Multifunctional engineering machinery based on excavator platform

A technology for construction machinery and excavators, applied in mechanically driven excavators/dredgers, drilling equipment, drilling equipment and methods, etc., can solve the problem of insufficient drilling depth of rotary drilling rigs, shortening the service life, and affecting the operator's sight. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

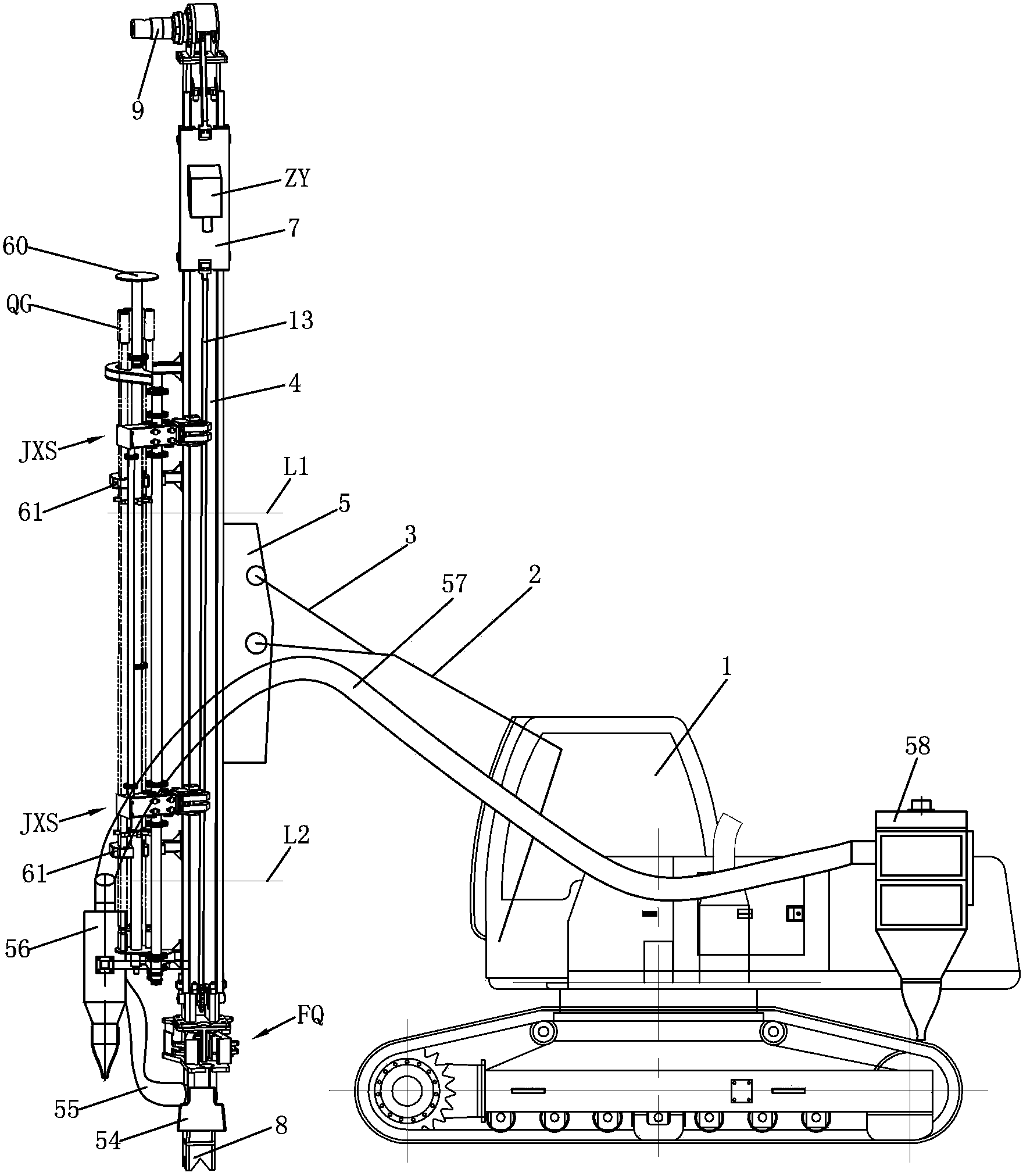

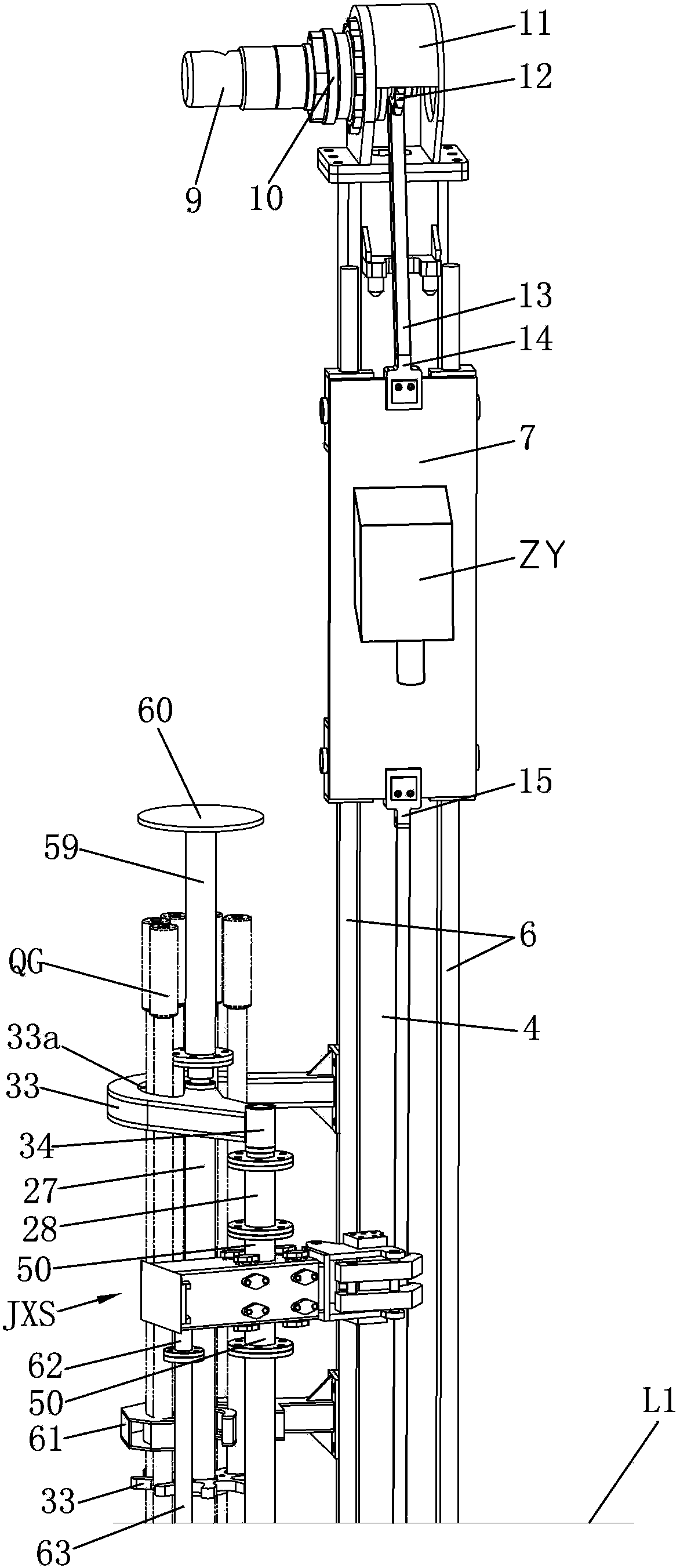

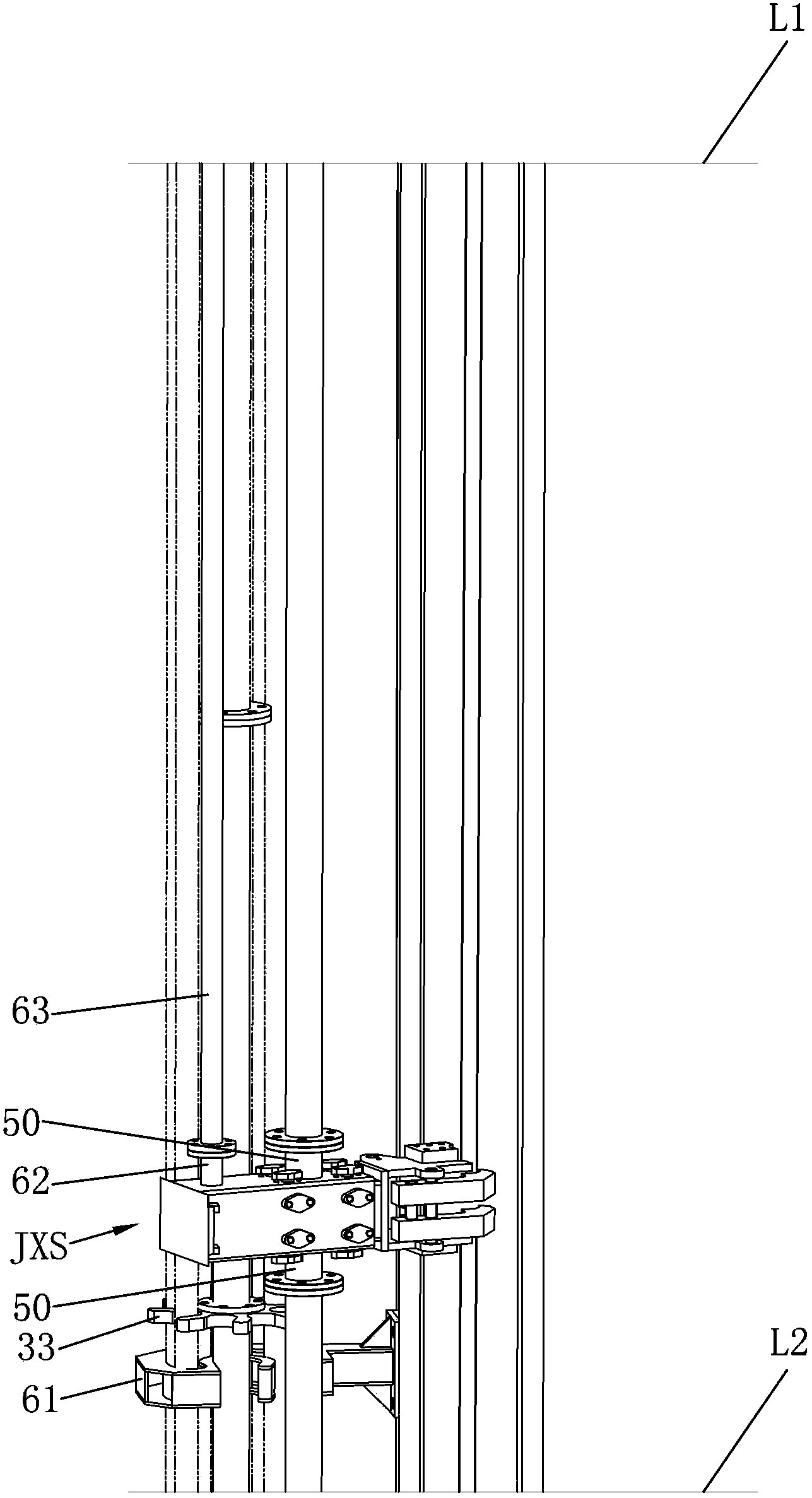

[0048] Such as Figure 1-8 As described, the present invention consists of an excavator 1, an operating arm 2, an executive cylinder 3, a drill frame 4, a connecting plate 5, a guide rail 6, a slide plate 7, a support frame 8, a power source 9, a connecting plate 10, a power source mounting seat 11, and a drive Sprocket 12, chain section 13, upper chain clamp 14, lower chain clamp 15, driven sprocket 16, driven shaft 17, socket 18, screw rod 19, positioning block 20, adjusting nut 21, half body 22, hinge shaft 23. Upper connecting plate 24, lower connecting plate 25, first oil cylinder 26, connecting shaft 27, adapter shaft 28, drill rod top bracket 29, tray 30, bushing 31, base 32, separation disc 33, upper shaft sleeve 34 , lower bushing 35, connecting lug 36, second oil cylinder 37, outer sleeve 38, mounting plate 39, inner sleeve 40, closing plate 41, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com