Cleaning preparation method of laminated composite metal hydroxide

A technology of hydroxide and layered compounding, which is applied in the direction of chemical instruments and methods, cobalt compounds, aluminum compounds, etc., can solve the problems of unavoidable by-product formation and washing process, and achieve low cost and energy consumption, simple process flow, The effect of saving water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

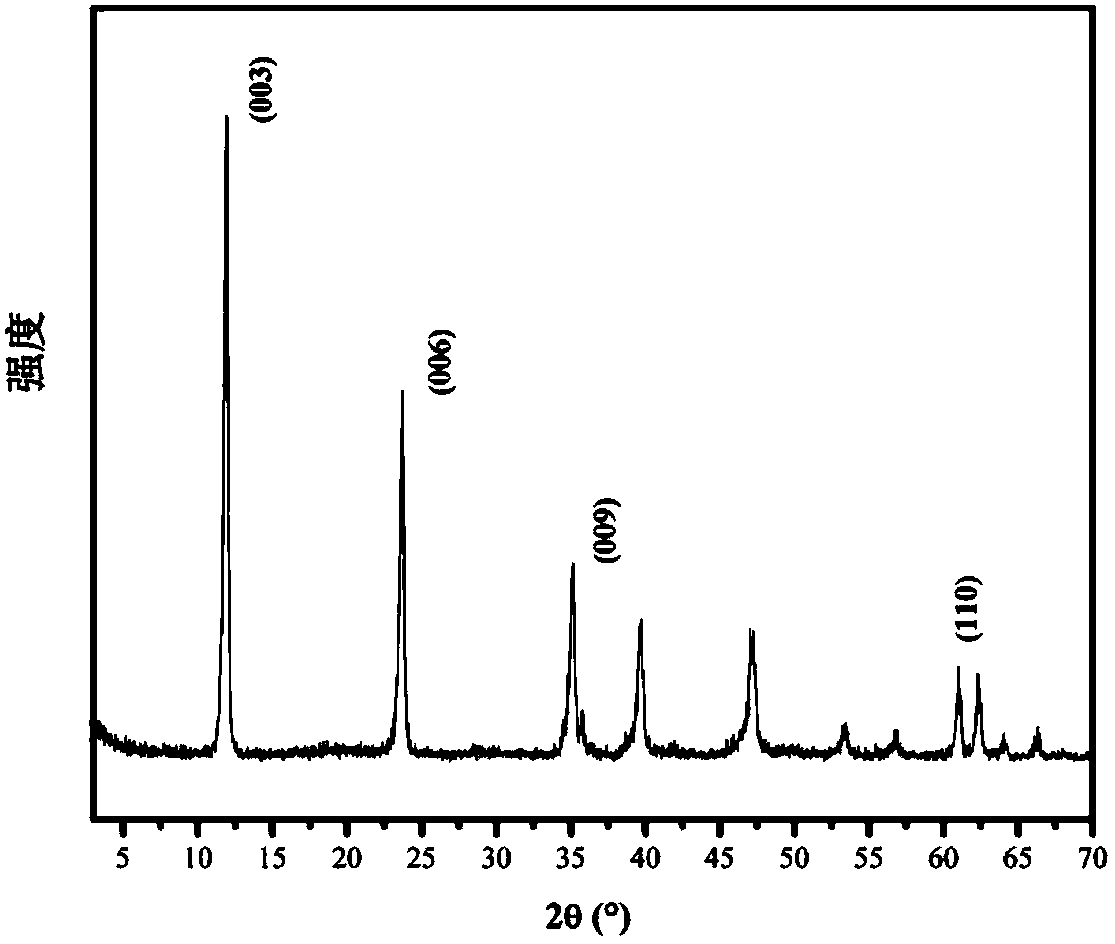

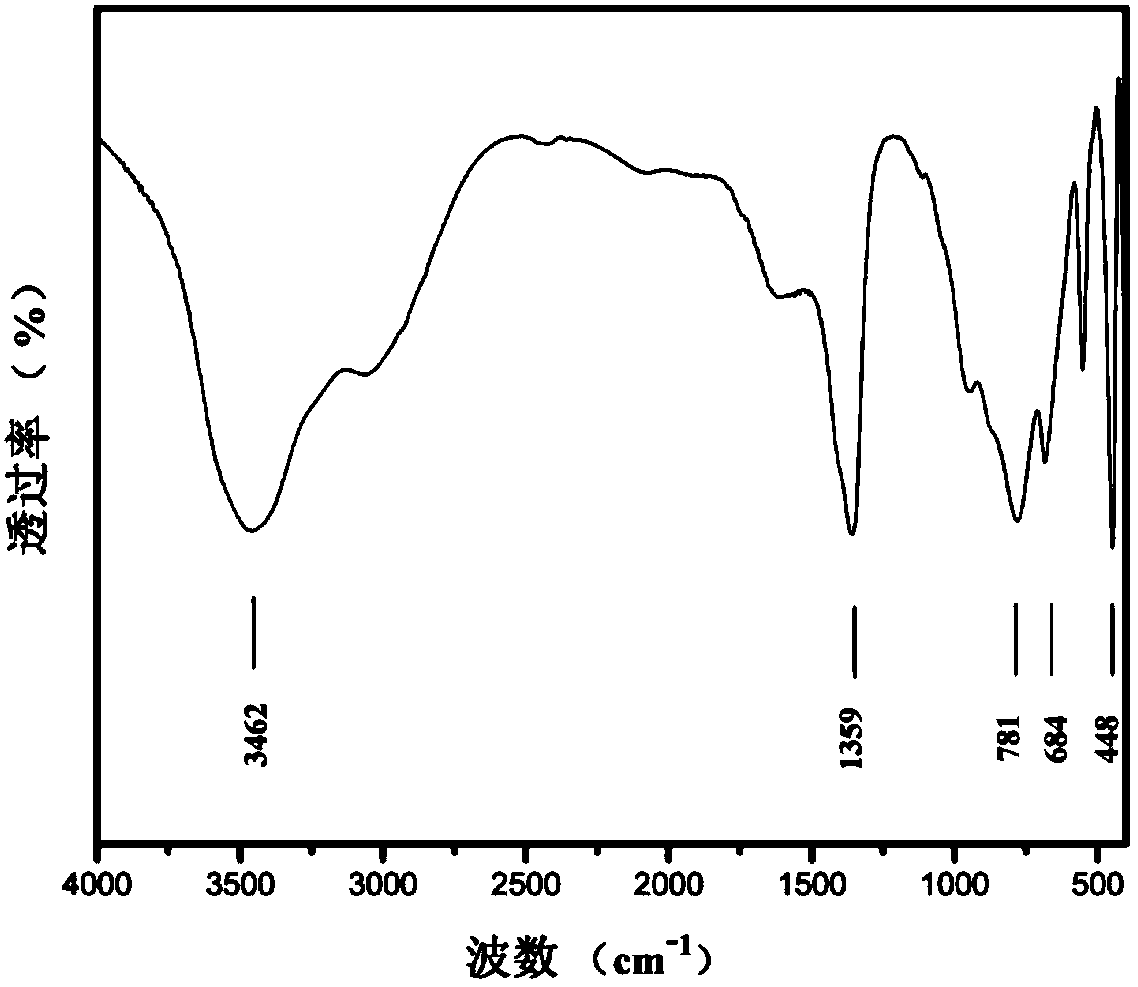

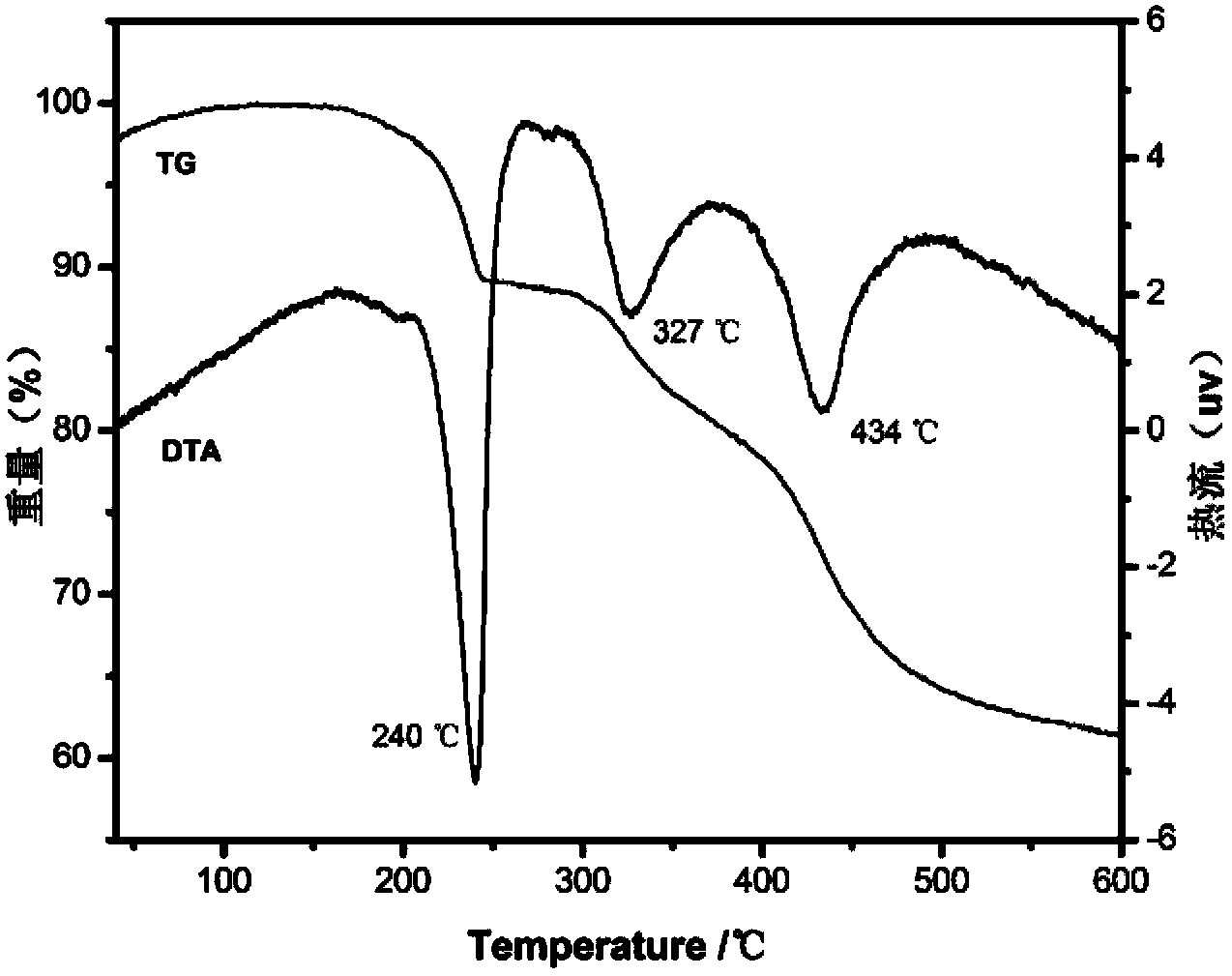

[0029] 4MgCO 3 ·Mg(OH) 2 ·5H 2 O, Mg(OH) 2 , Al(OH) 3 Mix according to the molar ratio of 1:11:8; take 87.6 g of the above mixture and place it in 800 g deionized water, add it to the rotary liquid film reactor, disperse it for 5 minutes at a speed of 5000 rpm, and transfer it to a closed reaction In the container, the temperature was raised to 180 °C under stirring conditions, the pressure was 1 Mpa, the stirring speed was 300 rpm, and the reaction was carried out for 6 hours. After centrifugation, the product was directly placed at 80 °C and dried for 8 hours, and the molecular formula was Mg 4 Al 2 (OH) 12 CO 3 4H 2 O's LDHs products.

[0030] The results of elemental analysis using the Japan Shimadzu ICPS-7500 elemental analyzer show that the product contains Mg:Al=2:1, and the product does not contain Na + and other hetero ions.

Embodiment 2

[0032] 2ZnCO 3 ·3Zn(OH) 2 , Zn(OH) 2 , Al(OH) 3 Mix according to the molar ratio of 1:3:4 respectively, take 23.2 g of the above mixture and place it in 200 g deionized water, add it to the rotary liquid film reactor, disperse it for 5 minutes at a speed of 5000 rpm, and transfer it to the belt reflux device In the reactor, under the condition of stirring, heating under normal pressure and reflux reaction for 48 hours, the obtained product was centrifuged and directly placed in 80 ℃ and dried for 8 hours, and the molecular formula was Zn 4 Al 2 (OH) 12 CO 3 4H 2 O's LDHs products.

Embodiment 3

[0034] NiCO 3 2Ni(OH) 2 4H 2 O, Ni(OH) 2 , Al(OH) 3 Mix according to the molar ratio of 1:1:2 respectively, take 46.9 g of the above mixture, place it in 800 g deionized water, add it to the rotary liquid film reactor, disperse it for 5 minutes at a speed of 5000 rpm, and transfer it to the closed reaction In the container, the temperature was raised to 180°C under stirring conditions, the pressure was 1Mpa, the stirring speed was 300 rpm, and the reaction was carried out for 12 hours. After centrifugation, the product was directly placed at 80°C and dried for 8 hours, and the molecular formula was Ni 4 Al 2 (OH) 12 CO 3 4H 2 O's LDHs products.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com