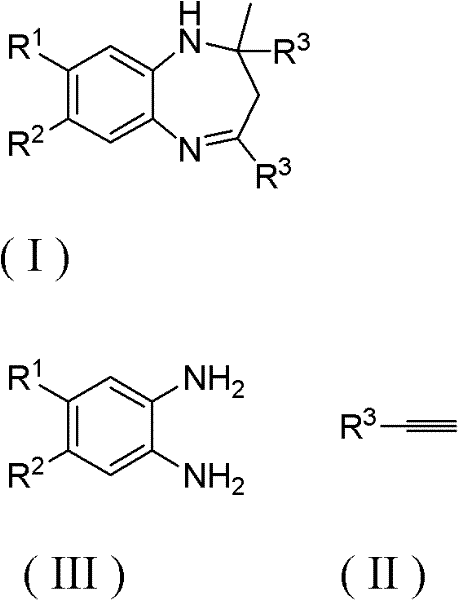

Synthesis method of 1, 5-benzodiazepine derivative

A technology of benzodiazepine and synthesis method, applied in 1 field, can solve problems such as limitation and low atom economy, and achieve the effects of stable storage and access, easy storage and access, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

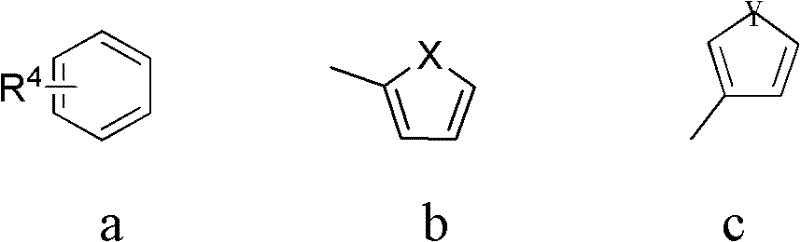

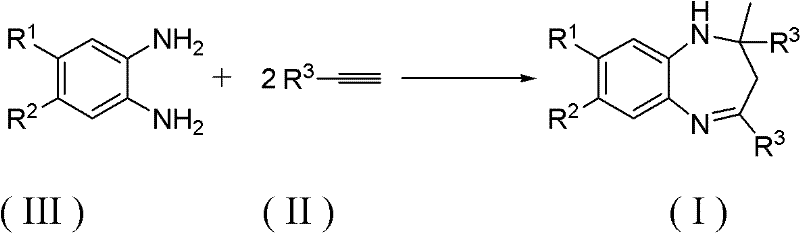

Method used

Image

Examples

Embodiment 1

[0038]

[0039]In a 15ml reactor, sequentially add 21.6mg (0.2mmol) of o-phenylenediamine, 51.1mg (0.5mmol) of phenylacetylene, [bis(trifluoromethanesulfonimide)][2-(dicyclohexylphosphino )] Gold (I) 8.3 mg (0.01 mmol) and chloroform (2 mL). Then, the mixture was stirred and reacted at 60° C. for 6 hours. TLC (developing agent ratio: petroleum ether to ethyl acetate volume ratio 10:1) detection After the reaction is completed, 100-200 mesh silica gel (0.5g) is added to the reaction mother liquor, the solvent is removed under reduced pressure, and the obtained residue is directly added to the silica gel column. , separated by column chromatography (eluent ratio: petroleum ether to ethyl acetate volume ratio 10:1), collected the eluate and evaporated the solvent to obtain a yellow solid 2-methyl-2,4-diphenyl Dihydro-2,3-dihydro-1H-1,5-benzodiazepine 58.1 mg (93% yield). Product characterization: Yellow solid; mp 150-152°C (lit.mp 150-152°C); IR (KBr): v=3336, 3057, 2971, 16...

Embodiment 2

[0041]

[0042] In a 15ml reactor, sequentially add 21.6mg (0.2mmol) of o-phenylenediamine, 58.1mg (0.5mmol) of p-methylphenylacetylene, [bis(trifluoromethanesulfonimide)][2-(bicyclic Hexylphosphino)] gold (I) 8.3 mg (0.01 mmol) and chloroform (2 mL). Then, the mixture was stirred and reacted at 60° C. for 6 hours. TLC (developing agent ratio: petroleum ether to ethyl acetate volume ratio 10:1) detection After the reaction is completed, 100-200 mesh silica gel (1.0 g) is added to the reaction mother liquor, the solvent is removed under reduced pressure, and the obtained residue is directly added to the silica gel column. , separated by column chromatography (eluent ratio: petroleum ether to ethyl acetate volume ratio 10:1), collected the eluate and evaporated the solvent to obtain a yellow solid 2-methyl-2,4-xylene Dihydro-2,3-dihydro-1H-1,5-benzodiazepine 62.6 mg (92% yield). Product characterization: Yellow solid; mp 99-100°C (lit.mp98-99°C); IR (KBr): v=3336, 2969, 292...

Embodiment 3

[0044]

[0045] In a 15ml reactor, 21.6mg (0.2mmol) of o-phenylenediamine, 66.1mg (0.5mmol) of p-methoxyphenylacetylene, [bis(trifluoromethanesulfonimide)][2-(di Cyclohexylphosphino)] gold (I) 8.3 mg (0.01 mmol) and chloroform (2 mL). Then, the mixture was stirred and reacted at 60° C. for 6 hours. TLC (developing agent ratio: petroleum ether to ethyl acetate volume ratio 10:1) detection After the reaction is completed, 100-200 mesh silica gel (1.0 g) is added to the reaction mother liquor, the solvent is removed under reduced pressure, and the obtained residue is directly added to the silica gel column. , separated by column chromatography (eluent ratio: petroleum ether to ethyl acetate volume ratio 10:1), collected the eluate and evaporated the solvent to obtain a yellow solid 2-methyl-2,4-dimethyl Oxyphenyl-2,3-dihydro-1H-1,5-benzodiazepine 60.3 mg (81% yield). Product characterization: Yellow solid; mp 118-120°C (lit.mp 114-116°C); IR (KBr): v=3338, 3052, 2963, 1604, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com