Automatic stone side line grinding and polishing machine with quick head switching device

A technology for grinding and polishing machines and stone materials, which is applied to the parts of grinding machine tools, grinding/polishing equipment, grinding/polishing safety devices, etc., and can solve problems such as lines being easily broken by grinding wheels, poor product quality, and high investment costs , to achieve the effect of simple and reliable positioning structure, good force, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

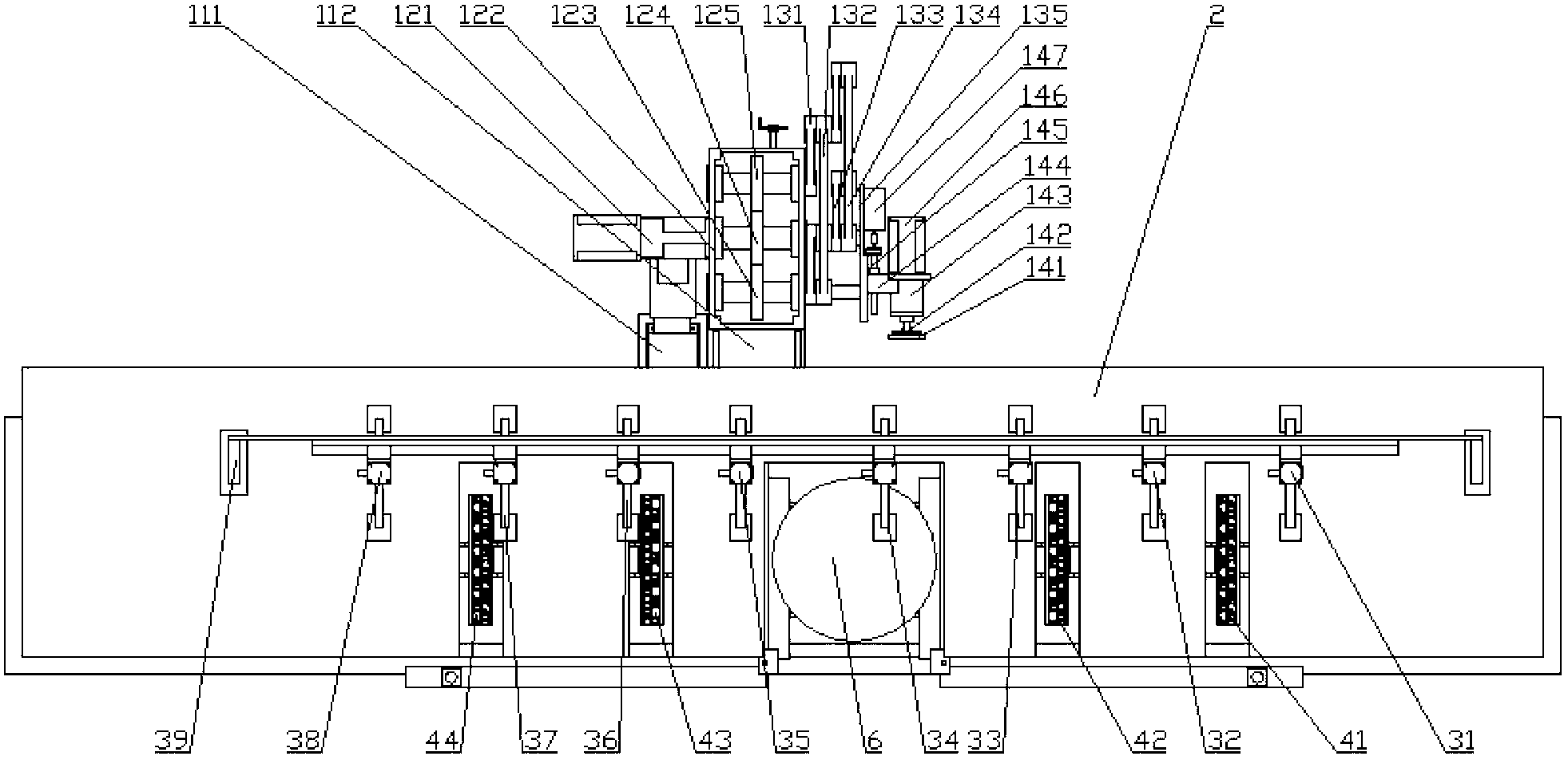

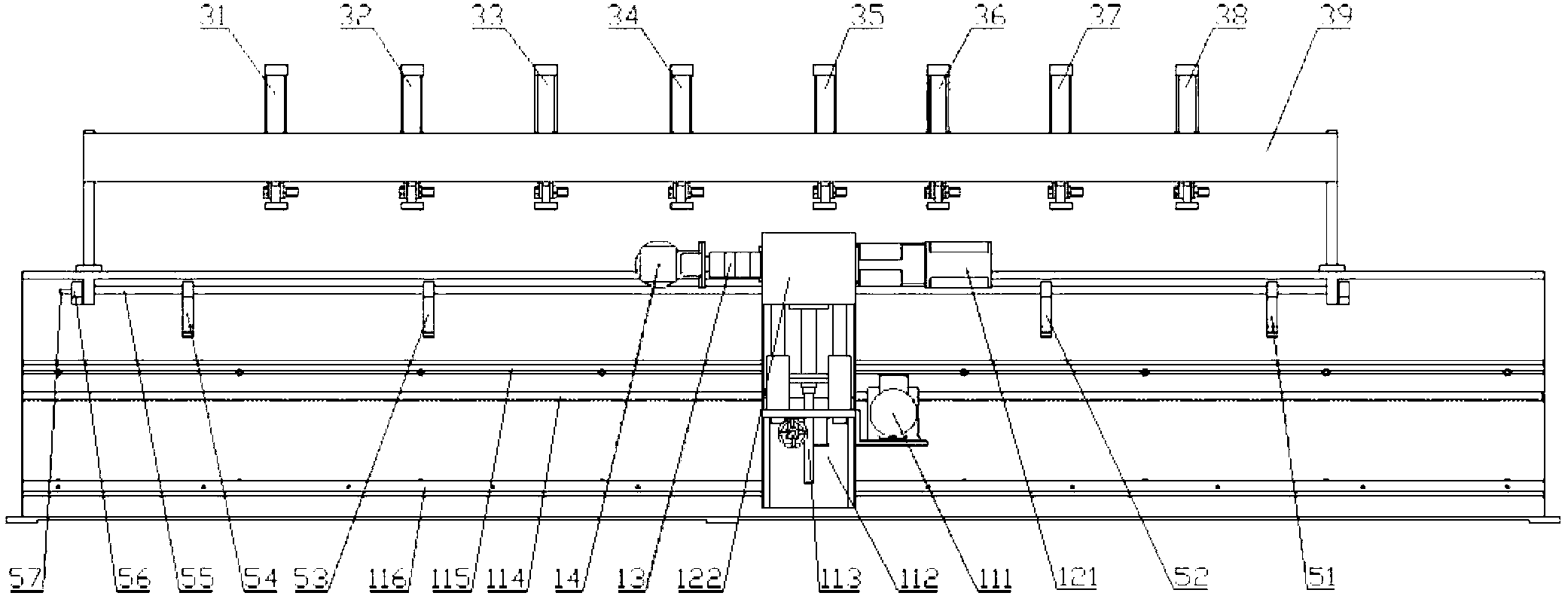

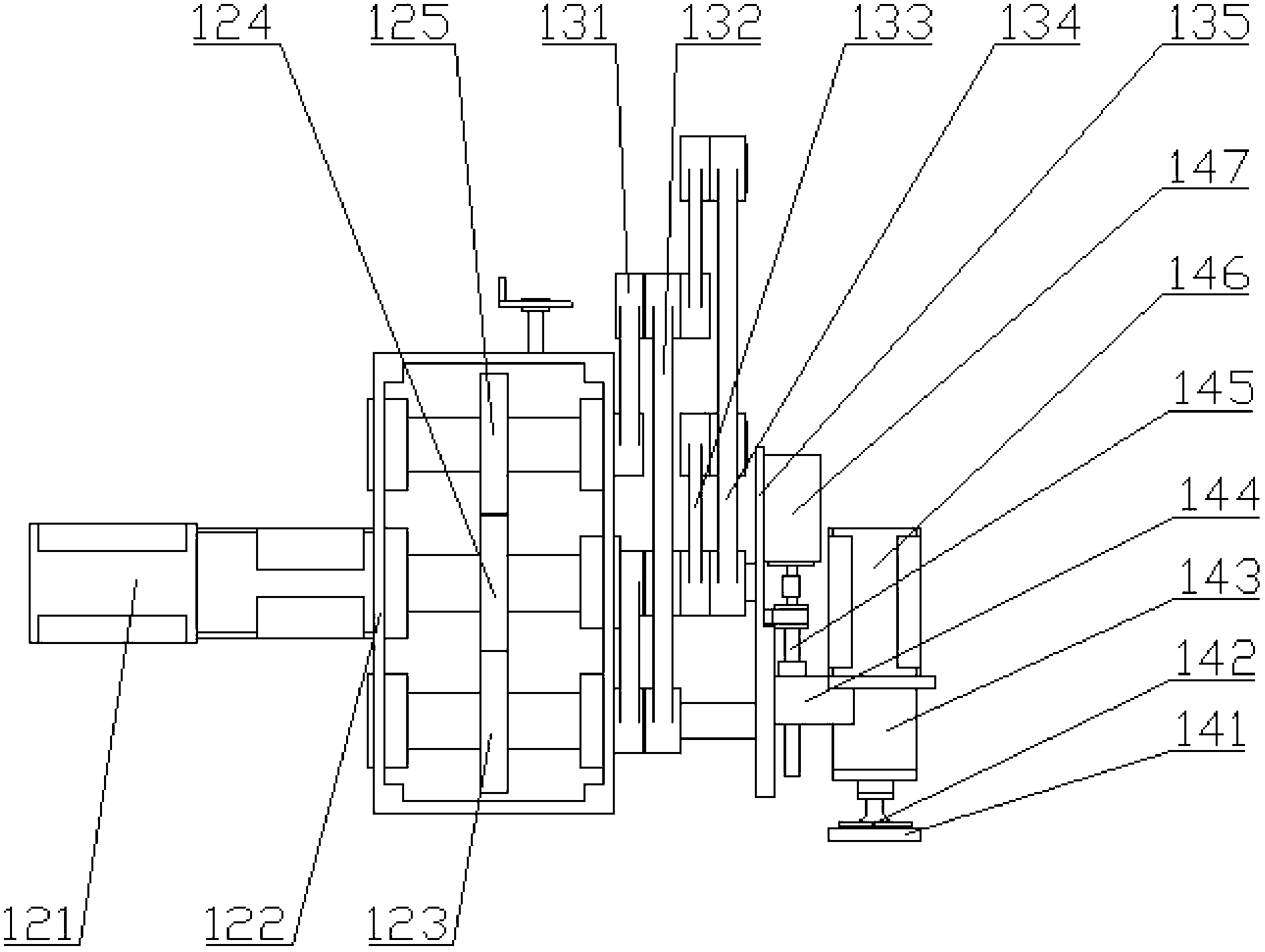

[0031] see figure 1 and Figure 6As shown, a quick head-changing stone edge automatic grinding and polishing machine includes a gear box 122 and a swing mechanism connected to each other. A spindle head part 14 is installed on the other side of the swing mechanism. Carry out the grinding and polishing of stone material, main shaft head part 14 comprises main shaft head support 135, servomotor 147 and bearing 144 respectively fixed on the main shaft head support 135, the output end of servomotor 147 is connected with lead screw nut mechanism 145, servo Motor 147 drives lead screw nut mechanism 145, also is fixed with main shaft motor 146 on support 144, is connected with main shaft 143 with main shaft motor 146, drives the rotation of main shaft, thereby realizes the rotation of cutter, is connected with quick changer on the other end of main shaft 143. The head device 142 is fitted with a tool 141 on the quick head changing device 142 ; the support 144 moves back and forth al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com