A heat-reflecting-barrier composite energy-saving coating material and its preparation method

A coating material and composite technology, applied in the field of coatings, can solve the problems of coating heat insulation effect, reflection effect and conventional performance limitations, improper selection of pigments and fillers and addition amount, poor convection and radiation heat transfer effects, etc., to achieve Improved pollution resistance index, improved appearance effect, good heat insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

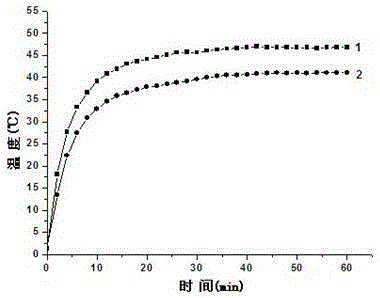

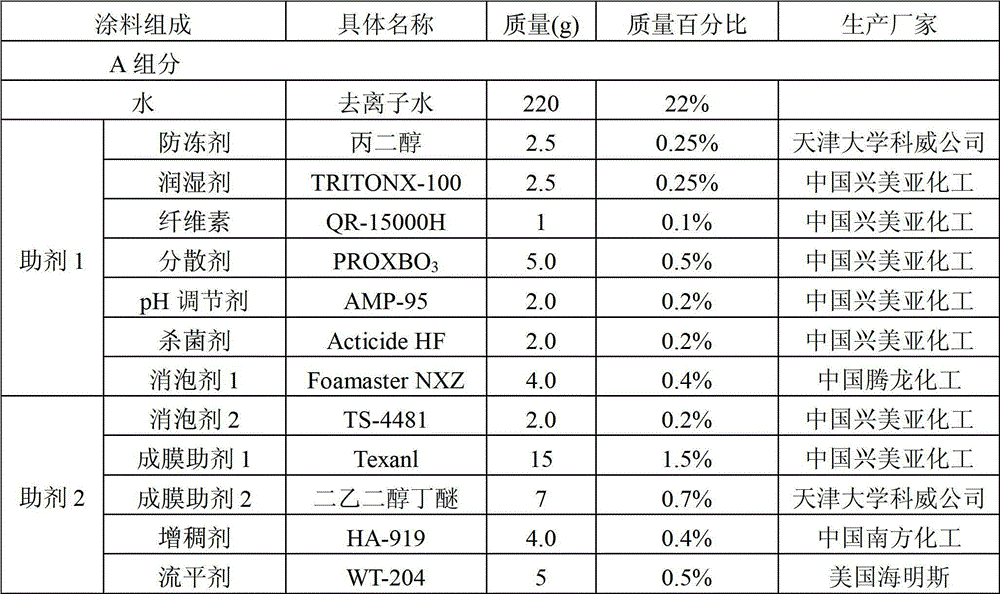

[0053] The embodiment of the present invention provides a method for preparing a heat reflection-barrier composite energy-saving coating material, which has high solar reflectance and heat insulation effect, and its formula is shown in Table 1:

[0054] Table 1 Embodiment 1 formula table

[0055]

[0056]

[0057] The specific preparation method of the composite energy-saving coating material is as follows:

[0058] 1. Modification of ingredients

[0059] ⑴Mix the mineral materials sepiolite, attapulgite and barite at a ratio of 2:2:1, and then dynamically dry them in a drying equipment at 125°C for 3 hours. After removing moisture, weigh them, and add 2.5% by mass Silane coupling agent ZH-1304, mix and react for 2 hours, wash repeatedly with absolute ethanol for 3 times, then dry, and use LNJ series jet milling classifier jet milling for 60 minutes to obtain nanometer ultrafine surface hydrophobic modified minerals with an average particle size of 60nm Material;

[0...

Embodiment 2

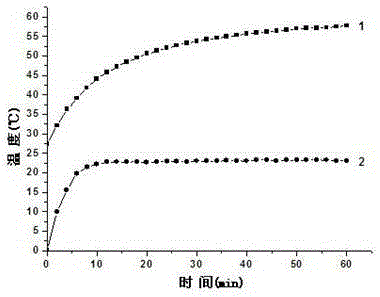

[0074] The embodiment of the present invention provides a method for preparing a heat reflection-barrier composite energy-saving coating material, which has high solar reflectance and heat insulation effect, and its formula is shown in Table 2:

[0075] Table 2 Example 2 formula table

[0076]

[0077]

[0078] The specific preparation method of the composite energy-saving coating material is as follows:

[0079] 1. Modification of ingredients

[0080] ⑴Mix the mineral material sepiolite, barite and mica powder in a ratio of 2:1:1, and then dynamically dry it in a drying equipment at 130°C for 2 hours. After removing water, weigh it, and add 2.0% by mass of silane Coupling agent KH570 and 1% titanate coupling agent NDZ-131, mixed and reacted for 2 hours, washed repeatedly with absolute ethanol for 3 times, dried, and pulverized by a high-energy ball mill for 50 minutes to obtain a nanometer ultra-fine surface with an average particle size of 80nm Hydrophobically modifi...

Embodiment 3

[0094] The embodiment of the present invention provides a preparation method of a heat reflection-barrier composite energy-saving coating material, which has a high solar reflectance and heat insulation effect, and its formula is shown in Table 3:

[0095] Table 3 Example 3 formula table

[0096]

[0097]

[0098] The specific preparation method of the composite energy-saving coating material is as follows:

[0099] 1. Modification of ingredients

[0100] ⑴Mix the mineral materials sepiolite, barite and calcium carbonate at a ratio of 2:1:1, and then dynamically dry them in a drying equipment at 140°C for 1.5 hours. After removing moisture, weigh them, and add 4.0% titanium by mass Ester coupling agent NDZ-401, mix and react for 3 hours, wash repeatedly with absolute ethanol for 3 times, then dry, and use LNJ series jet mill classifier to jet mill for 60 minutes to obtain nanometer ultrafine surface hydrophobic modification with an average particle size of 70nm mineral...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com