Collapse and sink intrusion limit construction method for treating wind accumulated sand loess tunnel through stride shed pipe

A technology for loess tunnels and construction methods, applied in tunnels, tunnel linings, earthwork drilling, etc., can solve the problems of poor construction safety, large construction space, and high construction costs, and achieve less harm to operators, less machinery investment, and safety. Guaranteed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The Mai-style pipe shed construction method for dealing with wind-accumulated sandy loess tunnel collapse subsidence encroachment limit construction method includes the following steps:

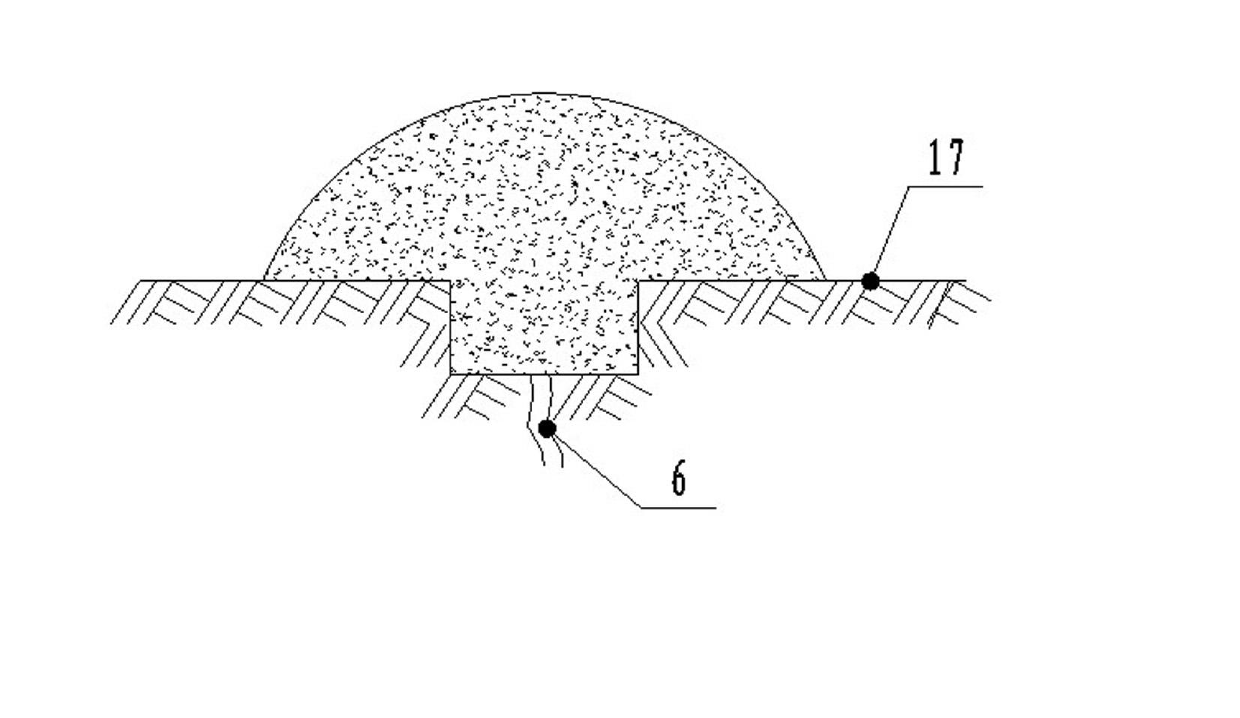

[0020] 1) Surface crack 6 treatment, in order to prevent surface water seepage and soften the soil, it is necessary to grout the surface cracks: first excavate trenches along the cracks, and then use the funnel weight method to directly grout the cracks at a distance of about 30cm 1: 1 cement slurry, after the cement slurry is filled and solidified, it is then shifted for refilling. When the amount of pouring is large, the pouring should be stopped, and the grouting should be carried out after the poured cement slurry has solidified. After grouting, the cracked ground is plastered with cement mortar and made into an arc shape to prevent rainwater from infiltrating, such as figure 1 shown.

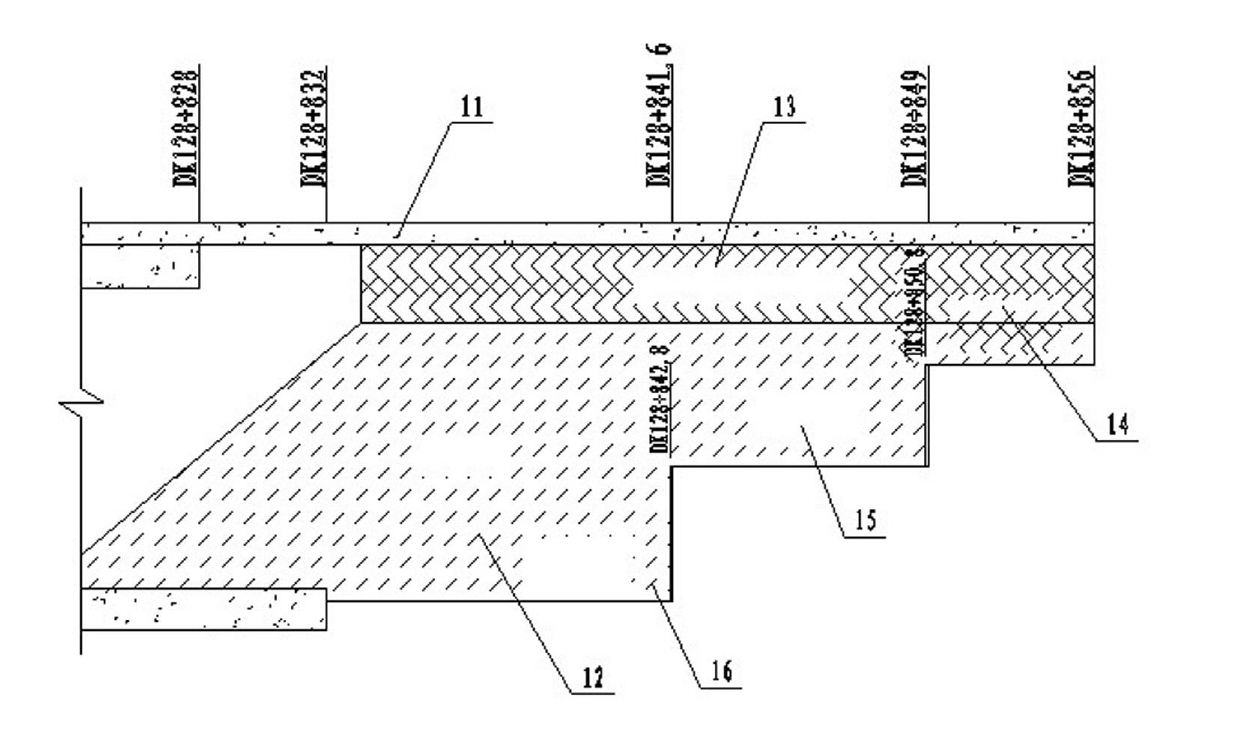

[0021] 2) Backfill in the cave, backfill the cave slag 12 in the subsidence and invasion limit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com