Integrated gasification combined cycle system with vapor absorption chilling

一种循环系统、整体气化的技术,应用在整体气化联合循环系统领域,能够解决低总体功率设备净输出和效率、成本高昂、不切实际等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

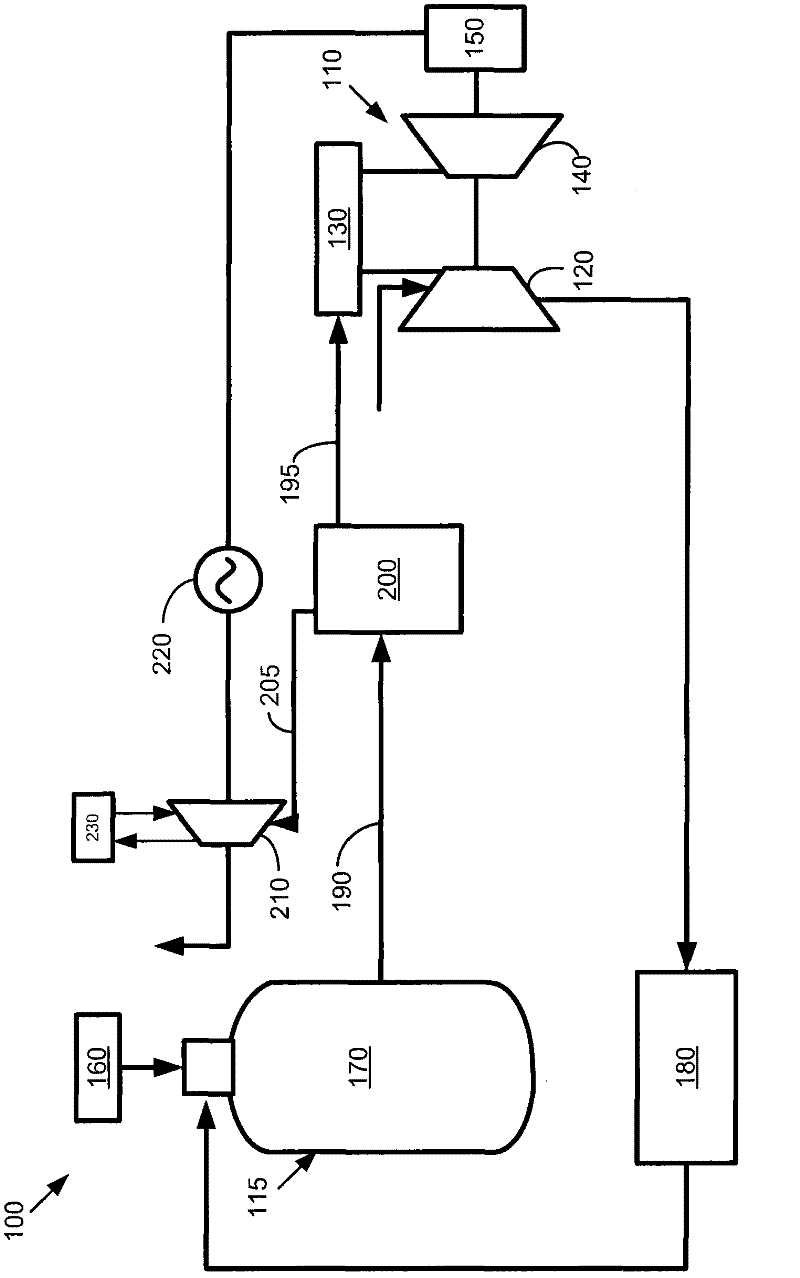

[0061] Referring now to the drawings, like numerals in the drawings represent like elements throughout the various views.

[0062] pieces, figure 1 A schematic diagram of a known integrated gasification combined cycle system 100 is shown. For simplicity, only those elements relevant to the subject matter described herein are shown. The overall integrated gasification combined cycle system 100 may have many other configurations and use many other types of equipment.

[0063] Integrated gasification combined cycle system 100 may include one or more gas turbine engines 110 . As is known, gas turbine engine 110 may include compressor 120 for compressing an incoming airflow. Compressor 120 delivers a stream of compressed air to combustor 130 . Combustor 130 mixes the compressed air flow with the compressed fuel flow and ignites the mixture. Although only a single combustor 130 is shown, the gas turbine engine 110 may include any number of combustors 130 . In turn, the hot com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com