Preparation method of porous nano silicon dioxide anti-reflection film

A nano-silicon dioxide and anti-reflection coating technology, which is applied in the field of glass processing, can solve the problems of unstable film quality, expensive equipment, limitations of film materials and coated parts, etc., and achieve the effect of improving solar energy utilization efficiency and clear scenery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0022] Ordinary transparent glass is mainly composed of silicon dioxide, calcium oxide, sodium oxide and oxides of aluminum and magnesium iron, of which silicon dioxide, calcium oxide and sodium oxide account for about 95% of the total composition.

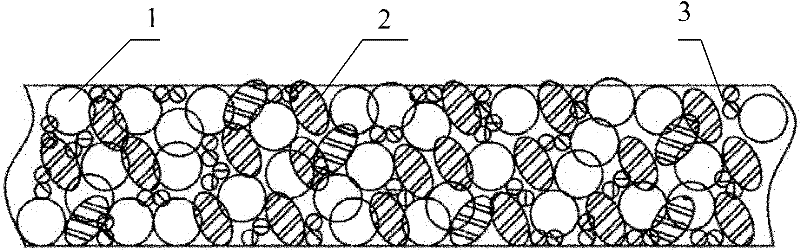

[0023] like figure 1 Shown is a schematic diagram of the molecular structure of the glass surface that has not been treated by the method of the present invention. Reference numeral 1 represents silicon dioxide molecules, reference numeral 2 represents sodium oxide molecules, and reference numeral 3 represents calcium oxide molecules.

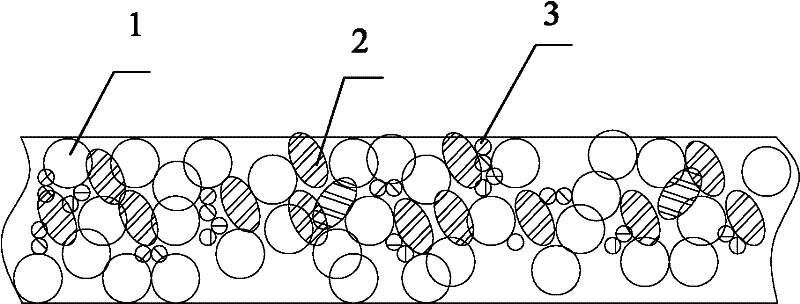

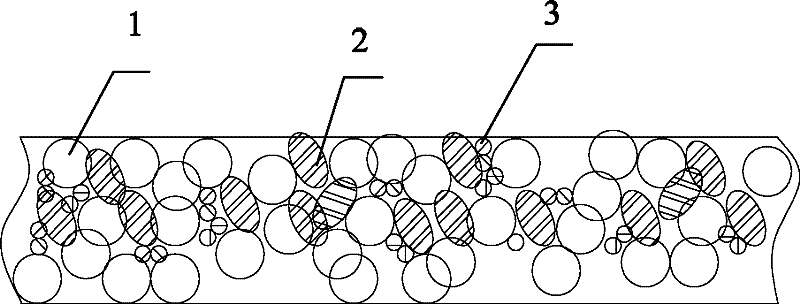

[0024] like figure 2 Shown is the schematic diagram of the glass surface molecules after...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com