Particle capture unit, method for manufacturing the same, and substrate processing apparatus

A substrate processing device and particle capture technology, applied in the direction of reacting gas medium and gas medium, manufacturing tools, chemical instruments and methods, etc., can solve the damage of TMP rotor blades, reduce exhaust efficiency, and reduce exhaust efficiency and other problems, to achieve reliable capture, prevent foreign matter from entering the treatment chamber, and prevent damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

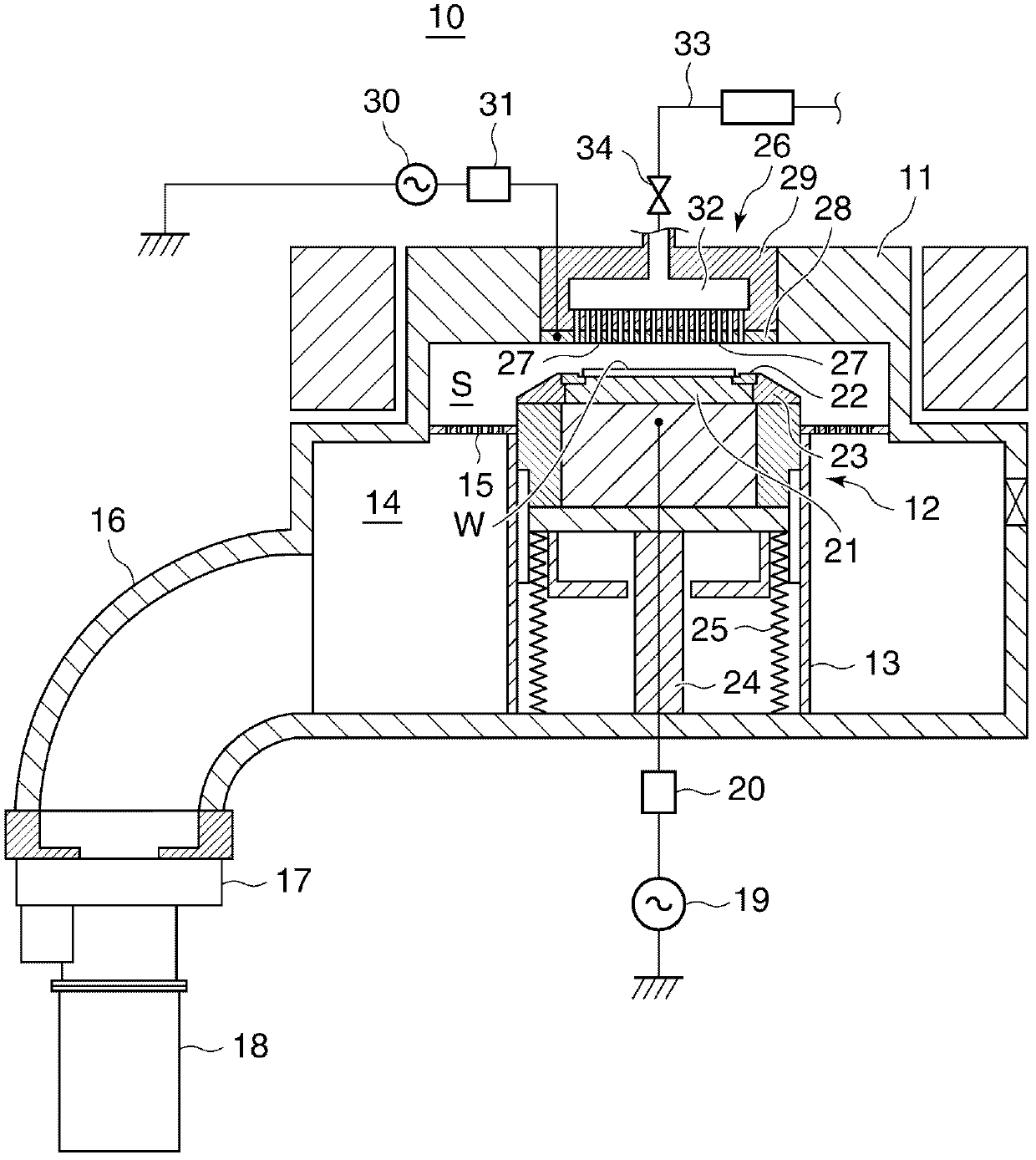

[0034] figure 1 It is a cross-sectional view schematically showing the structure of a substrate processing apparatus to which the particle trap unit according to the embodiment of the present invention is applied.

[0035] exist figure 1 Among them, as a substrate processing apparatus 10 configured as an etching processing apparatus for performing reactive ion etching (Reactive Ion Etching) (hereinafter referred to as “RIE”) on a semiconductor wafer (hereinafter, simply referred to as “wafer”) W, it is equipped with metal, The chamber 11 (processing chamber) is formed of, for example, aluminum or stainless steel and has a shape in which two large and small cylinders overlap.

[0036] Arranged in the chamber 11 are: a lower electrode 12 serving as a wafer stage on which a wafer W is placed and ascending and descending in the chamber 11 together with the placed wafer W;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com