Automatic detection method of solar silicon chip colors based on machine vision

A technology of machine vision and automatic detection, which is applied in the direction of color measurement devices, optical testing flaws/defects, etc., can solve problems such as unreachable, no substantial progress in detection methods, instability, etc., and achieve the effect of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

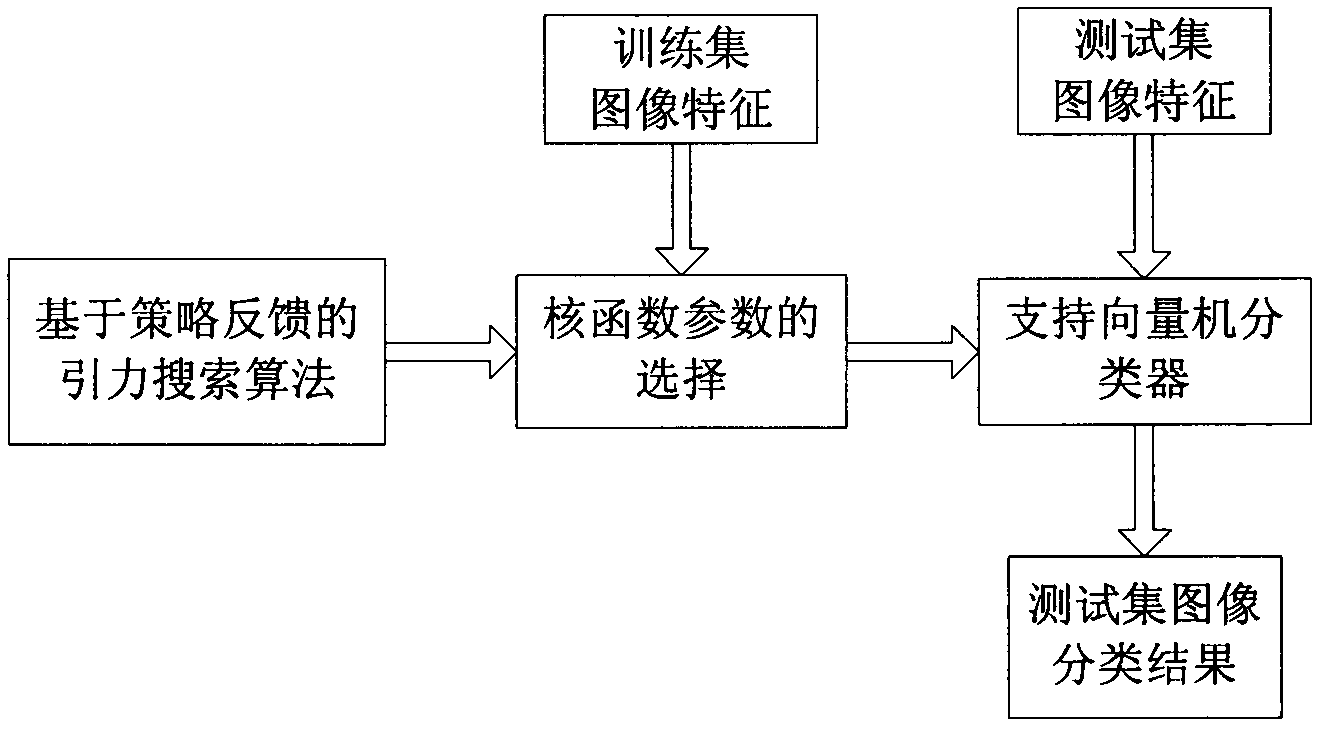

Method used

Image

Examples

Embodiment Construction

[0018] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

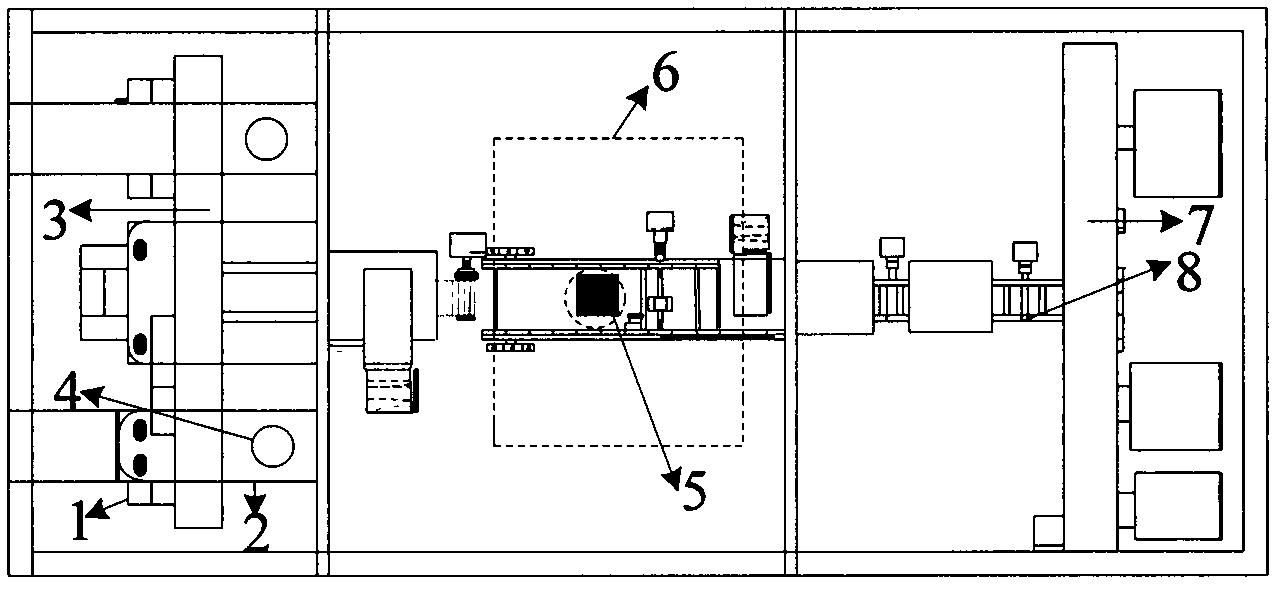

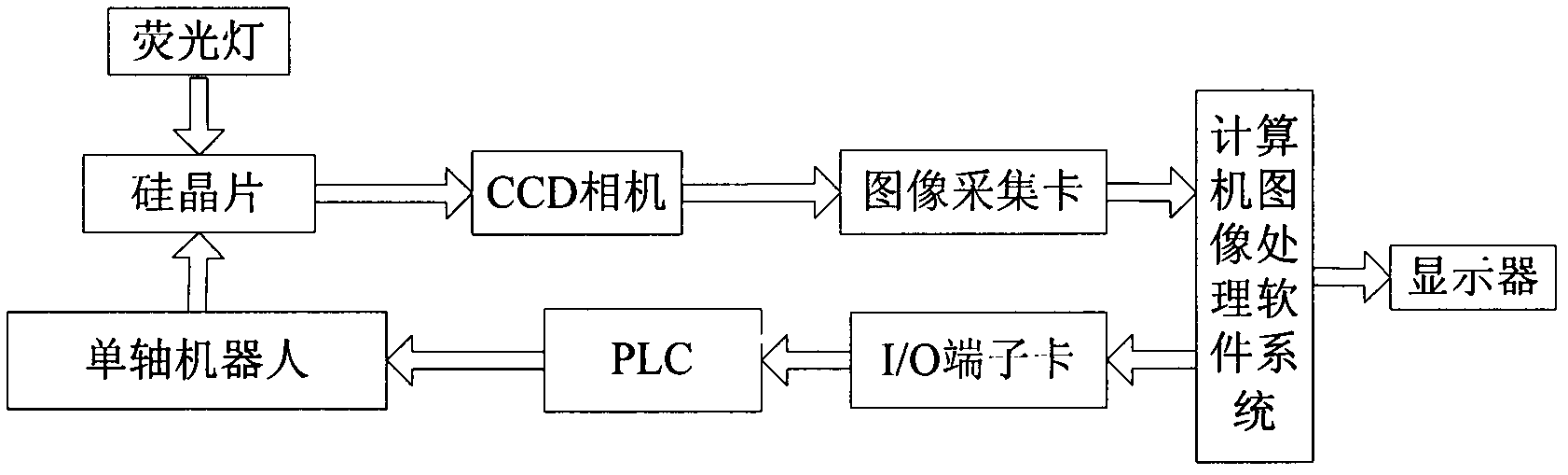

[0019] Automatic detection process: Manually place the material box full of silicon wafers at the designated position; press the device start button; the cylinder pulls the material box to the upper material position; the silicon wafer is lifted by the servo action, and the silicon wafer is moved up; the photoelectric switch is sensed; Lift to the right position; move the module horizontally to the grabbing position; the suction cup works; position; the cylinder moves down; the suction cup stops sucking; the silicon wafer is placed on the transmission belt line; the silicon wafer is translated to the camera inspection station; the camera takes pictures for inspection; the inspection is completed; position; the sorting module, cylinder, and suction cups act to sort silicon wafers into the designated tray; the equipment operates in a cycle. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com