Environmentally-friendly polyamide resin composition and molded product using same

A polyamide resin, environment-friendly technology, applied in the field of environment-friendly polyamide resin composition, can solve the problems of glass fiber damage, environmental pollution, polycarbonate resin fluidity deterioration, etc., and achieve excellent impact resistance , Environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to 18 and comparative example 1 to 8

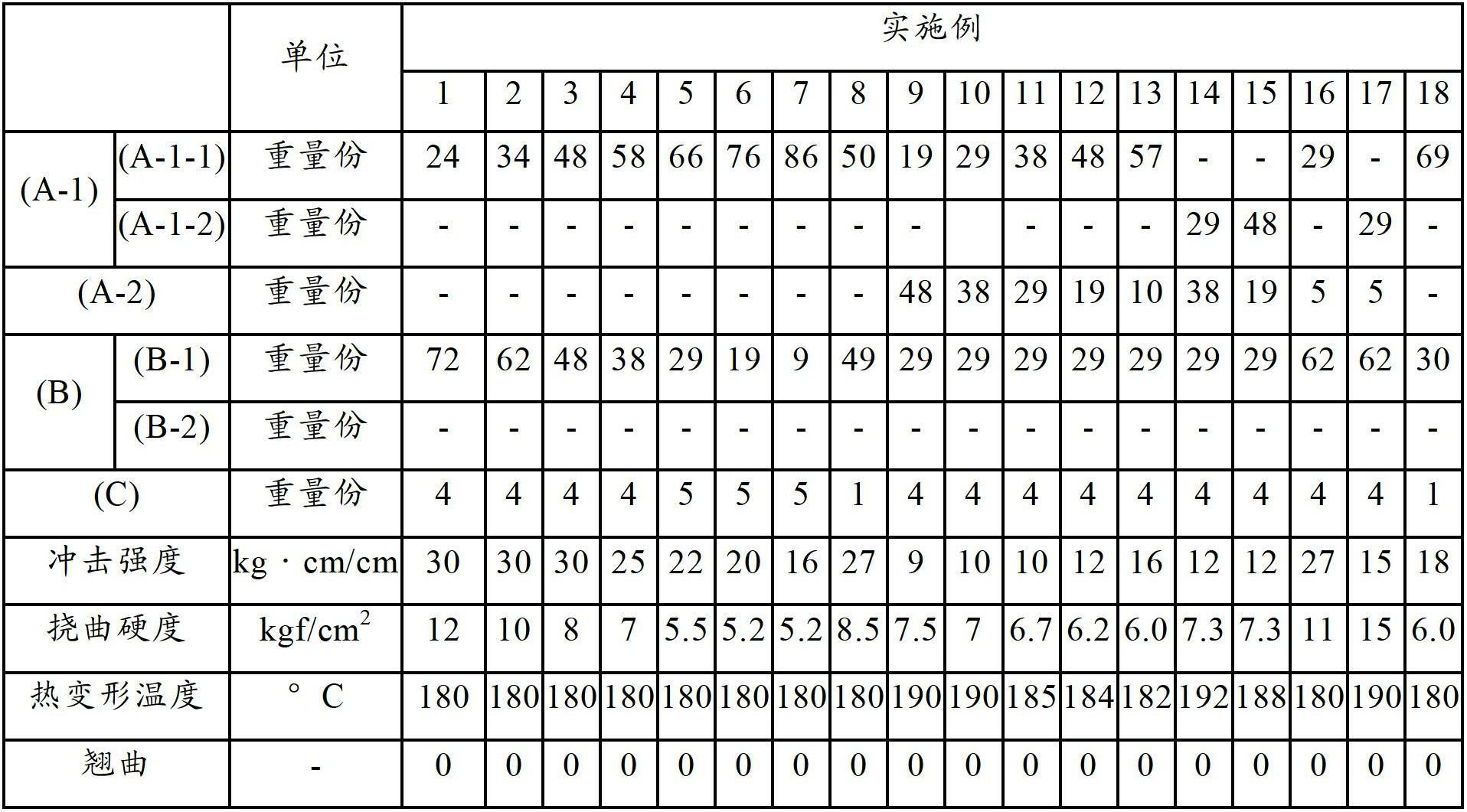

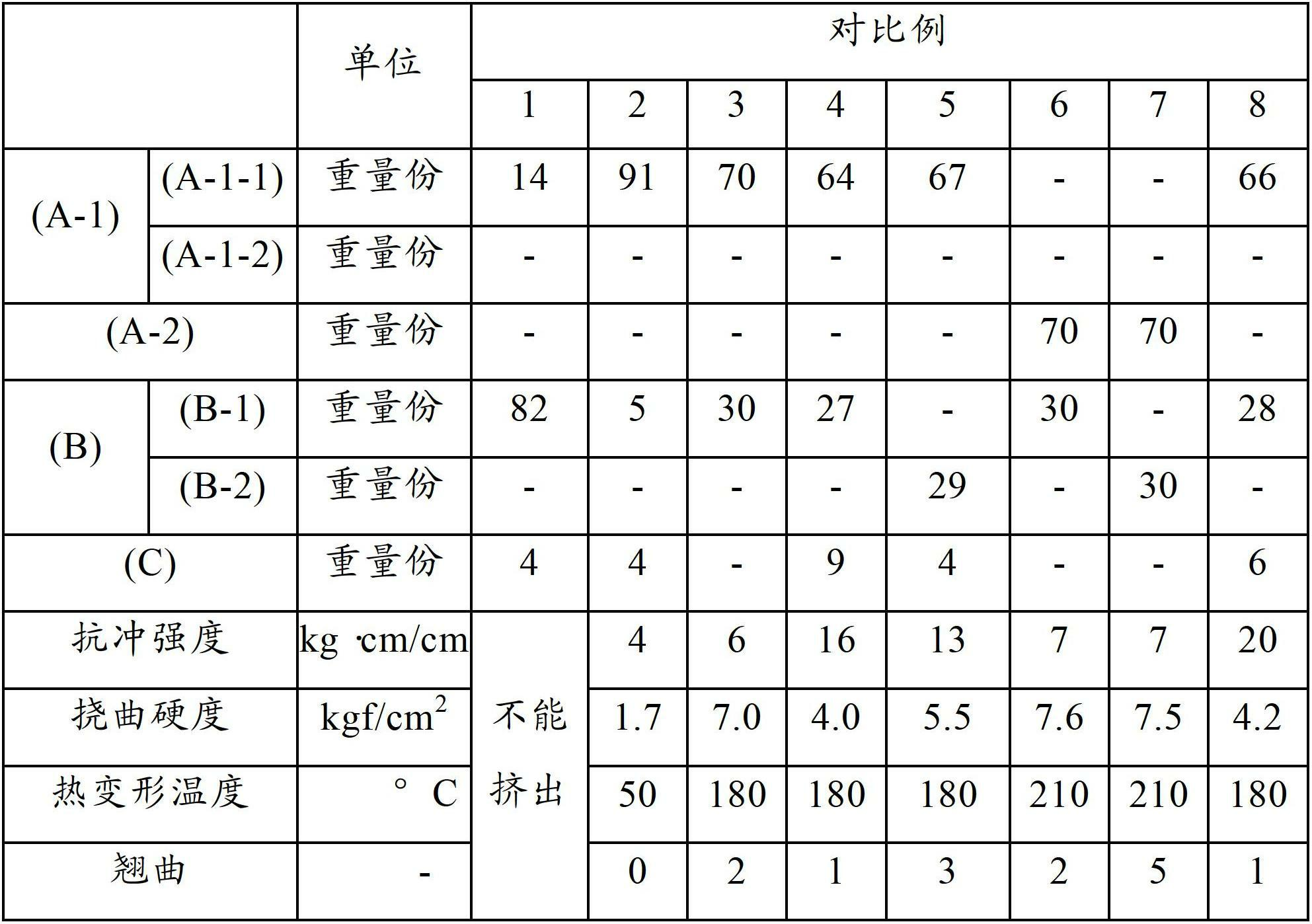

[0076] The above components in the amounts shown in Tables 1 and 2 below were extruded in a common twin-screw extruder and the extruded product was made into pellet form.

experiment example

[0078] By drying the pellets prepared according to Examples 1 to 18 and Comparative Examples 1 to 8 at 100°C for 4 hours, and then using them under the conditions of a plastic temperature of 250 to 270°C and a molding temperature of 60 to 80°C A 10-ounce injection molding machine injection was used to prepare physical samples. The physical properties of these physical samples were measured by the following methods, and the measurement results are shown in Tables 1 and 2 below.

[0079] (1) Impact strength was measured according to ASTM D256 (1 / 8").

[0080] (2) The flexural hardness was measured according to ASTM D790 (2.8 mm / min).

[0081] (3) Heat distortion temperature was measured according to ASTM D648 (18.56kgf).

[0082] (4) Warpage: Inject square samples of 6"X 6"X 1 / 16" film and determine their degree of warpage after ejection.

[0083] Degree of warping: 0 (no warping) → 5 (severe warping)

[0084] (Table 1)

[0085] Based on 100 parts by weight of the (A-1), (A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com