Improved LED chip having current blocking layer and preparation method thereof

A current blocking layer and LED chip technology, applied in circuits, electrical components, semiconductor devices, etc., can solve the problems of uneven current diffusion, low light extraction efficiency, and high heat of LED chips, so as to improve light extraction efficiency, increase reflection probability, The effect of meeting mass production requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

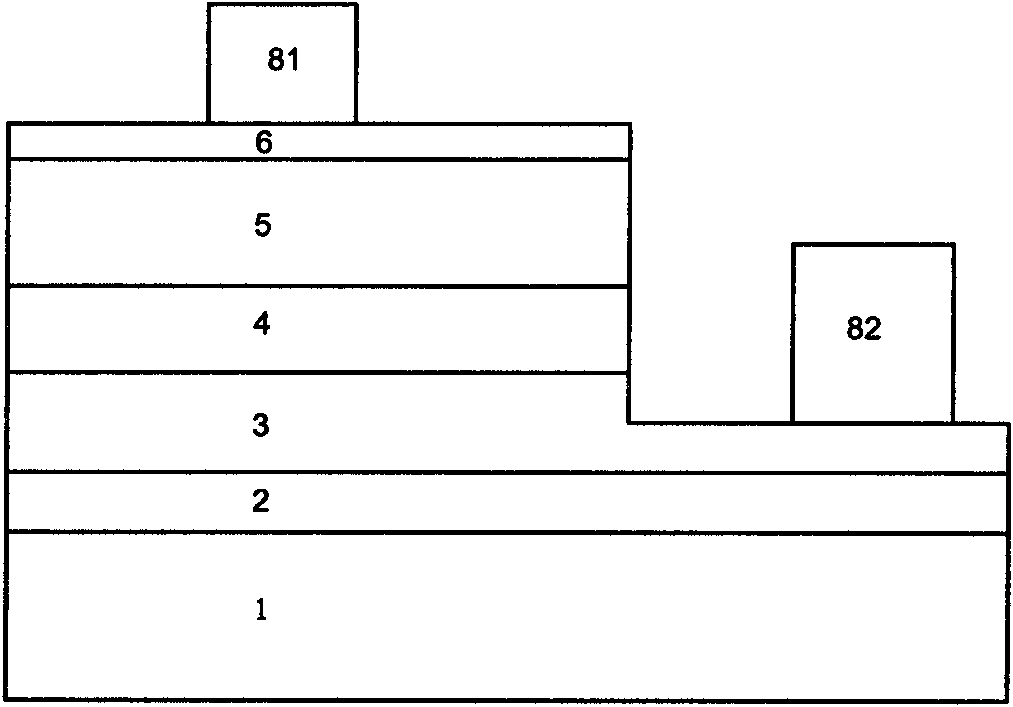

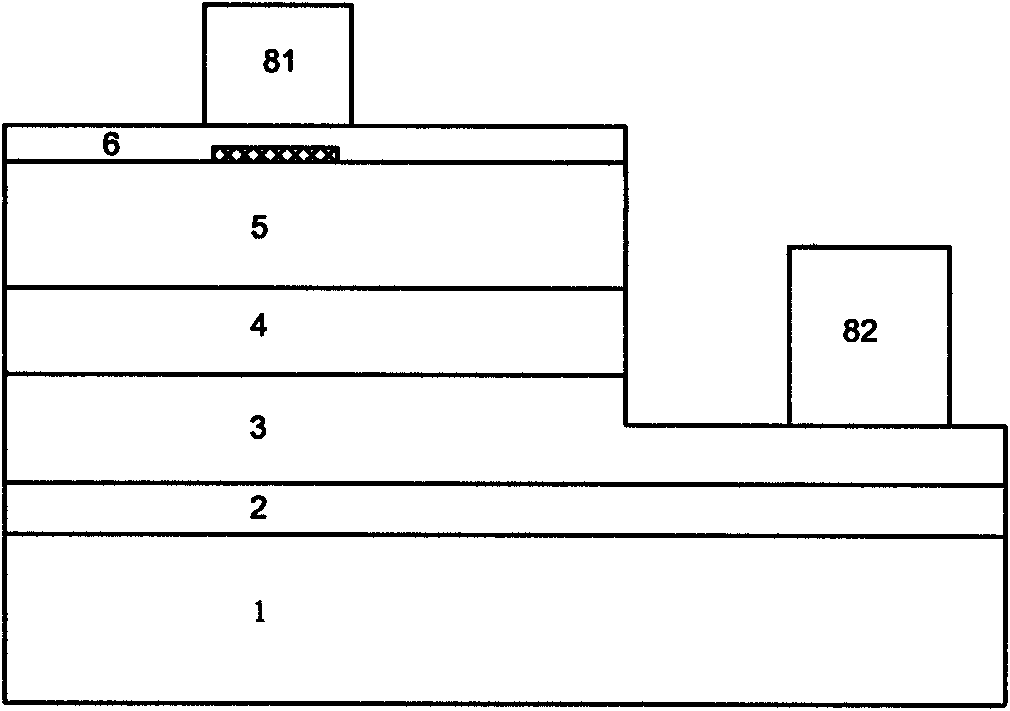

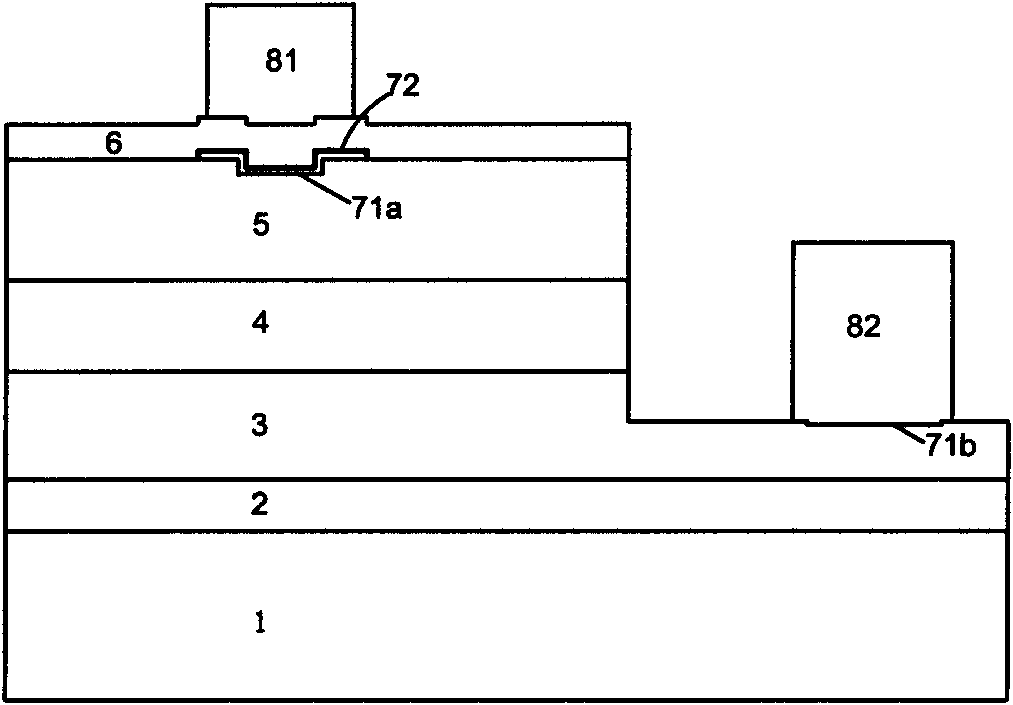

[0031] See image 3 , An improved light-emitting diode chip with a current blocking layer includes: an N-type semiconductor layer 3, a light-emitting layer 4 formed on the N-type semiconductor layer, a P-type semiconductor layer 5 formed on the light-emitting layer, and a P-type semiconductor layer. The transparent conductive layer 6 on the transparent conductive layer, the P electrode 81 formed on the transparent conductive layer, and the N electrode 82 formed on the N-type semiconductor layer. A smooth surface is formed on the P-type semiconductor layer directly below the P-type electrode. A trench 71a, and a current blocking layer 72 is formed on the first trench 71a.

[0032] In actual production, the LED chip further includes a substrate 1 and a buffer layer 2 formed on the substrate as required. The N-type semiconductor layer 3, the light-emitting layer 4, and the P-type semiconductor layer 5 are sequentially formed on the buffer layer 2. on. The addition of the buffer lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com