Antistatic environment-friendly communication equipment electrified cleaning agent

An environment-friendly, communication equipment technology, applied in the direction of detergent composition, surface active detergent composition, organic detergent composition, etc., can solve the problems such as charged cleaning agents for electronic equipment that have not yet been found, and achieve enhanced anti-fouling ability, Strong compatibility and good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

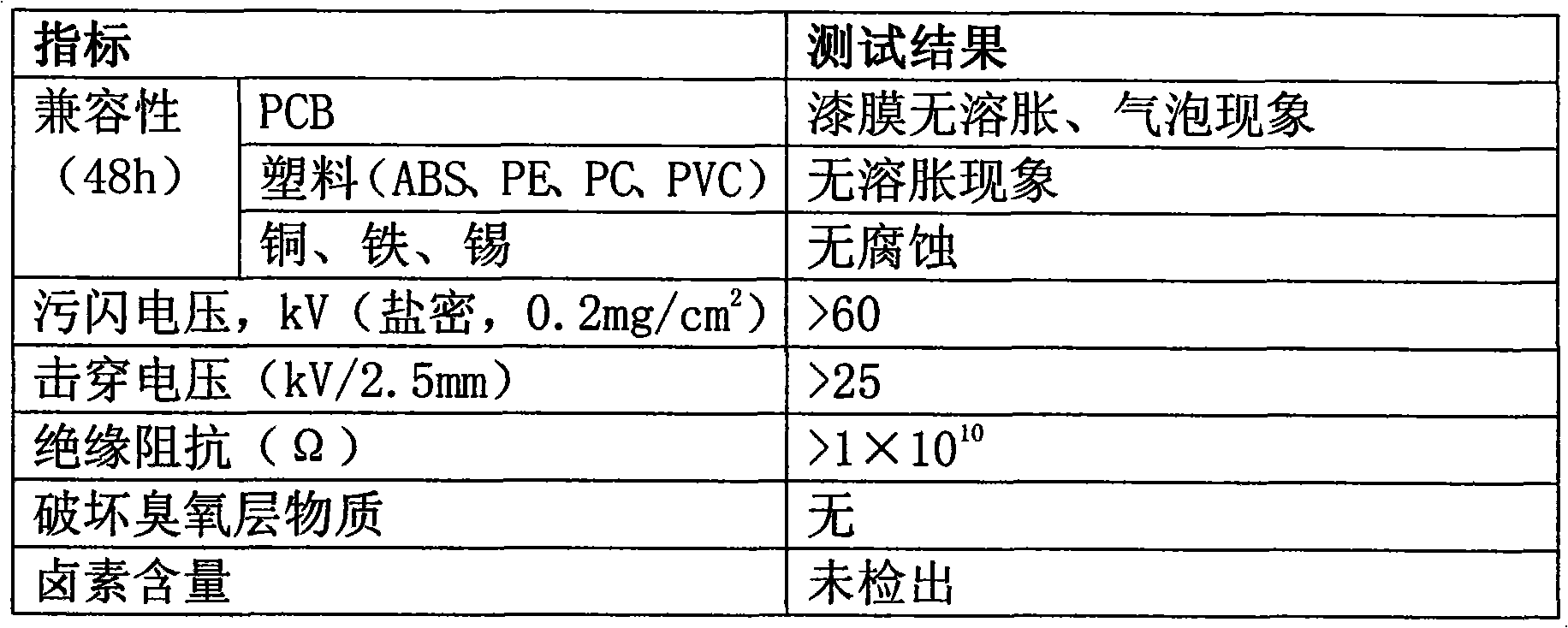

Examples

Embodiment 1

[0028] Get dipropylene glycol 60kg, octamethylsiloxane 15kg, methyl silicone oil 6.8kg, SMD-40 solvent oil 18kg, antistatic agent: isostearyl ethyl imidazolinium ethyl sulfate resin, (British Croda Company Incroquat ISIES) 0.2kg together into a stainless steel container, sealed, stirred at room temperature with a speed of 20-60 rpm for 5-10 minutes and mixed evenly to obtain the finished cleaning agent.

Embodiment 2

[0030] Get dipropylene glycol 60kg, octamethylsiloxane 15kg, methyl silicone oil 6.8kg, SMD-40 solvent oil 18kg, antistatic agent: the mixture of dicetyl dimethyl ammonium chloride and isopropanol composite resin, ( Incroquat DCMC) 0.2kg is put into stainless steel container together, seals, and shakes with the speed of 20-60 rev / min at room temperature and shakes for 5-10 minute and mixes evenly to obtain cleaning agent finished product.

Embodiment 3

[0032] Take 60kg of dipropylene glycol, 15kg of octamethylsiloxane, 6.8kg of methyl silicone oil, 18kg of SMD-40 solvent oil, and antistatic agent: sterazonium chloride (Incroquat S-85 of British Croda Company) 0.2kg Put it in a stainless steel container, seal it, and shake it at room temperature at a speed of 20-60 rpm for 5-10 minutes to mix evenly to obtain the finished cleaning agent.

[0033] The properties of the components used in the examples of the present invention are further described.

[0034] In the embodiment, different antistatic agents are added. The antistatic agent is a composite resin containing special cations. After cleaning, a thin film is formed on the surface of the communication equipment, which can enhance the anti-fouling ability of the equipment and has a relatively high High insulation.

[0035] The English name of antistatic agent is Antistatic agent, referred to as ASA. Since the volume resistivity of polymers is generally as high as 1010-1020...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com