Teflon-polybenzoate compounded product and preparation method thereof

A technology of polytetrafluoroethylene and composite products, applied in the field of polytetrafluoroethylene-polyphenylester composite products and their preparation, can solve the problems of low limit PV value, non-abrasion resistance and easy creep of polytetrafluoroethylene products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

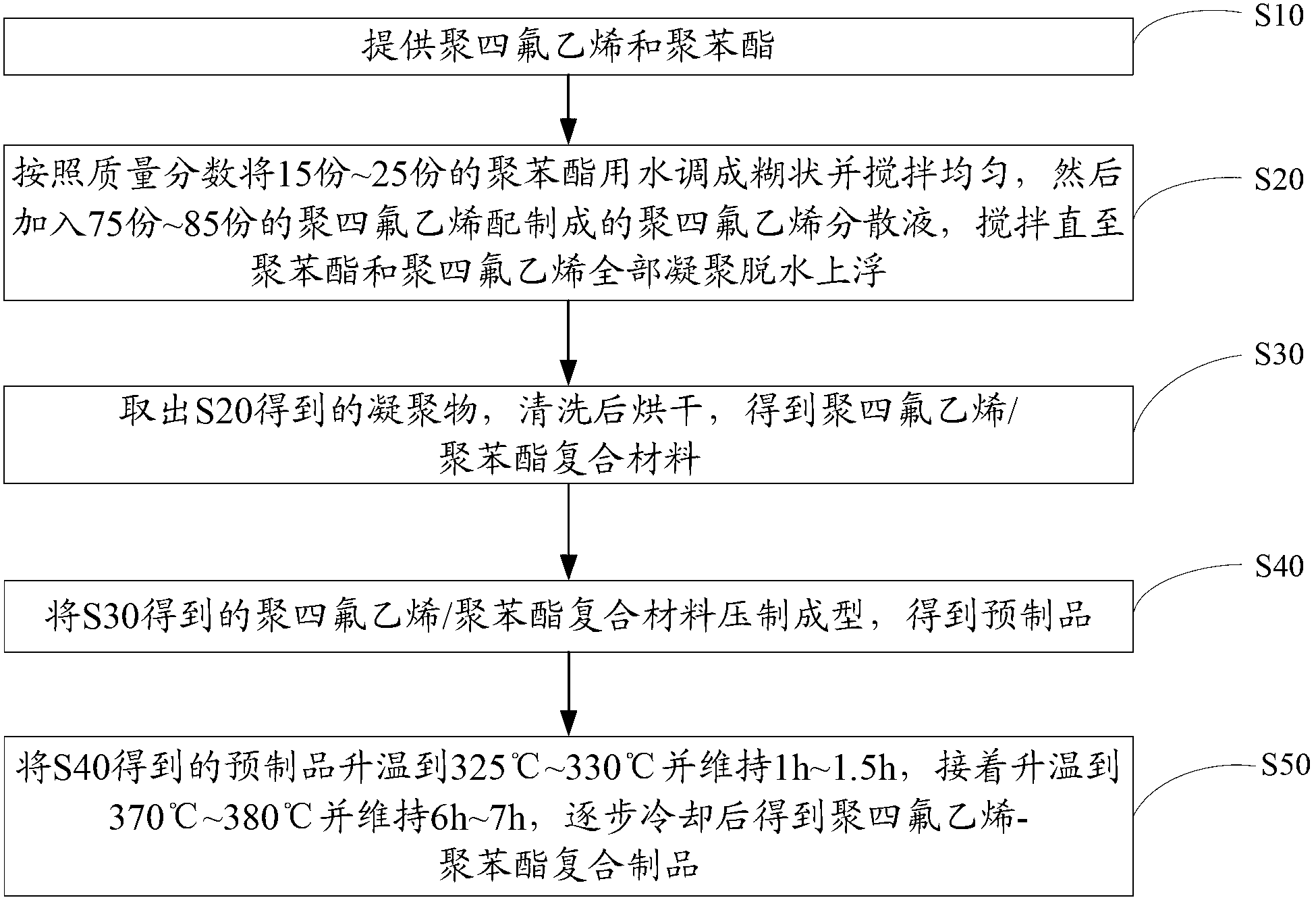

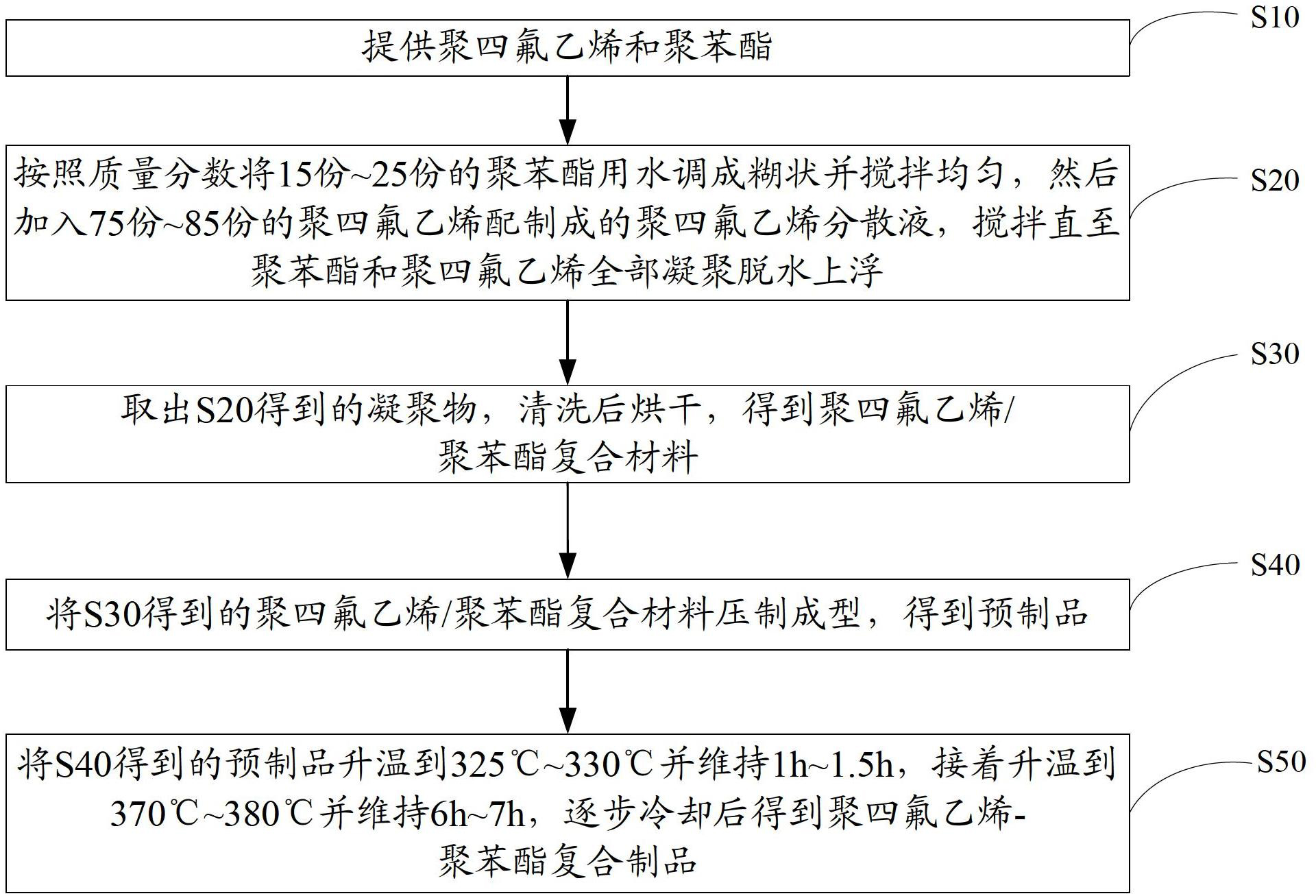

[0030] Such as figure 1 The preparation method of above-mentioned polytetrafluoroethylene-polyphenyl ester composite product shown, comprises the steps:

[0031] S10. Provide polytetrafluoroethylene and polyphenylene.

[0032] Among them, the number average molecular weight of polytetrafluoroethylene is greater than 10 million, and the thermal weight loss of polyphenylene is less than 0.5%.

[0033] The provided polytetrafluoroethylene and polyphenylene need to be pretreated, and the pretreatment is generally selected to be placed at 21°C~25°C for 36h~50h. Special attention is not to store at room temperature below 19°C, because 19°C is the crystal transition temperature of polytetrafluoroethylene.

[0034] S20. According to the mass fraction, make 15-25 parts of polyphenylene into a paste with water and stir evenly, then add 75-85 parts of polytetrafluoroethylene dispersion prepared by polytetrafluoroethylene, and stir until the polyphenylene The ester and polytetrafluoroe...

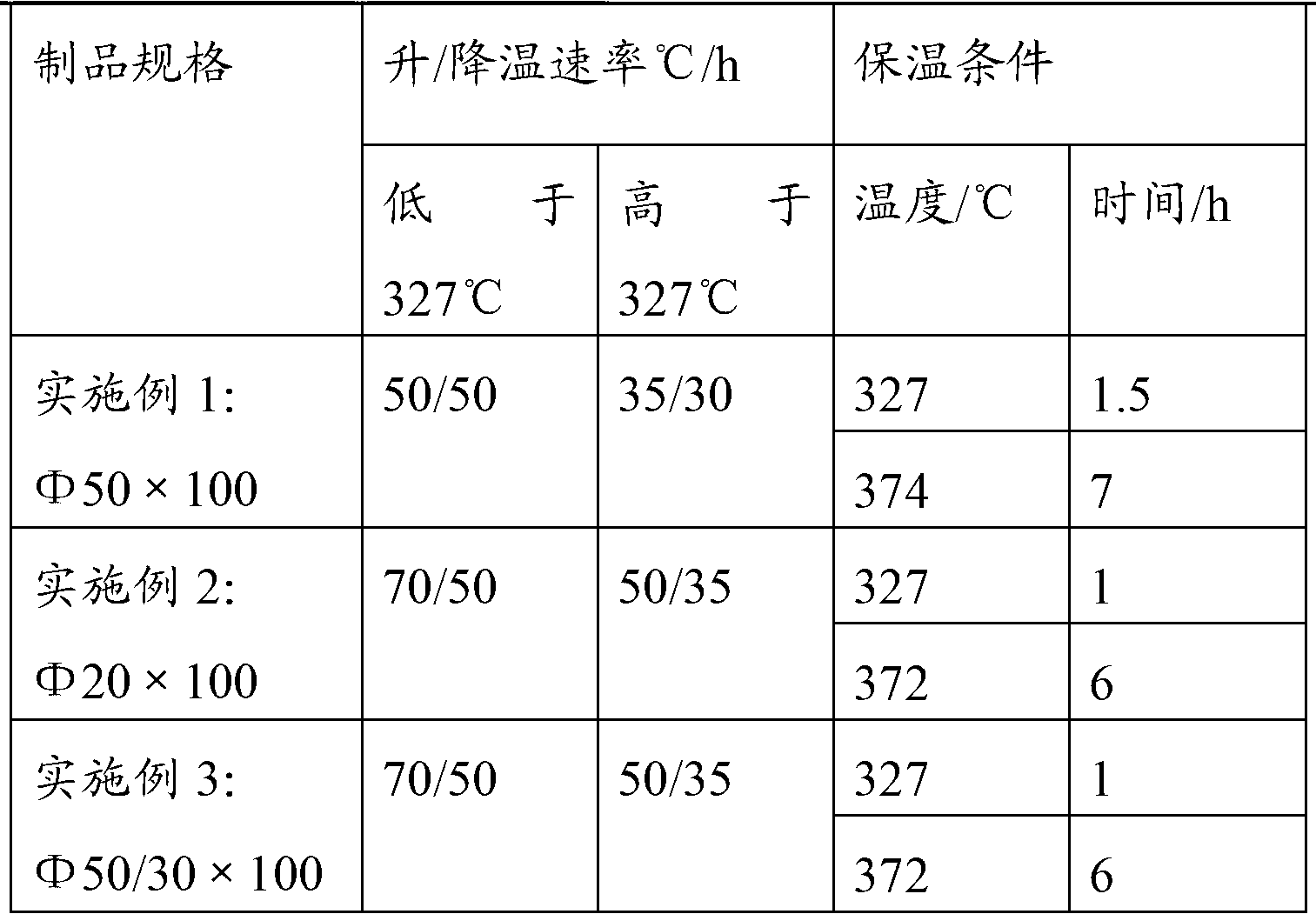

Embodiment 1

[0078] Dimensions and appearance: outer diameter: 50.1mm; height: 102mm; the appearance is uniform in color, free of impurities, cracks and any mechanical damage.

[0079] Physical and mechanical properties: tensile strength: 13.8Mpa; elongation at break 272%; compressive strength 36Mpa; compressive elastic modulus 821Mpa; hardness (Shore D) 63, friction coefficient 0.22; average wear coefficient 2.4g / h (×10 -5 ); Density 1.96g / cm 3 .

Embodiment 2

[0081] Dimensions and appearance: outer diameter: 20.05mm; height: 102mm; the appearance is uniform in color, free of impurities, cracks and any mechanical damage.

[0082] Physical and mechanical properties: tensile strength: 14.7Mpa; elongation at break 285%; compressive strength 35Mpa; compressive elastic modulus 850Mpa; hardness (Shore D) 64, friction coefficient 0.23; average wear coefficient 2.2g / h (×10 -5 ); Density 1.97g / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive modulus of elasticity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap