Method and device for preparing 3,4-dichloroaniline without solvent

A dichloroaniline and solvent-free technology, which is applied in the field of solvent-free production of 3,4-dichloroaniline, can solve the problems of inaccurate color determination, affecting the reaction effect, affecting the increase of the load of a single kettle, and increasing the operational safety factor. The effect of low labor intensity of workers, low production cost and high level of self-control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

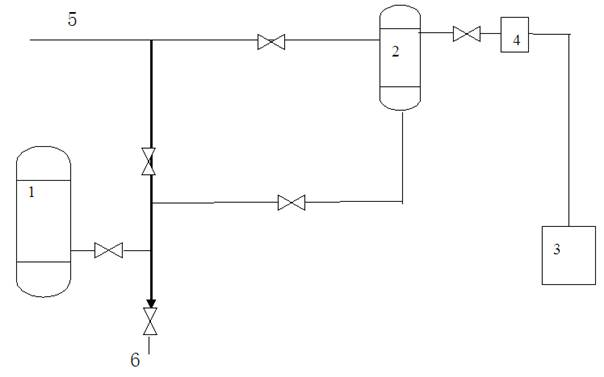

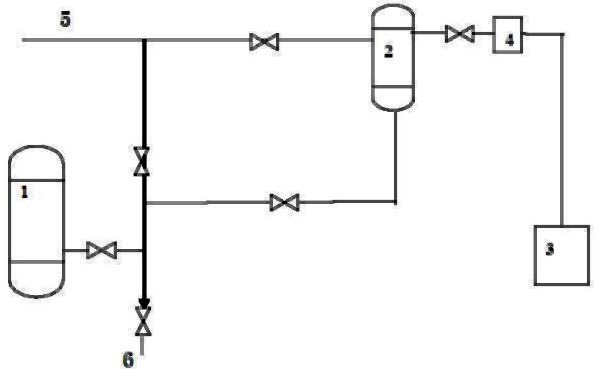

[0019] figure 1 It is a specific embodiment of the present invention. This embodiment comprises the magnetic hydrogenation kettle 1 that communicates with the hydrogen inlet pipe 5, and the hydrogenation kettle 1 and the hydrogen inlet pipe 5 are all communicated with the filter 2, and the filter 2 is communicated with the settling tank 3; the communication between the filter 2 and the settling tank 3 A pipeline sight glass 4 is installed on the pipeline; a sampling port 6 is installed at the bottom of the hydrogenation kettle 1 .

[0020] Before feeding, add anti-dechlorination inhibitor in hydrogenation kettle 1, put into hydrogenation kettle 1 then 3,4-dichloronitrobenzene, morpholine and the platinum carbon catalyst that parts by weight are 1%, at certain pressure Hydrogen gas is fed into the hydrogenation tank at a low temperature to react continuously in the hydrogenation tank. After the hydrogenation is qualified, the mixed liquid passes through the filter 2 to filter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com