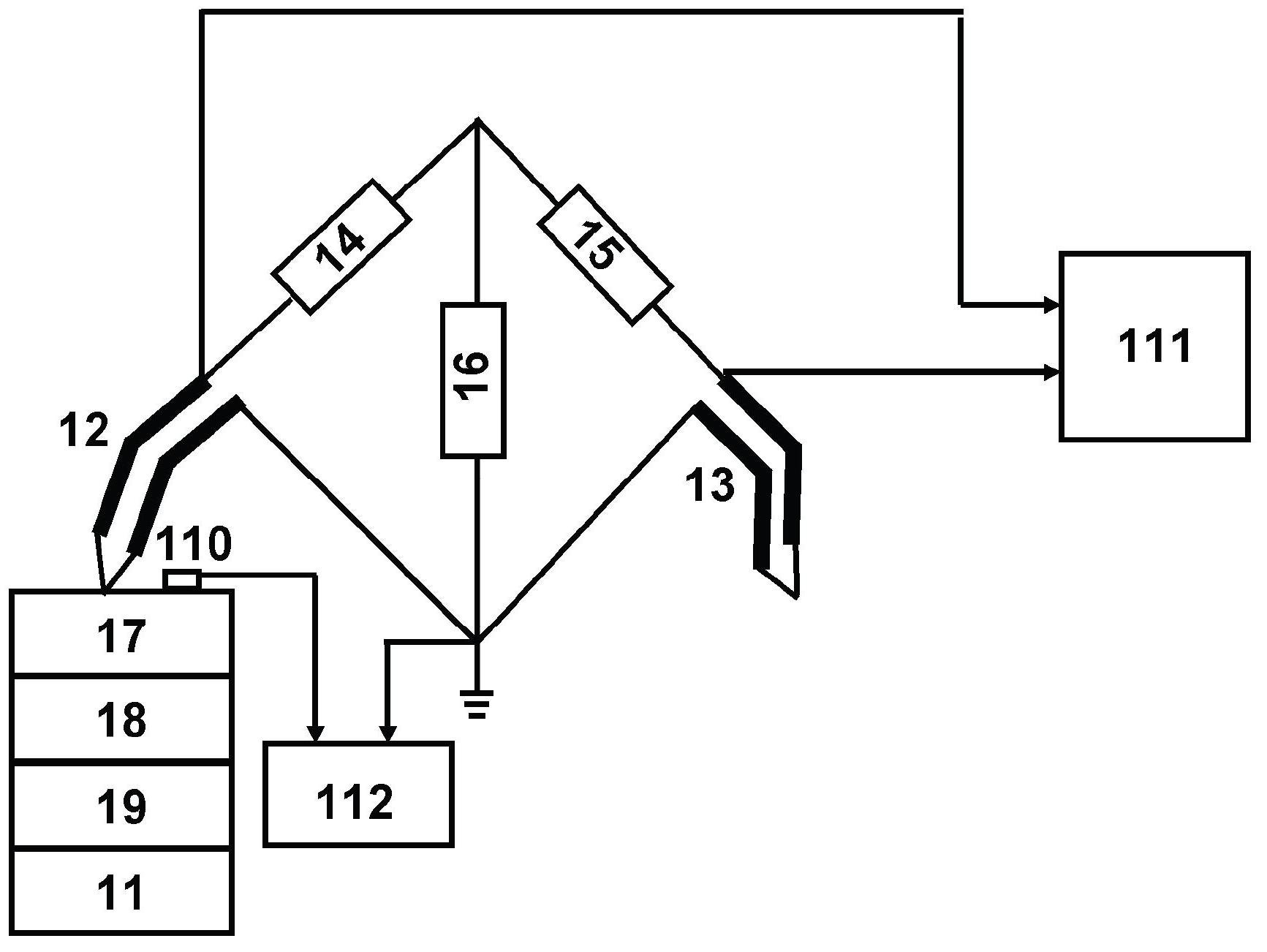

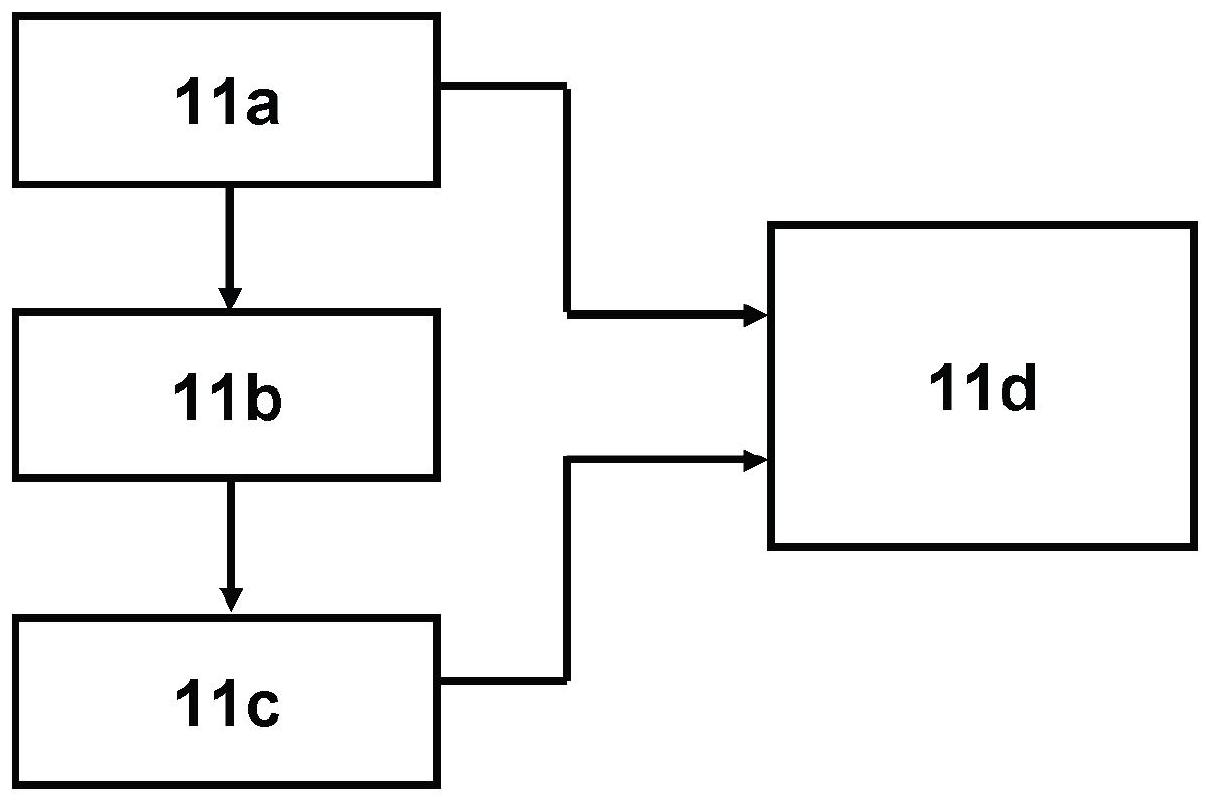

Nano-thermoelectric multi-parameter in-situ quantitative characterization device based on atomic force microscope

An atomic force microscope and in-situ quantitative technology, which is applied in measuring devices, nanotechnology, scanning probe microscopy, etc., can solve the problem that the test method is static, cannot reflect the dynamic performance change state of thermoelectric materials, and cannot achieve real-time and synchronous detection And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The nano-thermoelectric multi-parameter in-situ quantitative characterization technology established in this application was used to test the micro-region thermal conductivity of the Bi-Sb-Te thermoelectric thin film, and Figure 6 shows the test results. Among them, Figure 6(a) is the AFM image of the surface topography of the sample, and Figure 6(b) is the micro-area triple frequency of the three measurement points obtained in situ in the corresponding area of the sample by the established nano-thermoelectric multi-parameter in-situ quantitative characterization technique The relationship between the thermal conductance signal and the logarithm of the excitation frequency. According to the near-field thermal imaging conditions, the microscopic thermal conductivity can be calculated as λ=1.668W / (m·K). Since the macroscopic thermal conductivity test technology of thin film has not been satisfactorily resolved so far, it is impossible to compare the thermal conductivity...

Embodiment 2

[0050]The micro-region Seebeck coefficient of the Bi-Sb-Te thermoelectric thin film was tested by applying the nano-thermoelectric multi-parameter in-situ quantitative characterization technology established in this application. Figure 7 shows the test results. It must be pointed out that the results are consistent with those in Figure 8 Results obtained simultaneously in situ during thermoelectric characterization of micro-domains. Figure 7(a) shows the test results of the probe voltage under different excitation voltages, and Figure 7(b) shows the test results of the Seebeck voltage under different excitation voltages. According to the specific thermistor characteristics of the thermal probe and the balance characteristics of the thermoelectric circuit bridge, the temperature of the probe under different excitation voltages can be calculated from Figure 7(a), which corresponds to the temperature of the micro-region of the thermoelectric film. Thus, according to the calculate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com