Production process method of small-caliber cold-drawing seamless steel tube used for boiler

A technology of seamless steel pipe and production process, which is applied in the direction of metal rolling, etc., can solve the problem that the small tube billet cannot meet the unit weight of the product, and achieve the effects of increasing the heating length, reducing production energy consumption, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with specific embodiments.

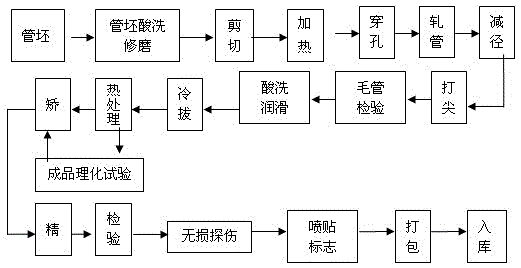

[0029] A production process for small-diameter cold-drawn seamless steel pipes for boilers, the specific steps are:

[0030] After pickling, the tube billet is ground with a grinding wheel to remove surface defects, and the ground tube billet is hoisted by a crane to the bar shearing machine to cut it to the required length, and the tube billet is transported to the feeding manipulator of the annular heating furnace by the conveying roller table , the manipulator clamps the tube blank and sends it into the furnace, rotates to form an angle of 35° with the radial line, places the tube blank, and increases the heating length. After the tube blank is heated to 1180-1220°C, it is rotated by the discharge manipulator to form an angle of 35° with the radial line. After the tube blank is clamped, it is reversely rotated by 35° and returned to place the tube blank on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com