Flexible-arm robot for single-pore laparoscopic minimally-invasive operation

A minimally invasive surgery, flexible arm technology, applied in surgical robots, surgery, applications, etc., can solve the problems of large size of surgical robots and many skin incisions, to enhance operability and precision, reduce pain, and reduce structure size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

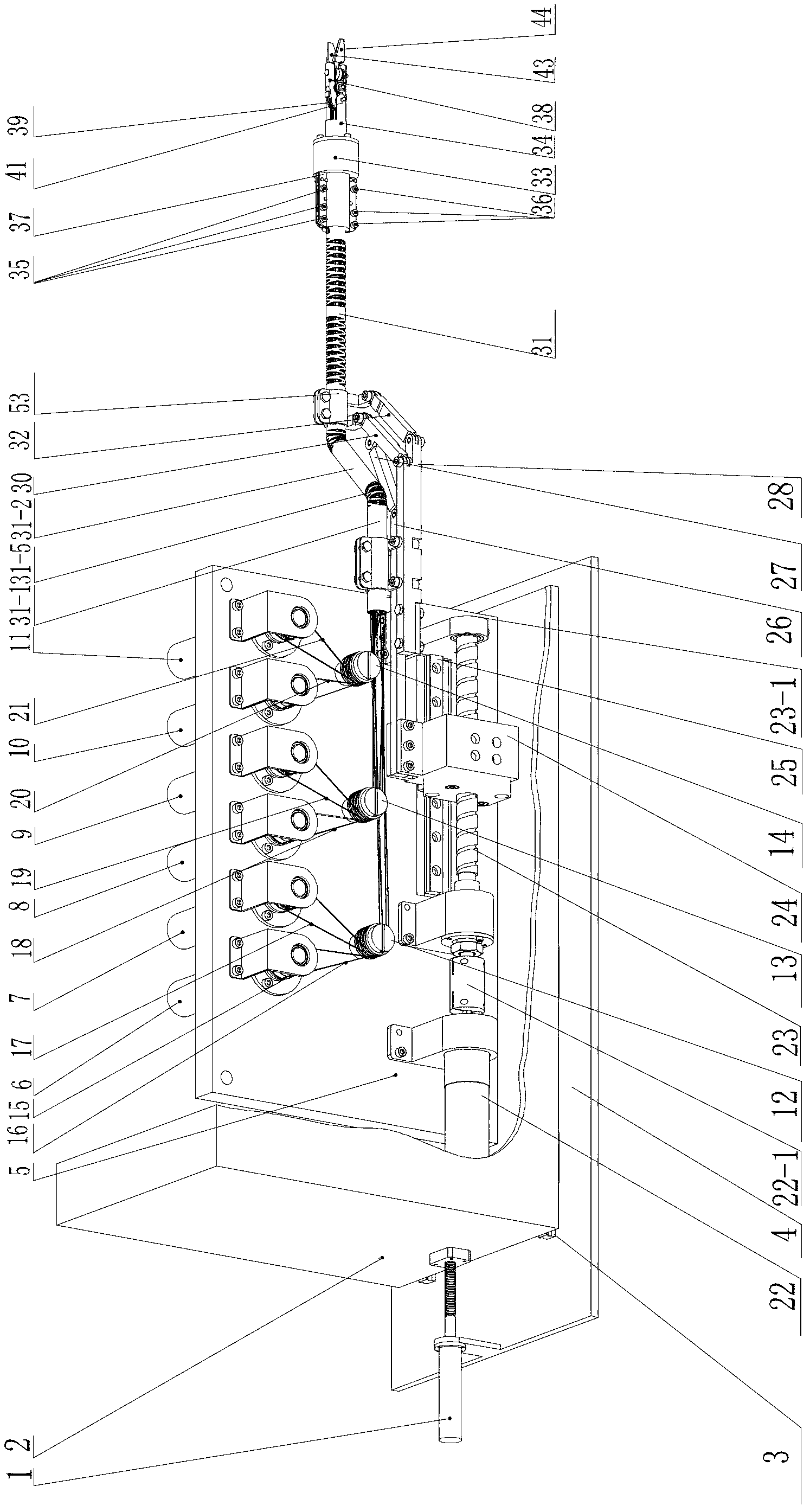

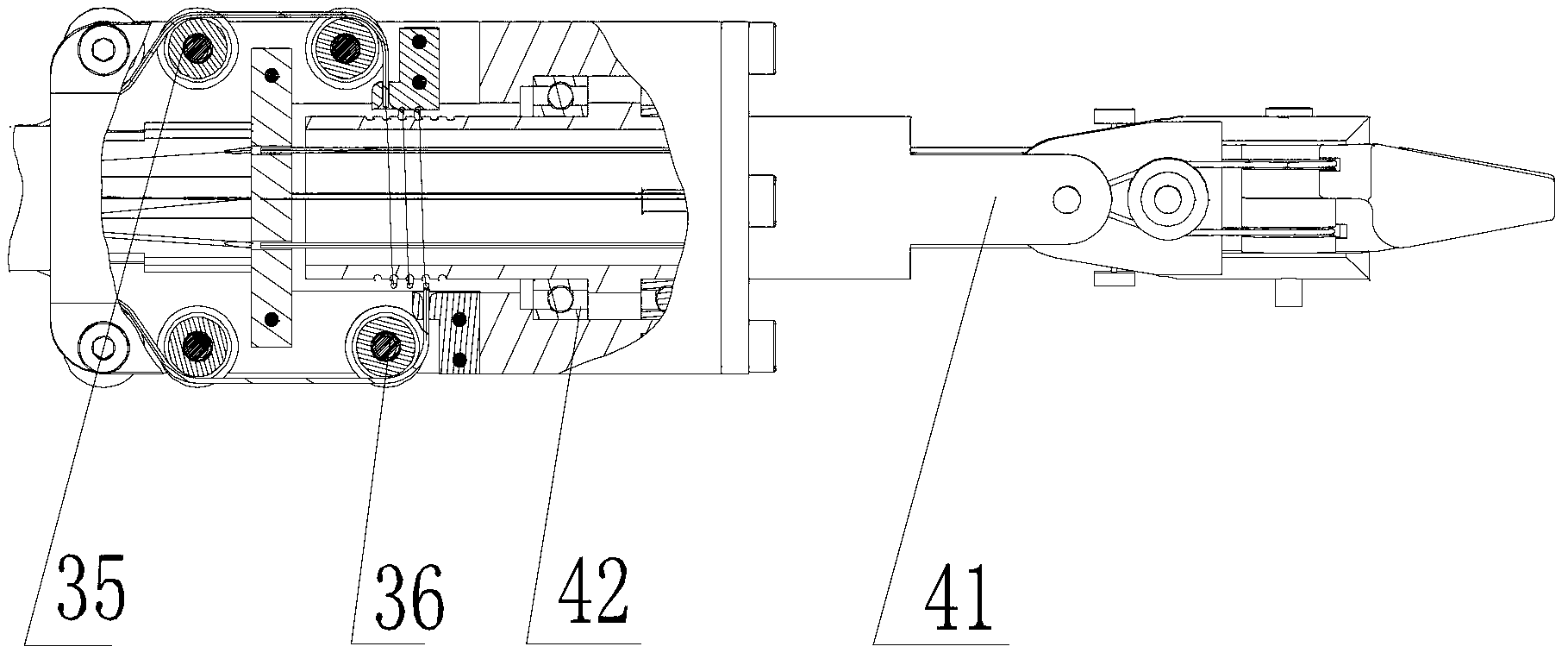

[0017] Specific implementation mode one: combine Figure 1-Figure 4 Describe this embodiment, the robot of this embodiment comprises a first motor 1, a drive box 2, a first guide rail 3, a base 4, a support plate 5, a second motor 6, a third motor 7, a fourth motor 8, and a fifth motor 9. The sixth motor 10, the seventh motor 11, the first guide column 12, the second guide column 13, the third guide column 14, the first driving wire 16, the second driving wire 17, the third driving wire 18, the fourth Driving wire 19, fifth driving wire 20, sixth driving wire 21, first flexible arm support 30, flexible arm 31, second flexible arm support 32, pivot joint 33, wrist connecting rod 34, first set of guide wheels 35. The second set of guide wheels 36, wrist joint 38, clamping clamp guide wheel 39, clamping clamp 40, first finger 43, second finger 44, guide roller 45, first shaft 46, second shaft 47, fixed Clip 53, two sets of fixed splints 37, two mounting ears 41, two deep groove ...

specific Embodiment approach 2

[0027] Specific implementation mode two: combination figure 1 and Figure 4 Describe this embodiment, the robot of this embodiment also includes fixed shaft 48, the connection mode of clamping pliers 40 and first finger 43 and second finger 44 is that fixed shaft 48 passes through clamping pliers 40 and connects with clamping pliers guide wheel The radial direction of 39 is on the same straight line, the end of the first finger 43 is provided with the first connecting ring 49, the end of the second finger 44 is provided with the second connecting ring 50, the first connecting ring 49 and the second connecting ring 50 Set on the fixed shaft, the advantage of this structure is that the second motor and the third motor can flexibly drive the first finger and the second finger through the first driving wire and the second driving wire, so as to realize the flexibility of the first finger and the second finger sports. Other implementation manners are the same as the specific impl...

specific Embodiment approach 3

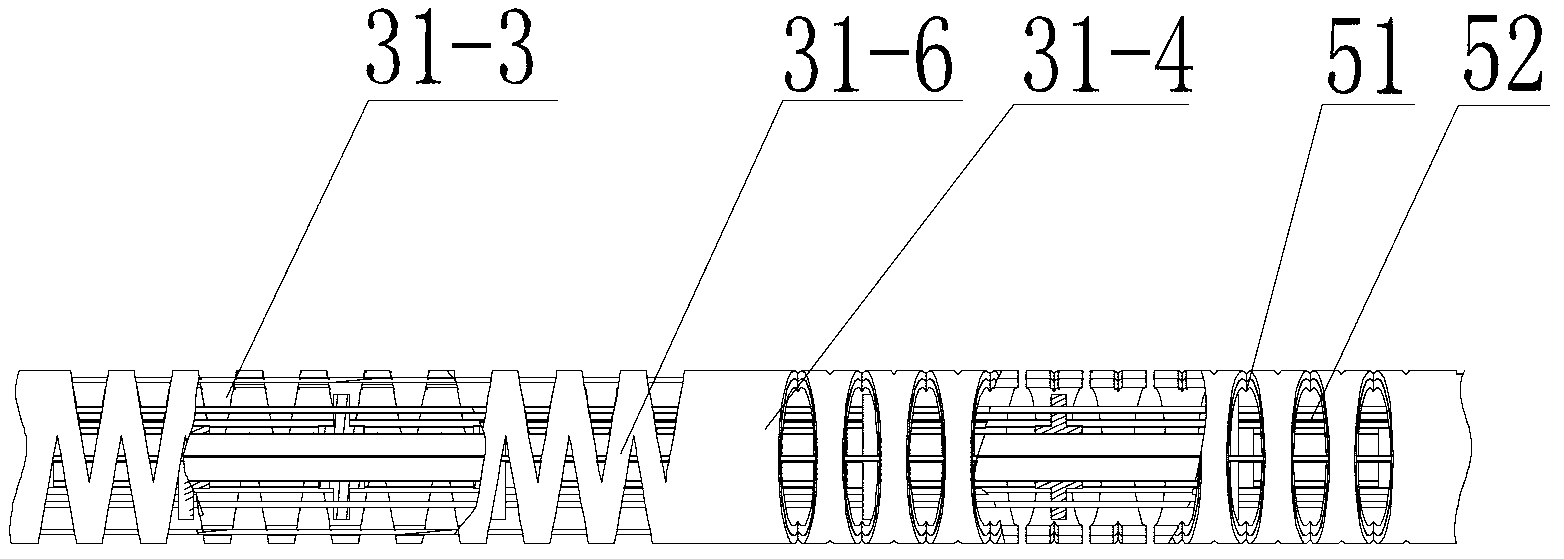

[0028] Embodiment 3: The flexible arm 31 of this embodiment is a flexible arm made of Nitinol material. The advantage of this material is that it has a large elastic deformation under the premise of ensuring a certain rigidity. Other implementation manners are the same as the specific implementation manner 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com