Manufacture method fro transparent electrodes

A manufacturing method and technology for transparent electrodes, which are applied in cable/conductor manufacturing, circuits, electrical components, etc., can solve the problems of reduced transparency of graphene, blocking light, and difficulty in making transparent electrodes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

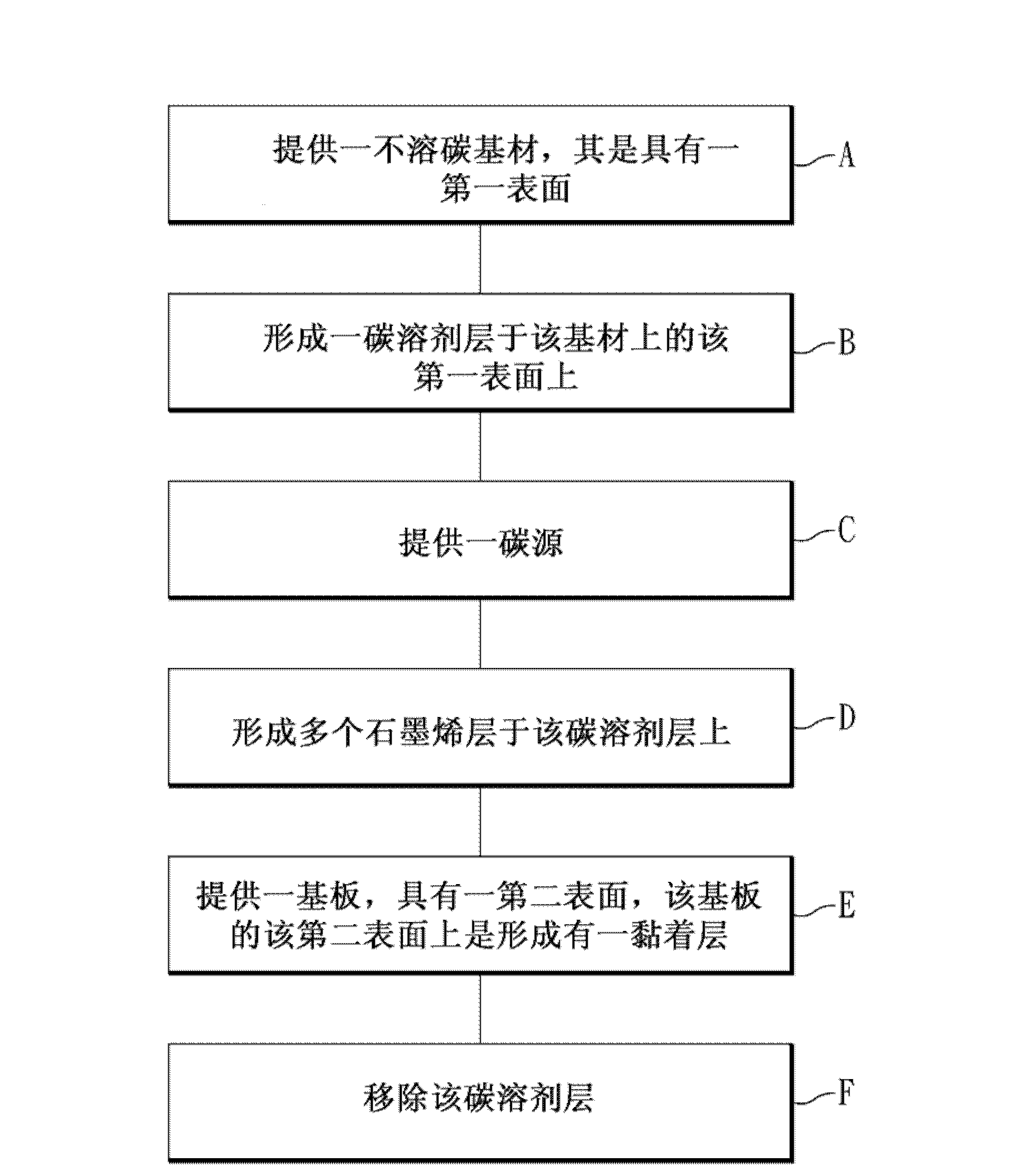

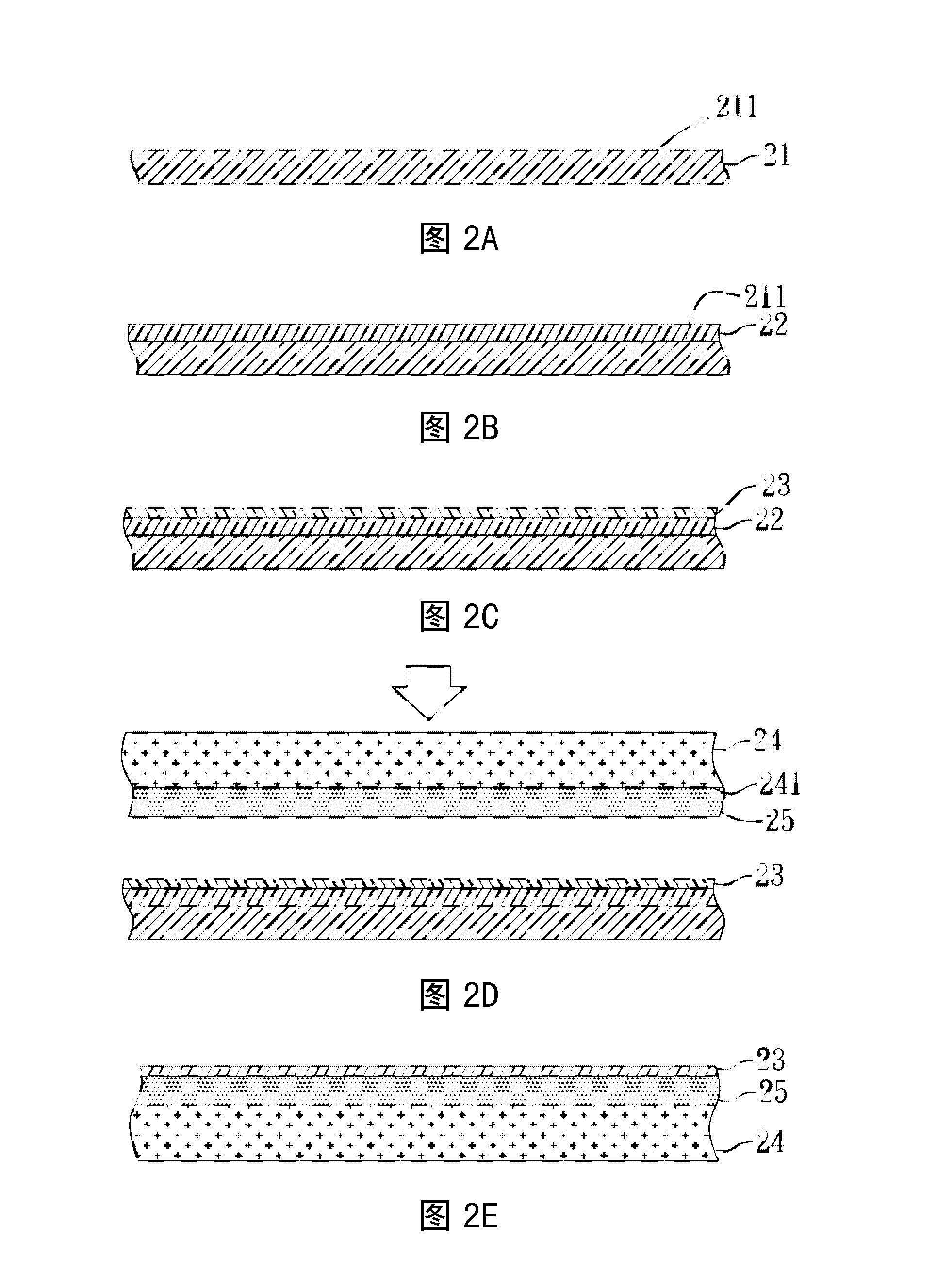

[0040] For a manufacturing method of a transparent electrode of this embodiment, please refer to Figure 2A to Figure 2E . Figure 2A to Figure 2E It is a schematic diagram of a manufacturing method of a transparent electrode of the present invention.

[0041] Please see first Figure 2A , at first provide a substrate 21, is to have a first surface 211, then, please refer to Figure 2B , form a carbon solvent layer 22 on the first surface 211 on the substrate 21, the method of forming the carbon solvent layer 22 is chemical vapor deposition, then, as Figure 2C Therefore, a carbon source (not shown in the figure) is provided, and the carbon source is a carbon-containing gas, and the carbon-containing gas is heated to form a plurality of graphene layers 23 on the carbon solvent layer 22 .

[0042] In the manufacturing method of a transparent electrode of this embodiment, the above-mentioned substrate is not limited to the substrate made of copper used in this embodiment, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com