Device for preparing spinning size film and preparation method of spinning size film

A serous film and textile technology, which is applied in the field of instruments for preparing textile serous films and the preparation of textile serous films, can solve the problems of inability to effectively control the preparation time of serous films, easy deterioration of serous film internal stress, easy cracking and the like, To achieve the effects of controllable preparation time, good uniformity of serosa thickness and short time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

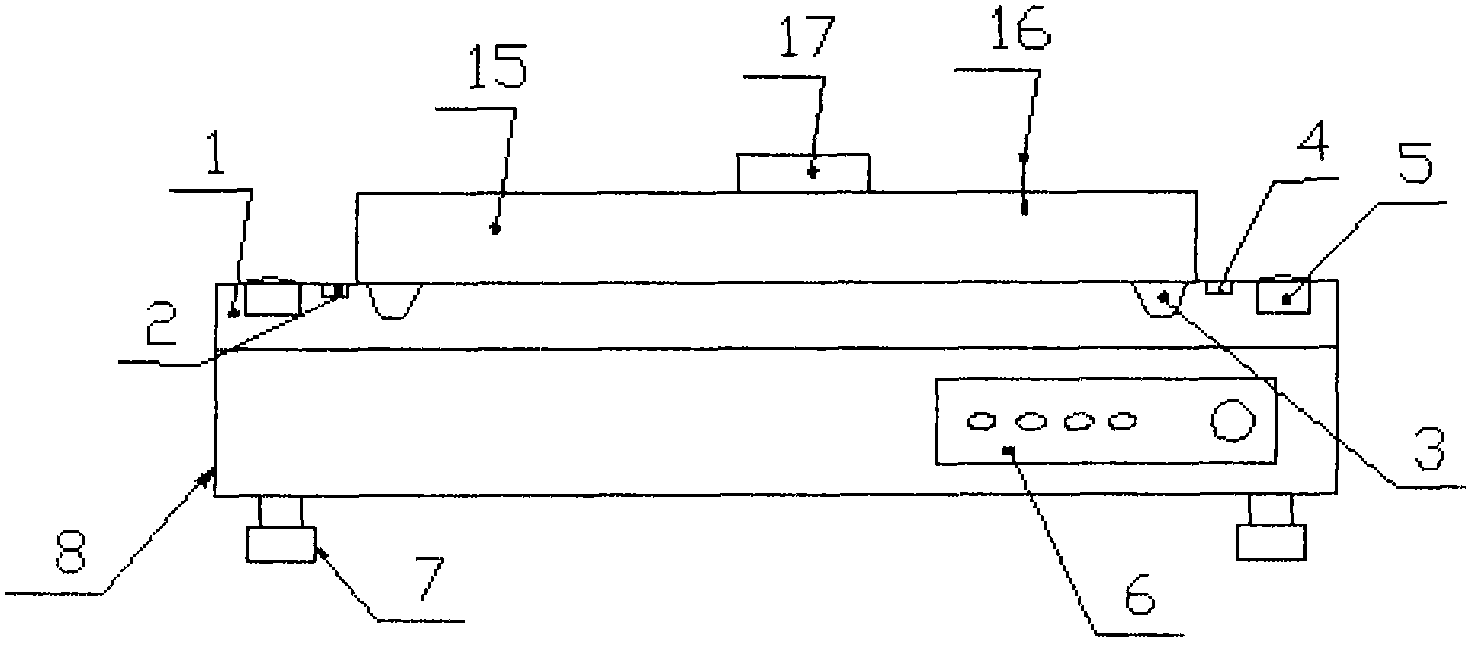

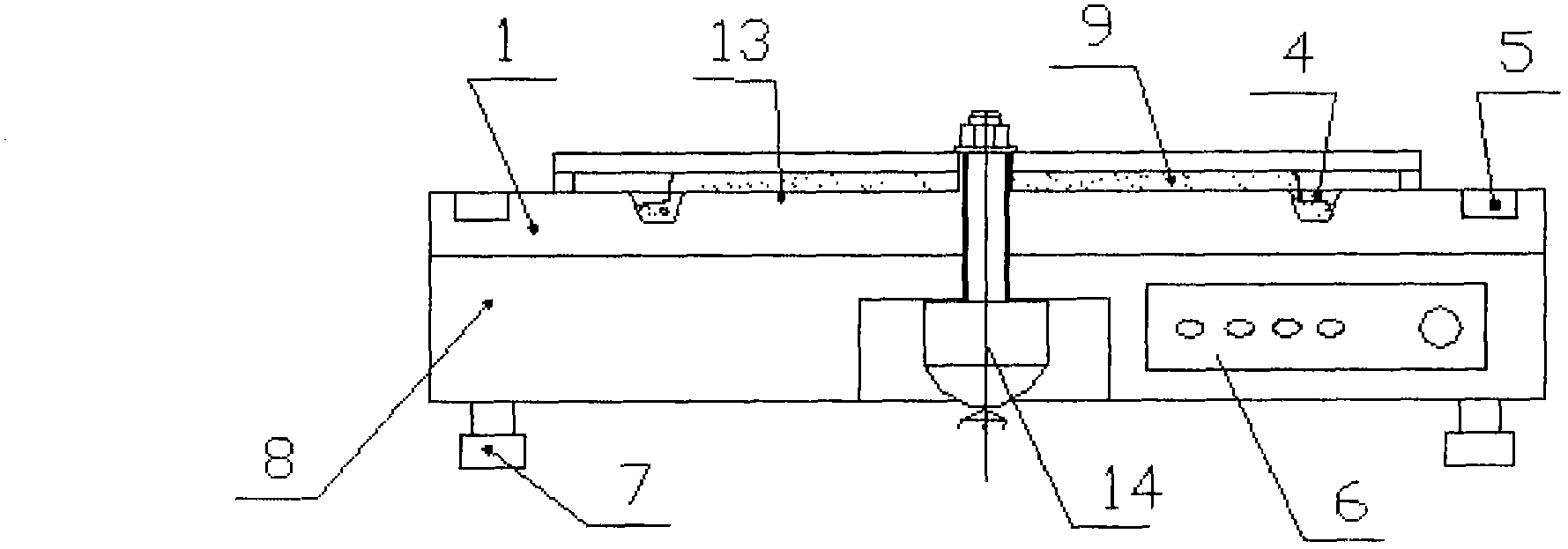

[0060] The preparation method of serous film of the present invention comprises the steps:

[0061] Slurry preparation-slurry spreading-slurry cooking-slurry drying into film-filming.

[0062] Since the thickness of the size film determines the mechanical properties of the size film, such as breaking strength, elongation at break, wear resistance and solubility, the thickness of the prepared size film is generally 0.2-0.5mm. Therefore, when preparing the size film, it is necessary to control the amount of the size liquid or the thickness of the size tank to obtain the required thickness of the size film.

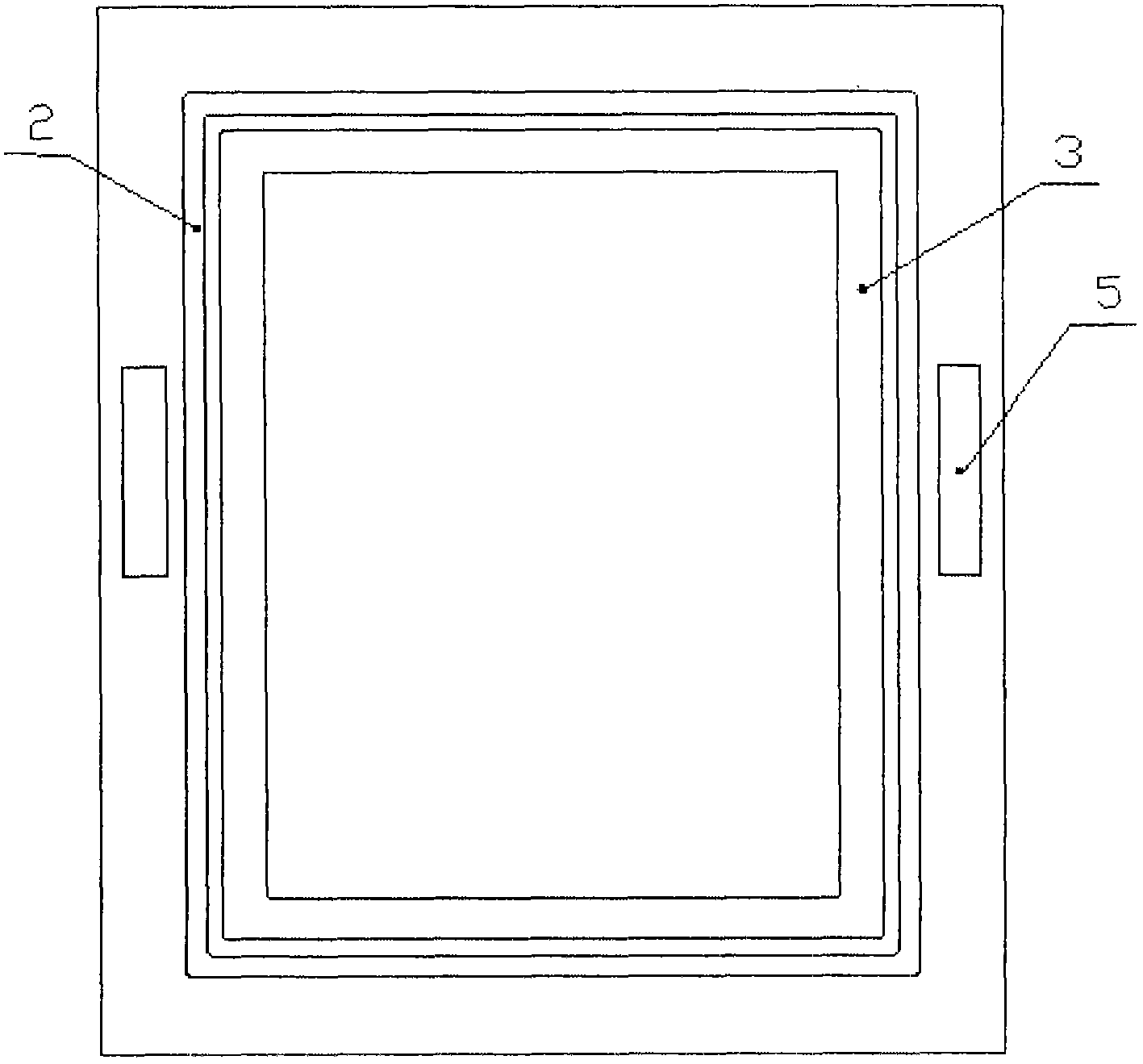

[0063] When using a slurry laying table with a slurry tank to spread slurry, fill the slurry tank with slurry, and the scraping surface of the squeegee moves against the upper surface of the slurry laying table to scrape excess slurry into the slurry overflow tank, here , the depth of the selected size tank should be compatible with the thickness of the prepared size film, ...

Embodiment 1

[0100] The method of the present invention is described in detail by taking the preparation of pure cotton serous film as an example. Use a flat laying table.

[0101] Preparation of slurry: prepare slurry for the components of 60% starch, 30% PVA, and 10% polymethylacrylate by weight percentage, and mix the slurry with water to form a slurry with a solid content of 8% for subsequent use;

[0102] Slurry spread: Calculate the amount of slurry according to formula (2), spread the slurry on the slurry laying table, and scrape the slurry with a scraper;

[0103] Vaporization of slurry water: cover the cover of the slurry laying table, heat the slurry to 130°C with a heating device, and heat at a constant temperature until the slurry is dried and formed into a film, and control the humidity in the cover of the slurry laying table to 65-72%;

[0104] To form a film, cool the size film at room temperature, and open the laying table to cover the film after reaching room temperature. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com