Tea vinegar brewing method by means of multilevel fermentation and extraction

A multi-level, tea vinegar technology, applied in the preparation of vinegar, etc., can solve the problems of bad taste and taste of tea vinegar, poor anti-oxidation ability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

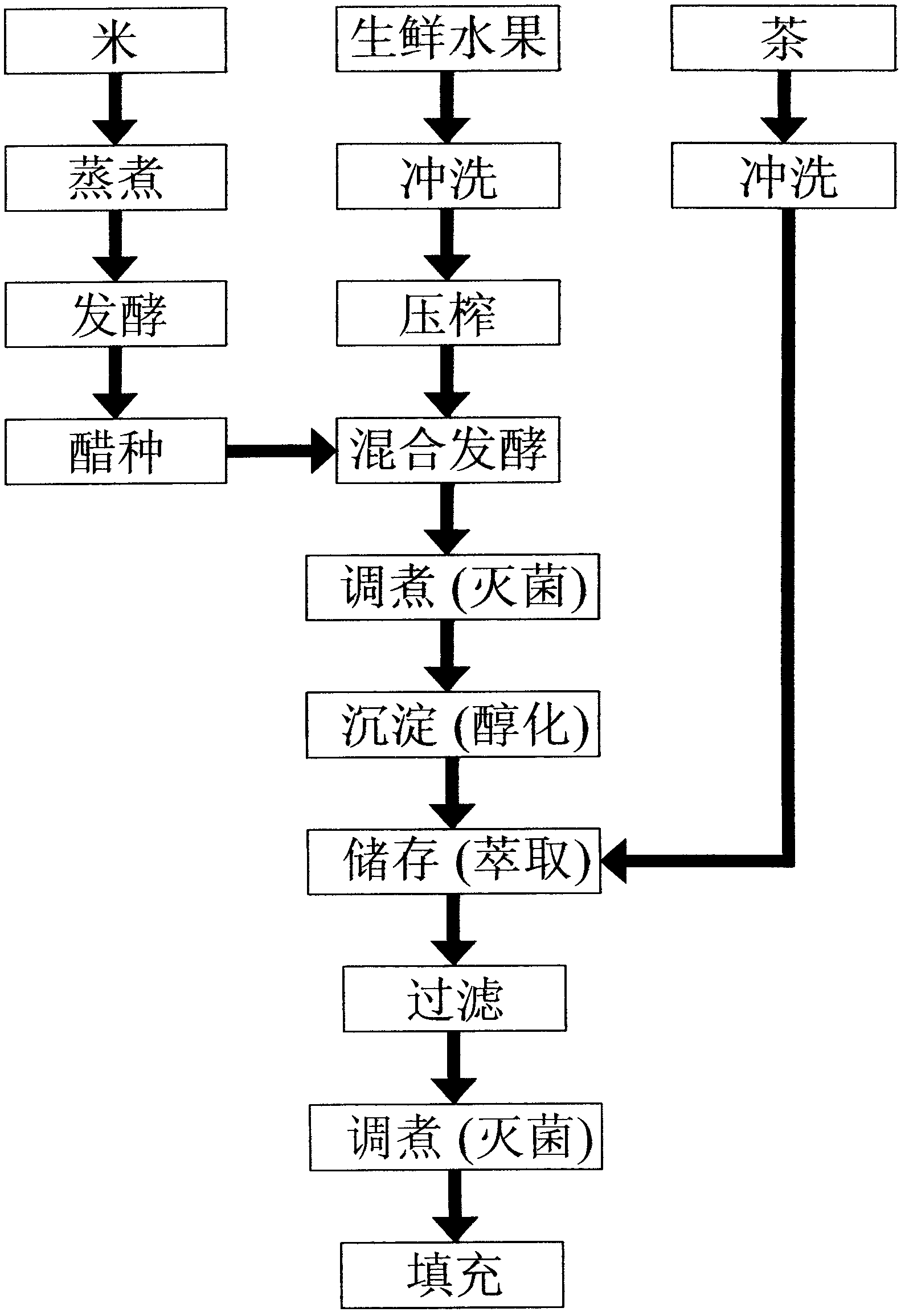

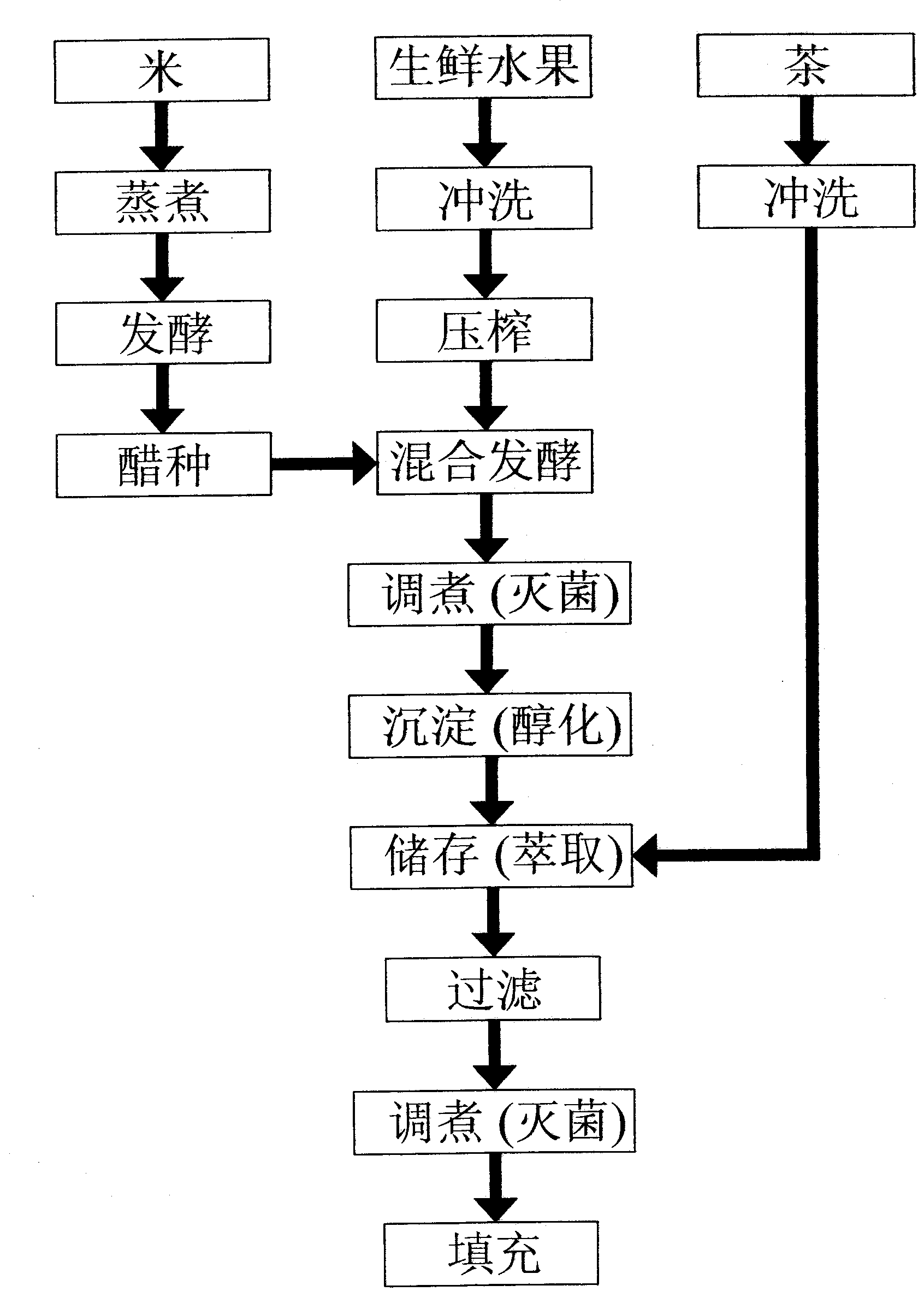

[0010] see figure 1 , the present invention is a tea vinegar brewing method based on multi-level fermentation and extraction. The main steps are to put fresh rice into wooden barrels after cooking, cooling, koji making and saccharification, etc. 3 to 6 months of high-degree fermentation make it into brewed vinegar mother (vinegar species); koji is a substance containing koji bacteria, when koji bacteria are mixed with steamed rice or wheat, sorghum, starch can be converted into glucose, producing Yeast is used to make alcohol. The raw material for making koji is pure wheat. After being ground, it is mixed with water and molded. Then the koji is cultivated in the room, air-dried out of the room, and finally stored for aging. It is ground before brewing. Standby; koji is a sour starter, saccharification agent or saccharification sour starter made from grains. Generally speaking, koji contains yeasts that can carry out alcoholization, and it contains a large number of microorgani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com