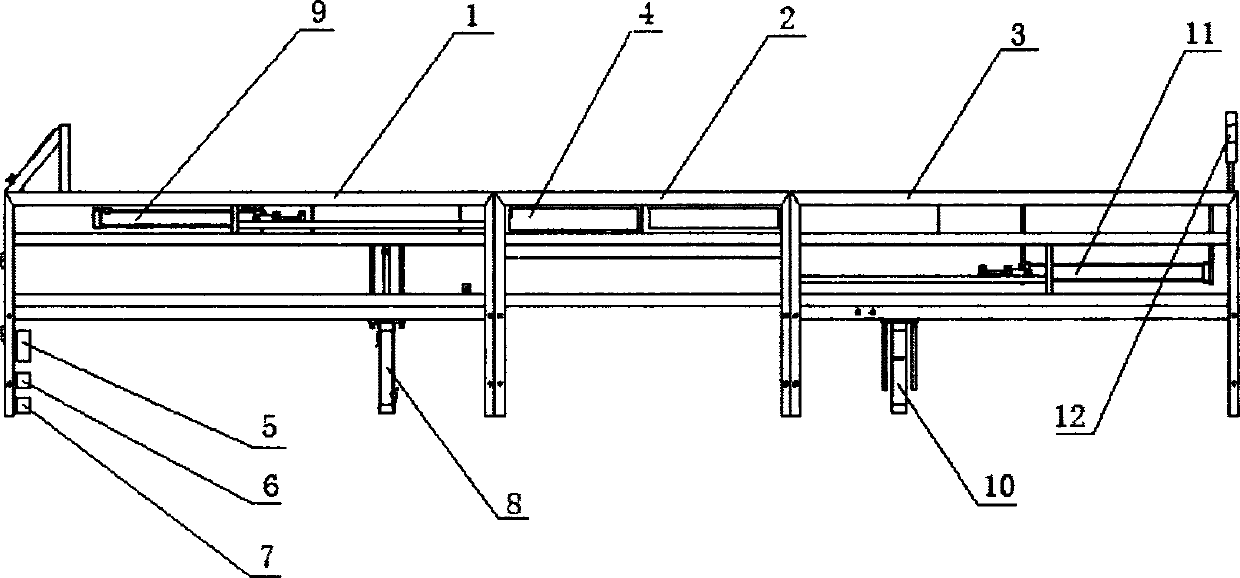

[0015] Such as figure 1 An intelligent conveying system is shown, and the conveying system is composed of a head end frame 1, a plurality of single-section frames 2 and a tail end frame 3; All are equipped with a conveying tray 4 that runs through the linkage. On the inner side of the supporting foot of the head frame 1, a PLC 5 controlling the entire conveying system, a solenoid valve group 6 and a low air pressure alarm device 7 are installed. The head frame 1 is close to the single frame 2. One end is provided with the first magnetic cylinder 8 for lifting the conveying tray and the second magnetic cylinder 9 for traversing the conveying tray, and the third magnetic cylinder 10 and the fourth magnetic cylinder 11 corresponding to the head end frame are fixedly installed on the tail end frame, A corresponding magnetic switch is provided on each magnetic cylinder.

[0016] The outer sides of the frame at the head end frame 1 and the frame at the end end 3 are provided with l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com