Treatment method of anaerobic fermentation biogas slurry from livestock and poultry raising

A technology of anaerobic fermentation and biogas slurry treatment, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc. Unbalance and other problems, to achieve the effect of improving water quality, simple and easy process, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

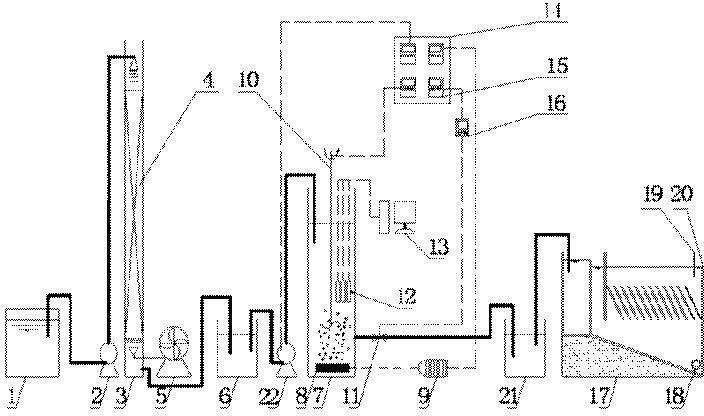

[0015] Example 1: Take the pilot test of anaerobic fermentation biogas slurry treatment in a chicken farm in Shanghai as an example.

[0016] Fresh chicken manure is diluted with water and passed through a vibrating screen to remove impurities such as chicken feathers, and then enters a fully mixed fermentation tank for fermentation to produce biogas. The water quality conditions of the effluent anaerobic fermentation biogas slurry are measured as follows: the average COD is 9200mg / L, the average ammonia nitrogen is 2700mg / L, The average total phosphorus is 100mg / L, and the average SS is 7000mg / L. It is high-concentration wastewater with high organic load, high ammonia nitrogen and high phosphorus load, and the carbon and nitrogen ratio is low.

[0017] After the biogas slurry enters the storage tank 1, lime is added to adjust the pH to 12, and the water is fed from the top of the ammonia stripping column 3 through the water pump 2. The column is filled with hollow ball packin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com