Multiphase composite decoupling material and preparation method thereof

A technology of decoupling materials and flexible materials, applied in the field of composite materials, can solve problems such as unsatisfactory requirements and lower resonance frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

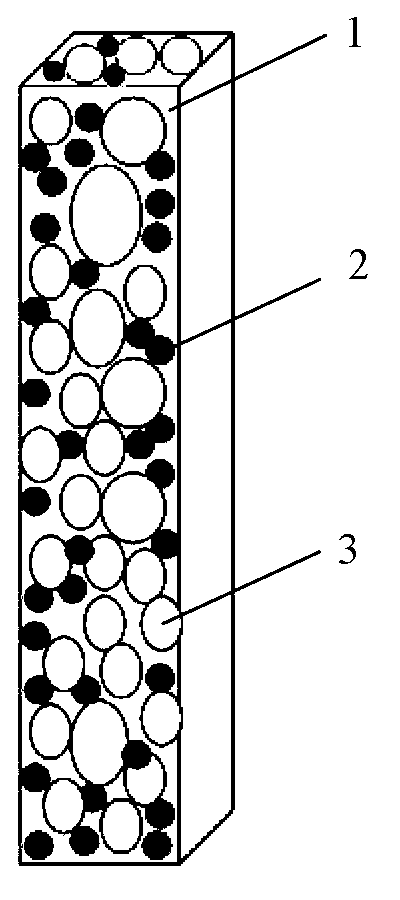

[0022] The structure of the multiphase composite decoupling material in this embodiment is as follows figure 1 As shown, it consists of flexible materials 1 (such as polyurethane, rubber, epoxy resin, etc.), heavy particles (tungsten powder, titanium powder, barium sulfate particles, etc.) and light particles (alumina, nickel powder, etc.) 2, hollow glass Microbeads 3 constitute. The multiphase composite decoupling material is completed by infusion process. First of all, according to the properties of the composite material required by the actual application, design the mass percentage of each phase material in the composite material, accurately weigh each component according to this percentage, mix all the added materials except the flexible material, and stir evenly in the same direction with a stirring rod 3 minutes to mix well. Prepare a flexible material (such as polyurethane), add an appropriate amount of flexible material to a three-necked bottle in a constant tempera...

Embodiment 2

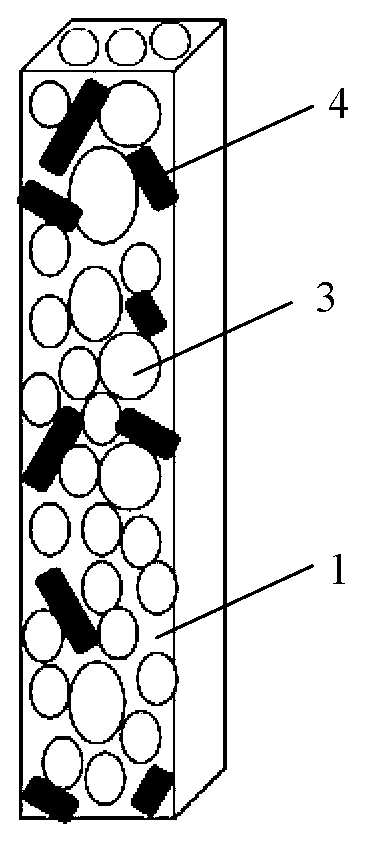

[0024] The structure of the multiphase composite decoupling material in this embodiment is as follows figure 2 As shown, it includes flexible material 1 (such as polyurethane, rubber, epoxy resin, etc.), thin sheet 4 made of heavy particles (tungsten powder, titanium powder, barium sulfate particles, etc.), and hollow glass microspheres 3. The preparation method of the multiphase composite decoupling material is the same as that in Example 1. The sheet 4 composed of heavy particles is composed of heavy particles (such as tungsten powder) with a mass percentage greater than 80% and flexible materials (such as epoxy resin), and its preparation process is similar to the preparation of multi-phase composite decoupling materials. , after curing, the whole composite material is cut into thin slices with a precision cutting machine, and these flakes are added to the flexible material as additives to form a multi-phase composite decoupling material, which is characterized by uneven d...

Embodiment 3

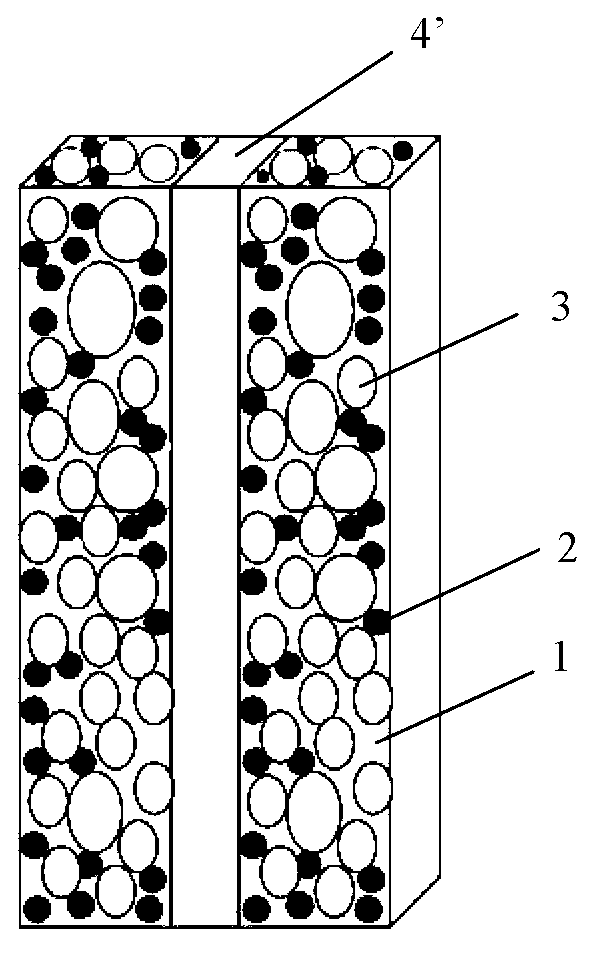

[0026] The structure of the multiphase composite decoupling material in this embodiment is as follows image 3 As shown, the thin sheet 4' composed of high-impedance heavy particles separates the decoupling material composed of flexible material 1, heavy and / or light particles 2 and hollow glass microspheres 3 into two parts. The composition and preparation of the sheet 4' composed of high-impedance heavy particles (tungsten powder, titanium powder, barium sulfate particles, etc.) are the same as in Example 2, and the decoupling material composed of low-impedance flexible materials and additives is the same as in Example 1. . In this case, when the sound wave is transmitted from a certain array element to an adjacent array element, it is firstly transmitted from the high impedance material of the element to the decoupling material, and attenuated by the scattering of hollow glass beads and particles in the low impedance flexible material. When the sound wave is transmitted fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com