Seawater corrosion inhibitor

A corrosion inhibitor and seawater technology, applied in seawater treatment, descaling and water softening, complex/solubilizer treatment, etc., can solve problems such as slow development, poor corrosion inhibition effect, and little consideration of environmental protection issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

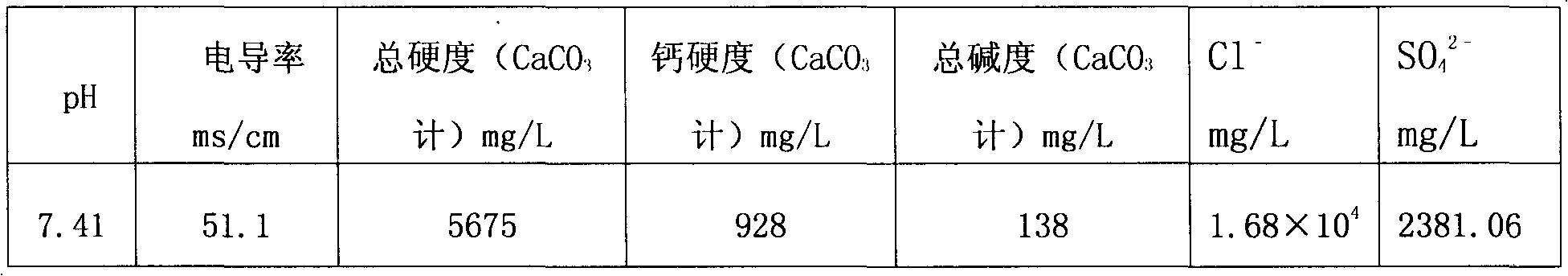

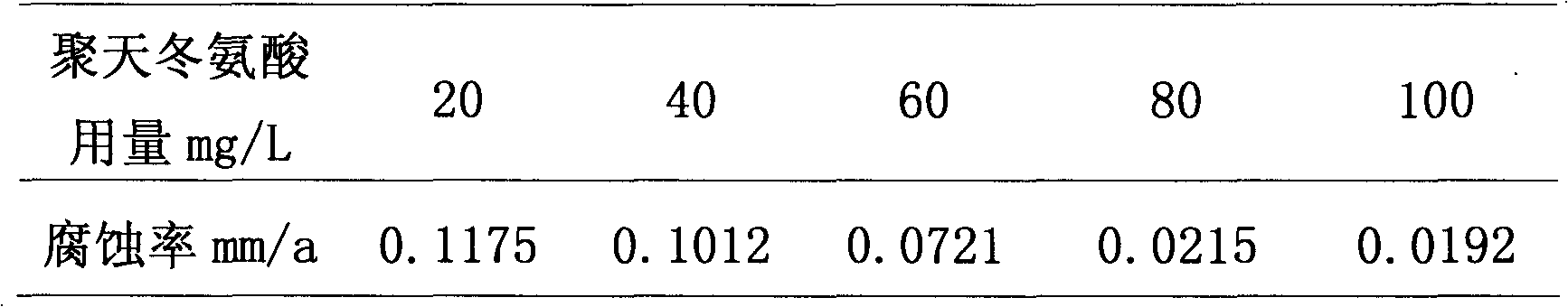

Embodiment 1

[0028] According to the mass ratio of 8:1:5:0.5, polyaspartic acid, hexadecyldimethyl (2-sulfite) ethyl ammonium, zinc sulfate and 2-hydroxyphosphonoacetic acid are compounded to form an environmentally friendly seawater buffer. Etching agent, dosage is 145mg / L. The test results show that the corrosion rate of A3 carbon steel in seawater is 0.0215mm / a, the blank corrosion rate is 0.7465mm / a, the corrosion inhibition rate is 97.12%, and the biodegradation rate after 28 days is 81.36%.

Embodiment 2

[0030] According to the mass ratio of 6:1:5:0.5, polyaspartic acid, hexadecyldimethyl (2-sulfite) ethyl ammonium, zinc sulfate and 2-hydroxyphosphonoacetic acid are compounded to form an environmentally friendly seawater buffer. Etching agent, dosage is 125mg / L. The test results show that the corrosion rate of A3 carbon steel in seawater is 0.0522mm / a, the corrosion inhibition rate is 93.01%, and the biodegradation rate after 28 days is 83.43%.

Embodiment 3

[0032] According to the mass ratio of 8:1:5:0.25, polyaspartic acid, hexadecyldimethyl (2-sulfite) ethyl ammonium, zinc sulfate and 2-hydroxyphosphonoacetic acid are compounded to make an environmentally friendly seawater buffer. Etching agent, dosage is 142.5mg / L. The test results show that the corrosion rate of A3 carbon steel in seawater is 0.0351mm / a, the corrosion inhibition rate is 95.3%, and the biodegradation rate after 28 days is 84.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Corrosion rate | aaaaa | aaaaa |

| Corrosion rate | aaaaa | aaaaa |

| Corrosion rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com