Injection mixing pump

A technology of injection mixing and mixing tubes, which is applied in the direction of injection pumps, pumps, non-volume pumps, etc., and can solve the problems of inappropriate high-efficiency injection mixing pumps, large axial dimensions of injectors, and unfavorable installation and use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

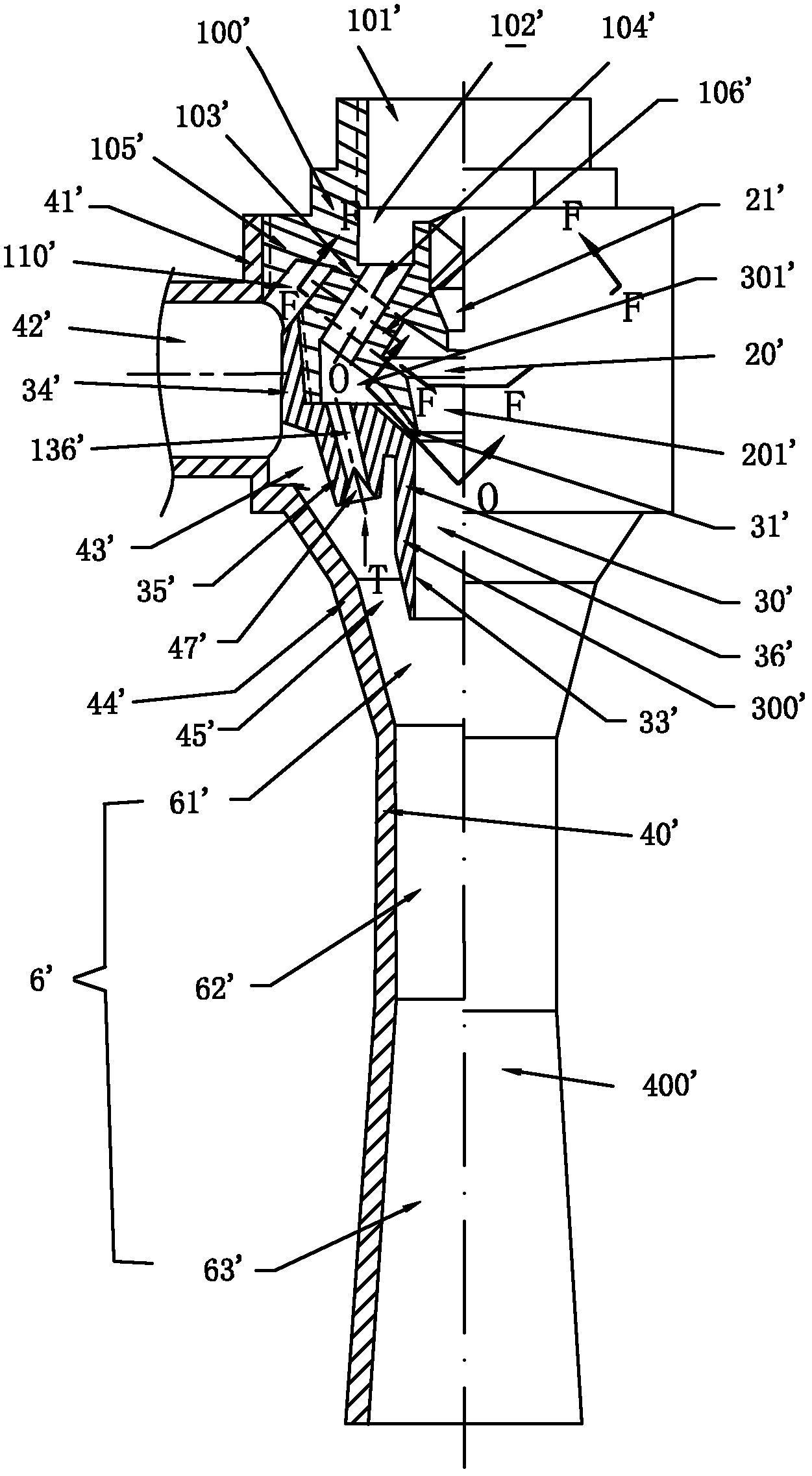

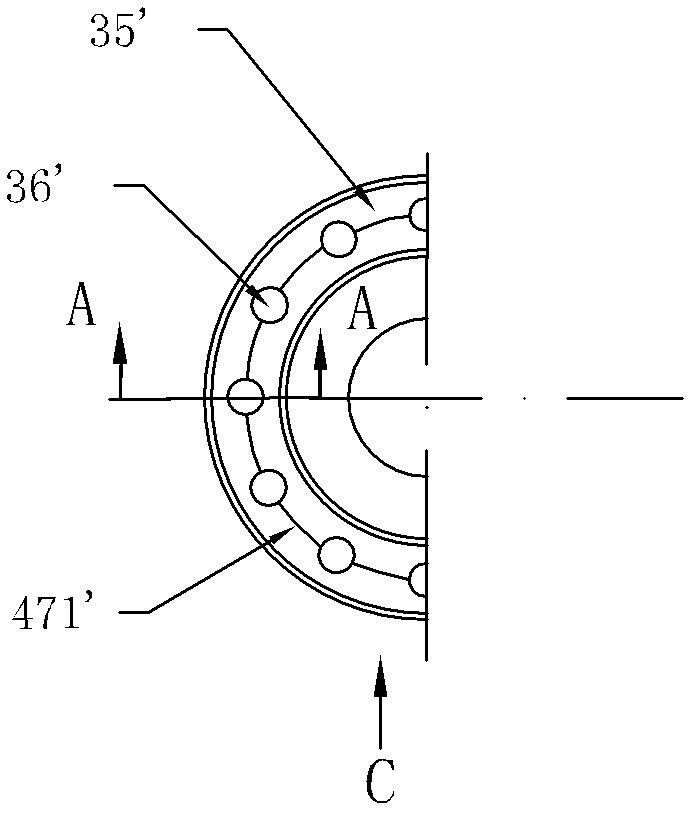

[0043] see figure 1 , the present embodiment is a jet mixing pump that injects a secondary fluid with a primary fluid and outputs a mixed fluid. The jet mixing pump is coaxially provided with an inner ring injector, an outer ring ejector and a total mixing output pipe 6' along the central axis; the inner ring injector is fixed in the outer ring ejector, and the total mixing output pipe 6' Fixed at the end of the outer ring ejector. The outlet end of the inner ring ejector and the outlet end of the outer ring ejector are smooth and straight through the total mixing output pipe 6' to form an outlet jet mixer.

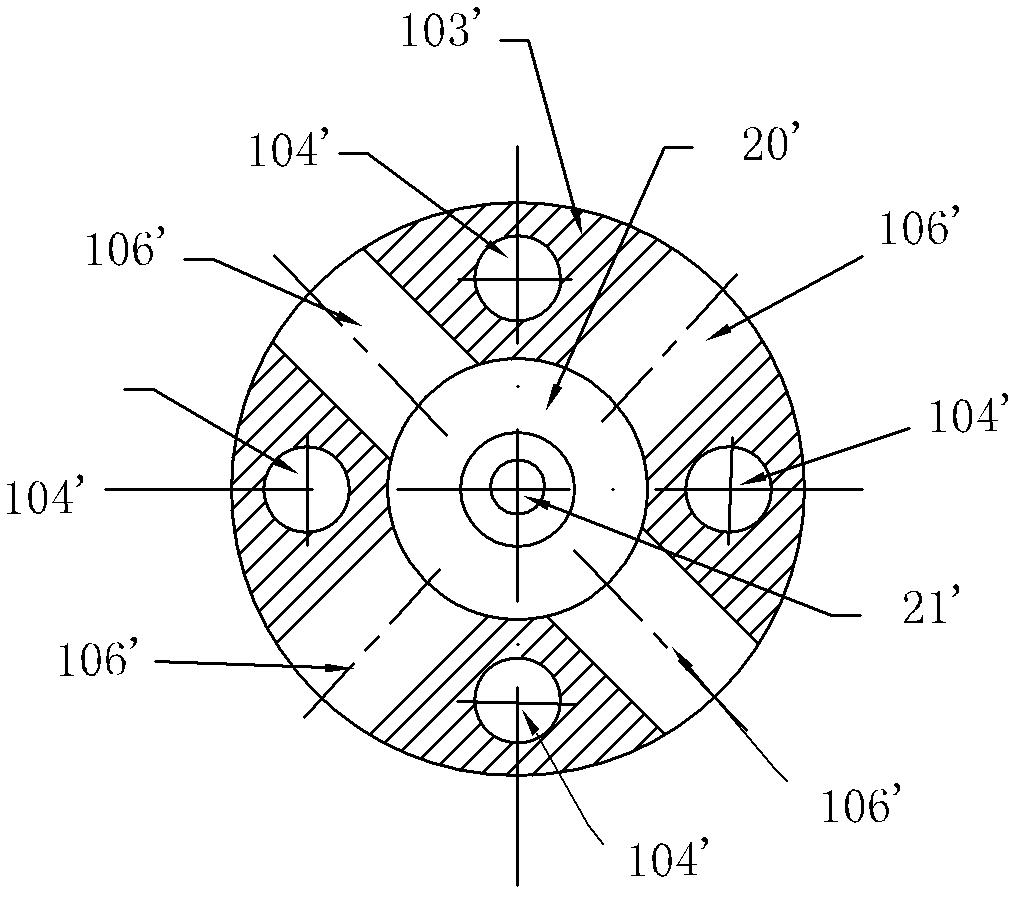

[0044] The inner ring injector is formed by butting the main fluid assembly 100', the central nozzle 21' and the inner pipe assembly 300' concentrically. A main fluid inlet pipe 101' is arranged at the center of the inlet end of the main fluid assembly 100', a tubular central nozzle 21' is arranged in the central outlet hole of the main fluid inlet pipe 101', and an out...

Embodiment 2

[0055] see Figure 7 , present embodiment is to use a kind of main fluid that imports from main fluid inlet pipe 11, introduces respectively from the first time fluid inlet 12 and the second time fluid inlet pipe 42 input two kinds of secondary fluids, from total mixing outlet pipe 6 Jet mixing pumps that output mixed fluids are especially suitable for applications where the primary fluid is liquid or liquid plus gas, and the secondary fluid is gas. The jet mixing pump is coaxially provided with an inner ring injector, an outer ring ejector and a total mixing output pipe 6 along the central axis; the inner ring injector is fixed in the outer ring ejector, and the total mixing output pipe 6 is fixed at the end of the outer ring ejector. The outlet end of the inner ring ejector and the outlet end of the outer ring ejector are smooth and straight through the total mixing output pipe 6 to form an outlet jet mixer.

[0056] The inner ring injector is formed by butting the main fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com