Automatic basic detonator grain height detection and waste rejection device and method

A technology for removing devices and basic detonators, applied to measuring devices, optical devices, instruments, etc., can solve problems such as misjudgment and missed judgment, affect detonator performance, lack of reinforcement caps, etc., to improve production efficiency and reduce waste products efficiency and improve the level of safety in production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

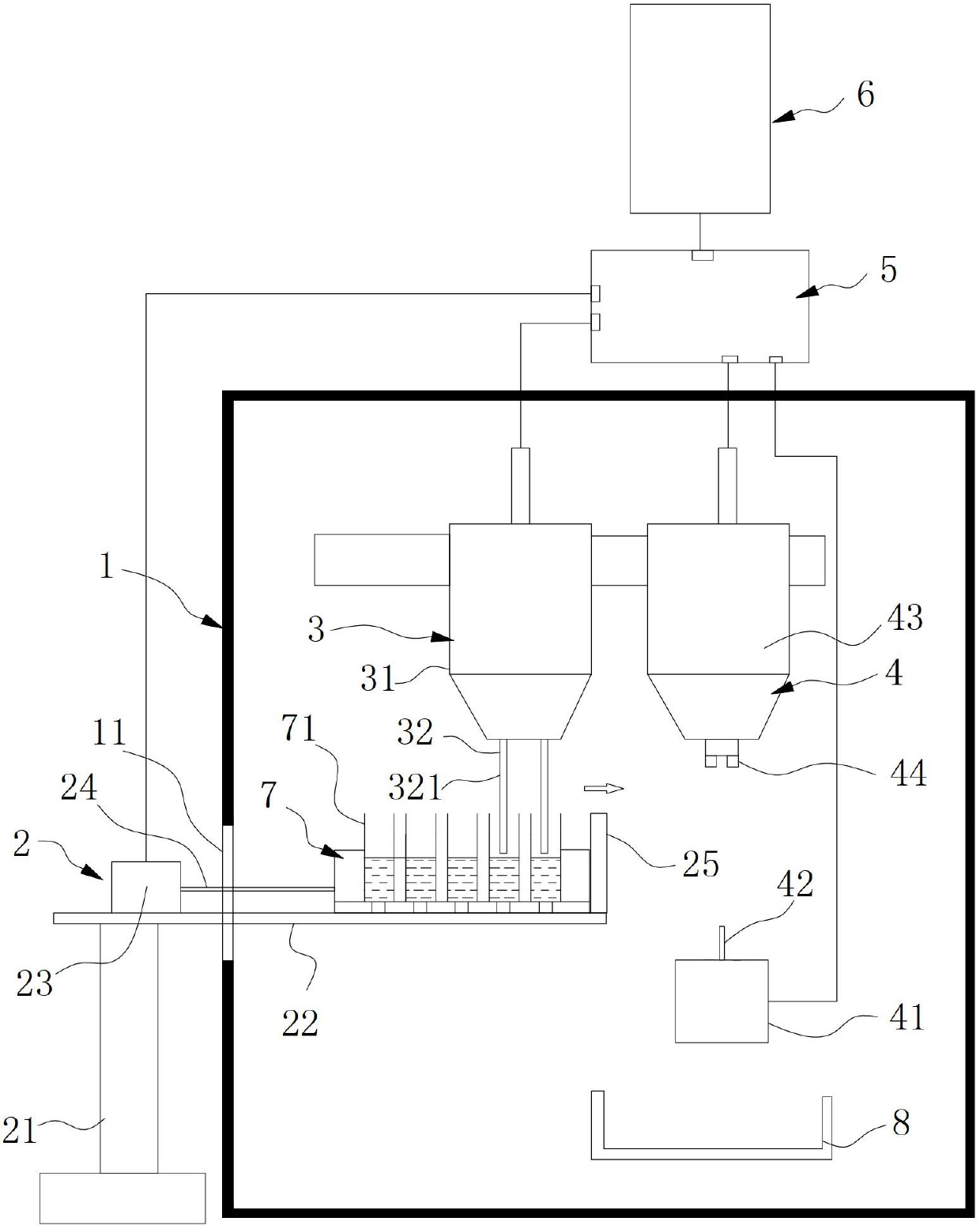

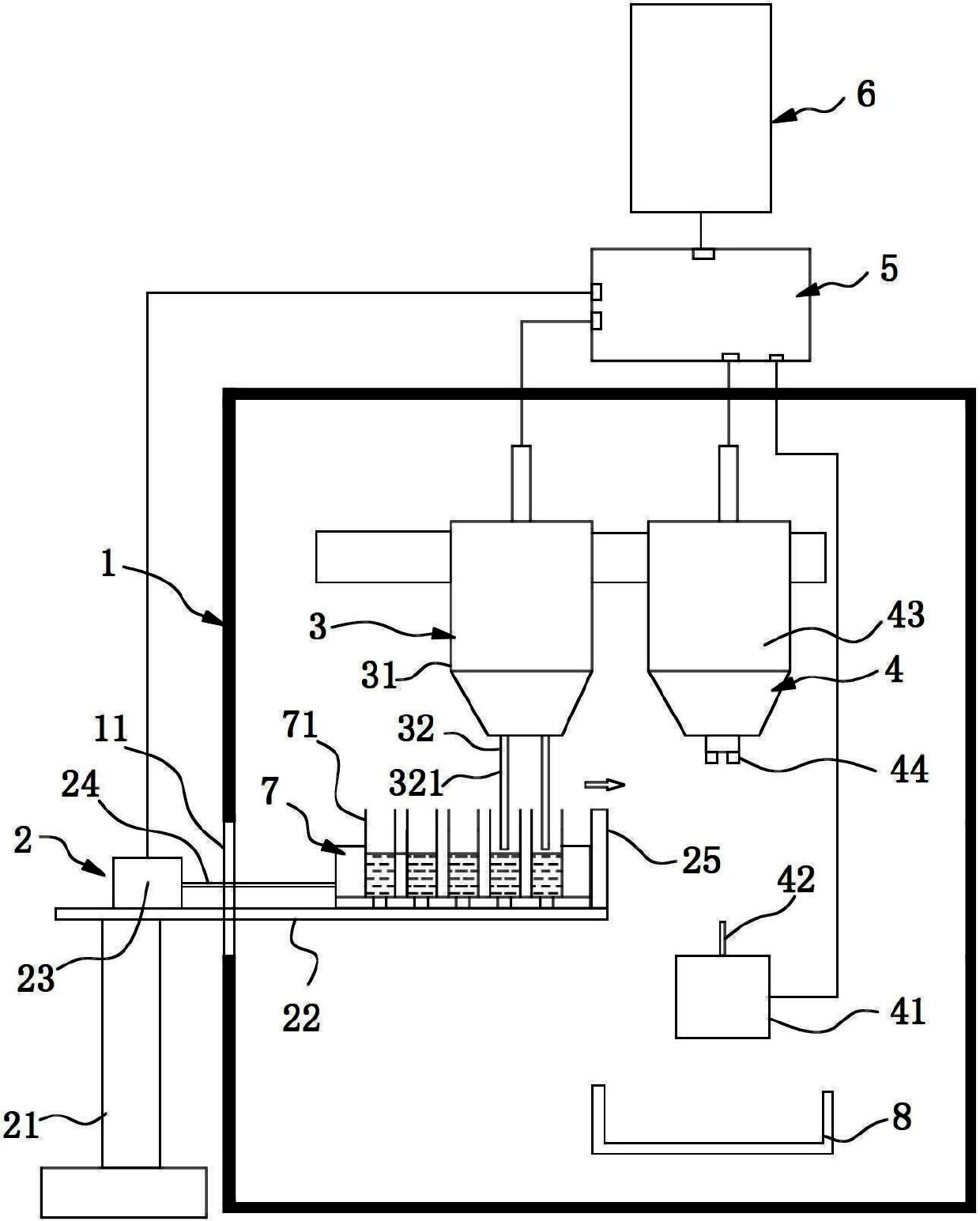

[0029] Please refer to figure 1 , the present invention provides a basic detonator powder column height automatic detection and rejection device, which includes: explosion-proof room 1, automatic mold transmission system 2, powder column height detection system 3, waste product rejection device 4, PLC5 (Programmable Logic Controller, Chinese name : programmable logic controller) and computer 6.

[0030] The explosion-proof room 1 is provided with an explosion-proof window 11 .

[0031] The mold automatic transmission system 2, the mold automatic transmission system 2 has a bracket 21, a supporting plate 22 installed on the bracket 21, a mold pushing cylinder I23, a mold pushing rod I24, a baffle plate 25 and a guide plate (not shown) . One end of the supporting plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com