Synthesizing method of epoxy resin by autocatalysis of lignin

A technology of epoxy resin and lignin, which is applied in the field of lignin utilization, can solve the problems of high-boiling alcohol lignin extraction process complexity, low extraction rate, and high cost, so as to create economic value and social value, improve safety, reduce The effect of polluting emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

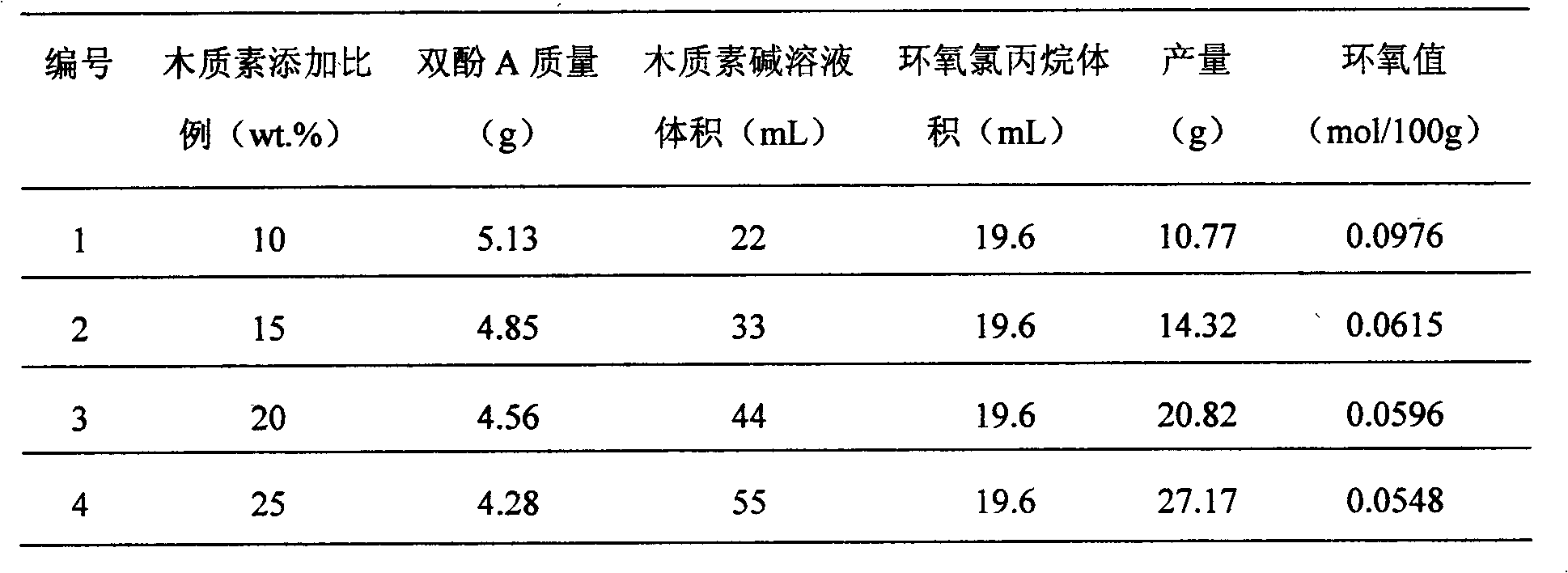

Embodiment 1

[0011] Utilize 20% mass fraction of sulfuric acid solution to adjust the pH of papermaking black liquor to 8.5, filter to remove ash and impurities, and obtain lignin alkali solution; weigh 5.13g of bisphenol A, place it in a 250mL three-necked flask, and transfer it into a 19.6mL ring Oxychloropropane, stirred in a water bath at 50°C until fully dissolved; add 1mL lignin alkali solution to the system as a catalyst, react for 30min, heat up to 90°C, then add 21mL lignin alkali solution to the solution, lignin The addition ratio is equivalent to 10wt.%, and the stirring is stopped after 1 hour of reaction; the product is filtered hot, and the filtrate is collected for vacuum distillation to remove residual moisture and excess epichlorohydrin. Finally, epoxy resin was obtained, which was a brown viscous liquid, and the yield and epoxy value were shown in Table 1.

Embodiment 2

[0013] Utilize 20% mass fraction of sulfuric acid solution to adjust the pH of papermaking black liquor to 8.5, filter to remove ash and impurities, and obtain lignin alkali solution; weigh 4.85g of bisphenol A, place it in a 250mL three-necked flask, and transfer it into a 19.6mL ring Oxychloropropane, stirred in a water bath at 50°C until fully dissolved; add 1mL lignin alkali solution to the system as a catalyst, react for 30min, heat up to 90°C, then add 32mL lignin alkali solution to the solution, lignin The addition ratio is equivalent to 15wt.%, and the stirring is stopped after 1 hour of reaction; the product is filtered hot, and the filtrate is collected for vacuum distillation to remove residual water and excess epichlorohydrin. Finally, epoxy resin was obtained, which was a brown viscous liquid, and the yield and epoxy value were shown in Table 1.

Embodiment 3

[0015] Utilize 20% mass fraction of sulfuric acid solution to adjust the pH of papermaking black liquor to 8.5, filter to remove ash and impurities, and obtain lignin alkali solution; weigh 4.56g of bisphenol A, place it in a 250mL three-necked flask, and transfer it into a 19.6mL ring Oxychloropropane, stirred at 50°C water bath temperature until fully dissolved; add 1mL lignin alkali solution to the system as a catalyst, react for 30min, heat up to 90°C, then add 43mL lignin alkali solution to the solution, lignin The addition ratio is equivalent to 20wt.%, and the stirring is stopped after 1 hour of reaction; the product is filtered hot, and the filtrate is collected for vacuum distillation to remove residual moisture and excess epichlorohydrin. Finally, epoxy resin was obtained, which was a brown viscous liquid, and the yield and epoxy value were shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com