Permanent magnet pulley of grinding wheel ash magnetic separator

A technology of permanent magnet drum and magnetic separator, applied in the field of permanent magnet drum and magnetic separator, can solve the problems of complex structure, low recovery rate of high-tech steel, inconvenient installation and use, etc., so as to improve the quality of concentrate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

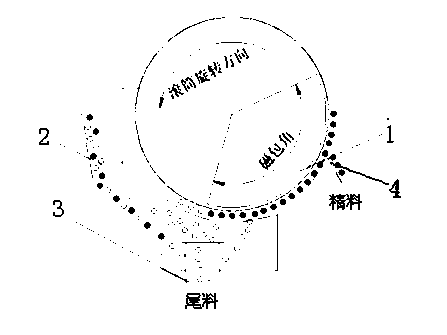

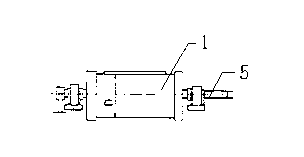

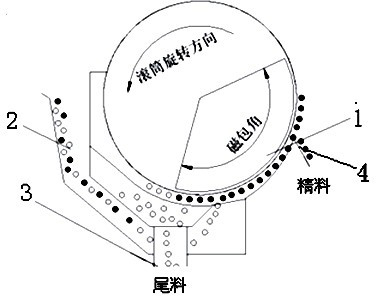

[0020] figure 1 It is a front view of an embodiment of the present invention; figure 2 It is a front view of an embodiment of the present invention.

[0021] like figure 1 and figure 2 Shown: a permanent magnet drum of a grinding wheel gray magnetic separator, including a drum shell 1, a main shaft 5 passing through the center of the drum shell 1, and a magnetic system (not shown) arranged in the drum shell 1 and connected to the main shaft 5, The magnetic system includes main magnetic poles, auxiliary magnetic poles and yokes, wherein the main magnetic poles and auxiliary magnetic poles are alternately arranged in the drum shell with the same poles, and the N levels and S poles are arranged alternately to form an open magnetic system, which can Reach the effect of magnetism gathering, wherein, the magnetic field intensity of the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com