Artificial lens synthetic mica

A technology for synthesizing mica and artificial crystals, applied in the field of mica, can solve the problems of high temperature resistance and higher requirements, and achieve the effects of high corrosion resistance, improved service life and high mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

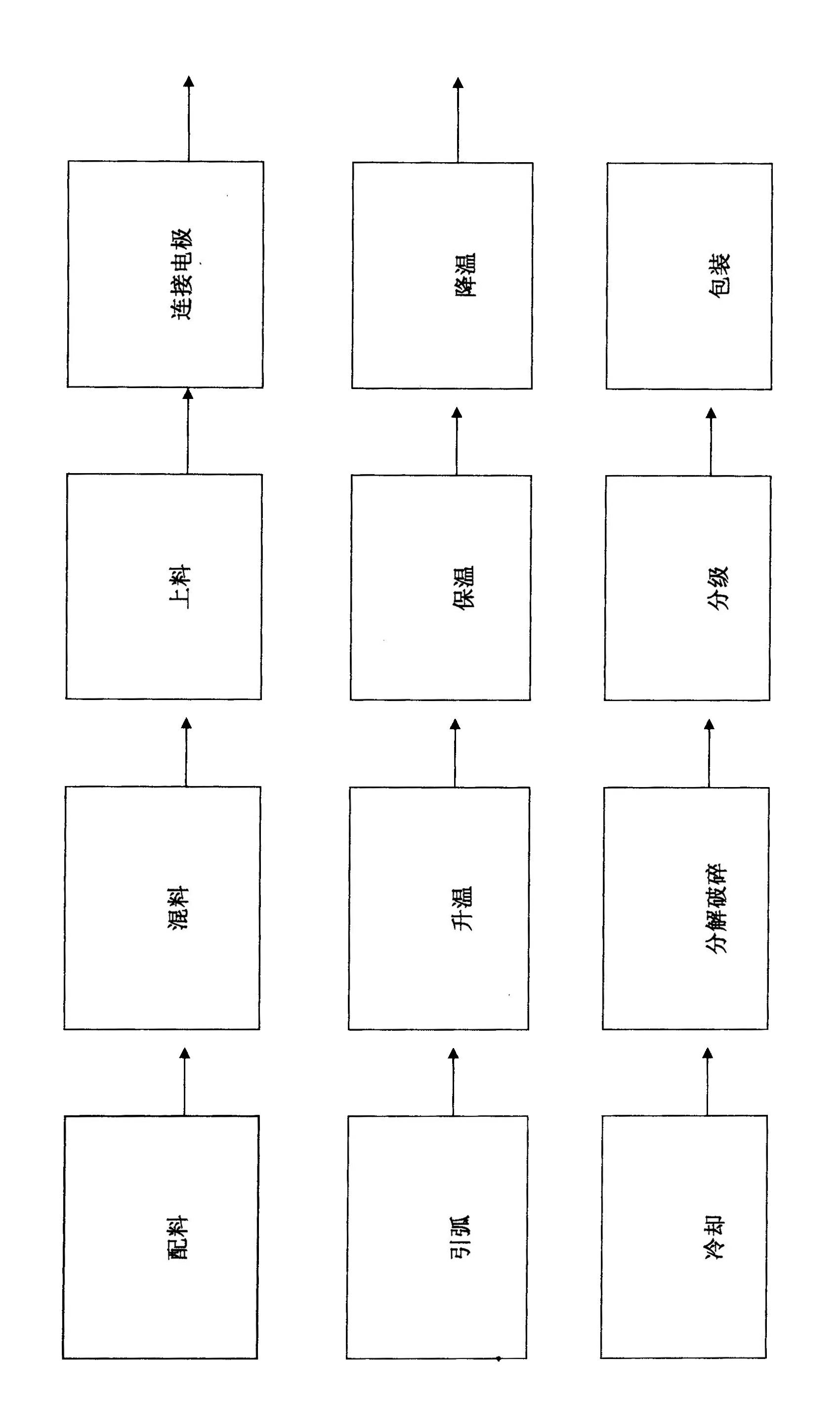

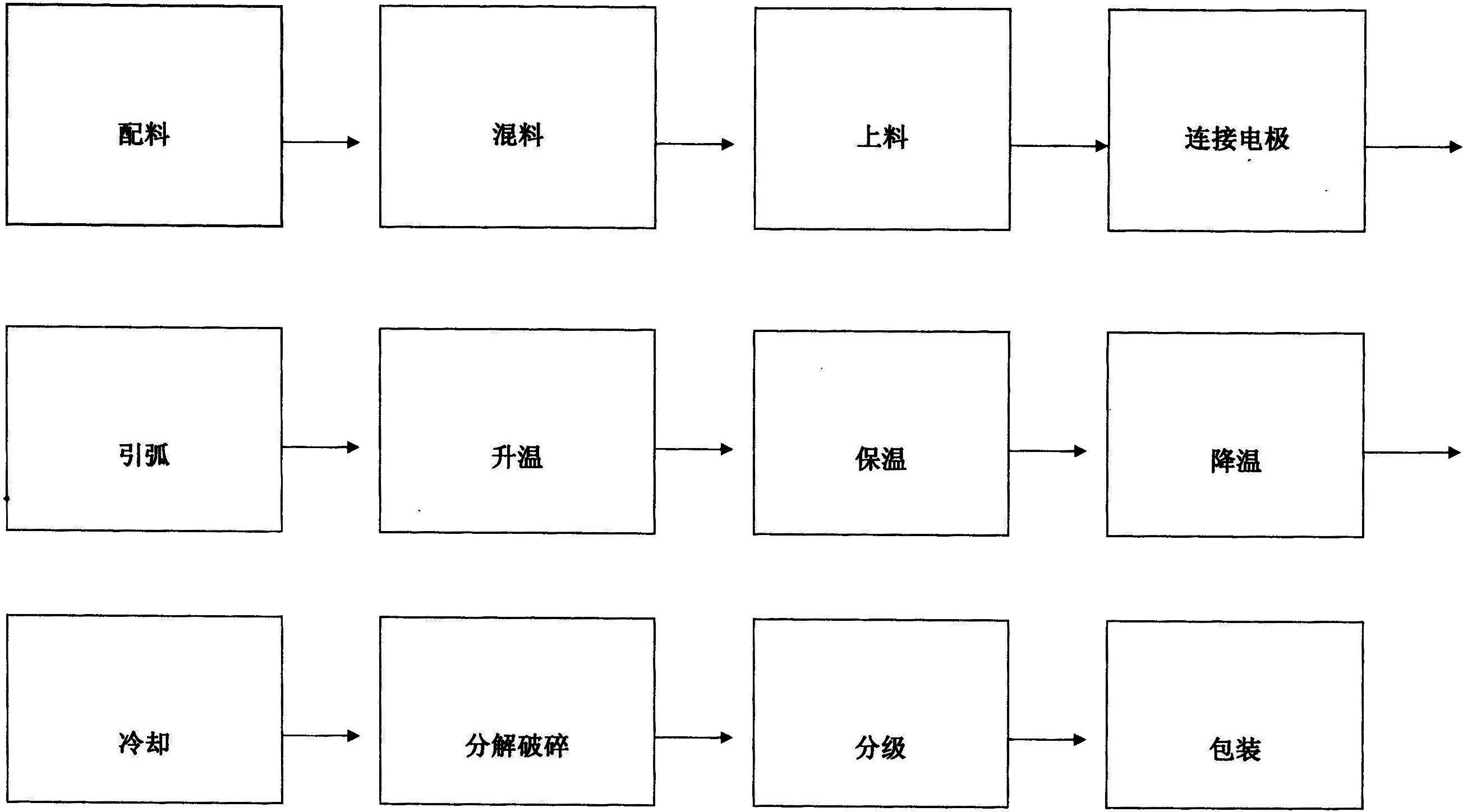

Method used

Image

Examples

Embodiment 1

[0031] 1. Proportioning 10 tons of materials, the weight percentage usage of each raw material is: 34.5% quartz sand, 12.5% alumina, 28.5% fused magnesia, 19.5% potassium fluorosilicate and 5% carbonic acid Potassium, prepare and put into the mixing equipment and stir and mix evenly for later use.

[0032] 2. Make a container: build a circular container with refractory bricks. The height of the container is 2.3 meters, the maximum cross-sectional diameter in the middle is 2.5 meters, and the cross-sectional diameter of the upper and lower ends is 2.2 meters. ×1000×50mm heating electrode, and set a 85×100mm round heating rod in the container to connect with a 40×100mm round heating vertical rod, and finally connect a 40×100mm round heating rod with an 8mm arc striking electrode rod Vertical stick.

[0033] 3. Add the raw materials that have been uniformly stirred and mixed in the first step into the above-mentioned container, connect the three-phase power supply, and conduct...

Embodiment 2

[0039] 1. Proportioning 15 tons of materials, the weight percentage usage of each raw material is: 35% quartz sand, 11% alumina, 29% fused magnesia, 20% potassium fluorosilicate and 5% carbonic acid Potassium, prepare and put into the mixing equipment and stir and mix evenly for later use.

[0040] 2. Make a container: build a circular container with refractory bricks. The height of the container is 2.3 meters, the maximum cross-sectional diameter in the middle is 2.5 meters, and the cross-sectional diameter of the upper and lower ends is 2.2 meters. ×1000×50mm heating electrode, and set a 85×100mm round heating rod in the container to connect with a 40×100mm round heating vertical rod, and finally connect a 40×100mm round heating rod with an 8mm arc striking electrode rod Vertical stick.

[0041] 3. Add the raw materials that have been uniformly stirred and mixed in the first step into the above-mentioned container, connect the three-phase power supply, and conduct electroth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com