Method for improving treatment efficiency of sewage plant by utilizing bypass sludge activity enhancing technology

A technology for sewage plants and sludge, which is applied in the field of improving the treatment efficiency of sewage plants by using bypass sludge activation technology, which can solve the problems of inability to perform anoxic or anaerobic hydrolysis, inability to release SCOD, and ineffective utilization, etc., to achieve The effect of reducing output, improving removal capacity, and improving sludge stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

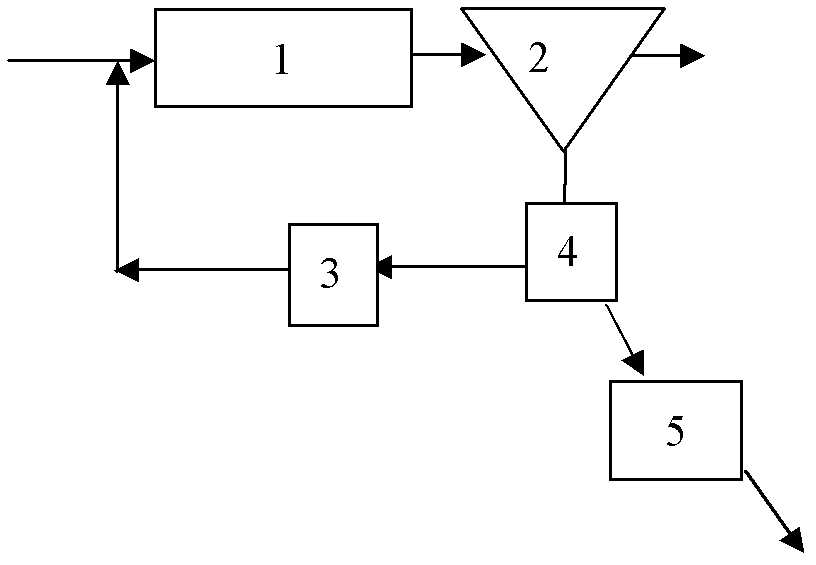

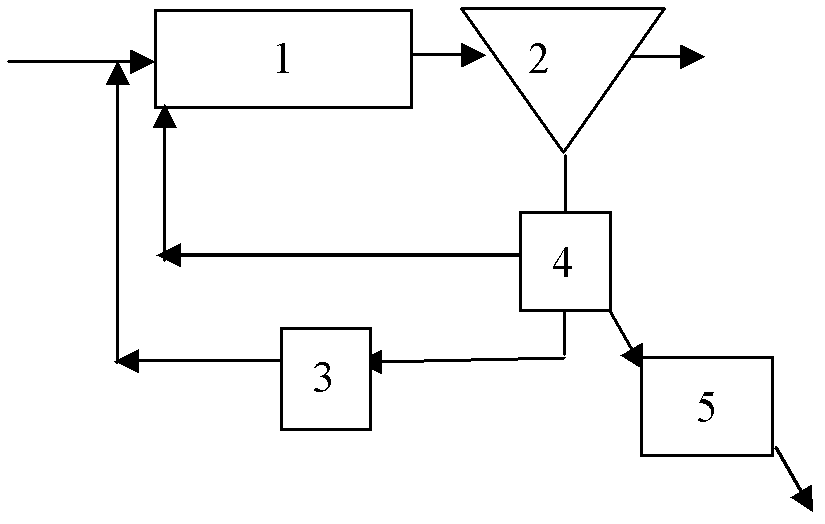

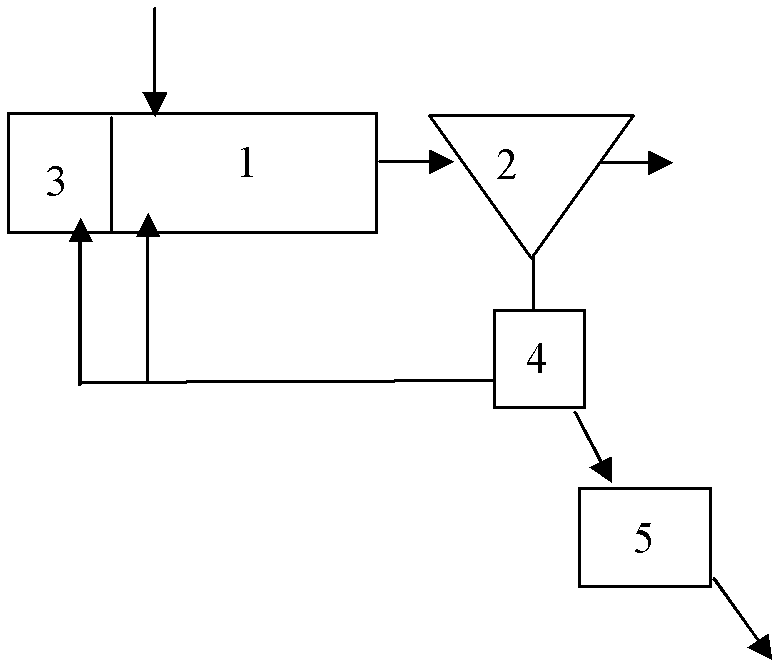

[0033] Such as figure 1 As shown, a method for improving the treatment efficiency of a sewage plant by using the bypass sludge activation enhancement technology includes the following steps: after the primary pretreated sewage passes through the main biological pool 1 for secondary treatment (the sewage is in the main biological pool, passed through Aerobic, anoxic or anaerobic process, to achieve the removal of pollutants and the reduction of concentration) into the secondary settling tank 2, in which the mud and water are separated, the supernatant of the secondary settling tank is discharged, and the active sewage concentrated in the secondary settling tank The mud is transported to the bypass biological pool (hereinafter referred to as the SART pool) 3 through the sludge return pump 4 and the pipeline, and returns to the water inlet of the main biological pool after being treated in the SART pool through aerobic, anoxic, and anaerobic biochemical processes, resulting in Th...

Embodiment 2

[0041] Such as figure 1 As shown, a method for improving the treatment efficiency of a sewage plant by using the bypass sludge activation enhancement technology includes the following steps and processes: the sewage that has undergone primary pretreatment flows into the secondary sedimentation tank after secondary treatment in the main biological tank, and then flows into the secondary sedimentation tank in the secondary sedimentation tank. The sludge and water are separated in the tank, and the supernatant of the secondary sedimentation tank enters the subsequent advanced treatment. The concentrated activated sludge in the secondary sedimentation tank is transported to the SART tank through the sludge return pump and pipeline, and undergoes aerobic, anoxic and anaerobic biochemical processes in the SART tank. After the process is treated, it is returned to the water inlet of the main biological pool, and the excess sludge generated is processed through the sludge treatment pro...

Embodiment 3

[0048] Such as figure 1 As shown, a method for improving the treatment efficiency of a sewage plant using the bypass sludge activation enhancement technology includes the following steps: the sewage that has undergone primary pretreatment flows into the secondary sedimentation tank after secondary treatment in the main biological tank, and in the secondary sedimentation tank Separation of mud and water, discharge of the supernatant from the secondary settling tank, and the concentrated activated sludge from the secondary settling tank is transported to the SART tank through the sludge return pump and pipeline, and then returned to the SART tank after being treated by aerobic, anoxic and anaerobic biochemical processes. At the water inlet of the main biological pool, the excess sludge generated is processed through the sludge treatment process unit. The main design parameters of each treatment unit or structure are as follows:

[0049] The proportion of SART pool volume to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com