Modified phenolic aldehyde composite insulation board and preparation method thereof

A technology of phenolic insulation board and composite insulation, applied in the direction of insulation, chemical instruments and methods, building components, etc., can solve the problems of slow drying speed, easy to fall off, long construction period, etc., and achieve increased bonding strength and pulling strength , Guarantee safety and economy, and the effect of short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

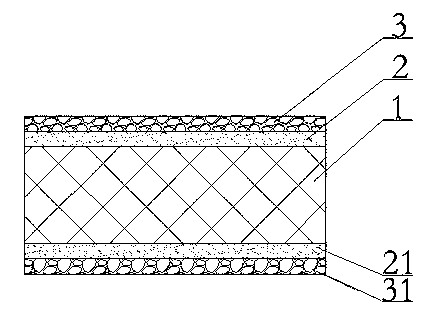

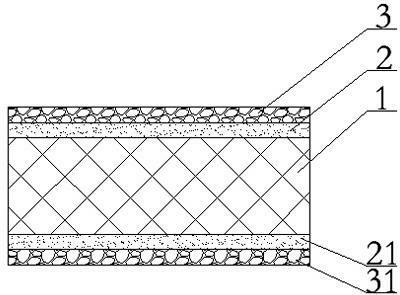

[0017] The present invention will be further described below in conjunction with accompanying drawing.

[0018] figure 1 As shown, a modified phenolic composite insulation board includes a modified phenolic insulation board 1, interface agent layers 2, 21 and quartz sand layers 3, 31, the upper and lower sides of the modified phenolic insulation board 1 are respectively provided with interface agent layers 2,21, the interface agent layers 2,21 are respectively provided with quartz sand layers 3,31; It is made by mixing regulators and fillers. The components by weight of each raw material are: 20-40 parts of emulsion, 0-1 part of film-forming aid, 0.05-0.15 part of dispersant, 0.3-1 part of defoamer, anti-mildew 0.5-1 part of thickener, 0.1-0.3 part of thickener, 0-0.5 part of pH regulator, 30-50 parts of filler, 20-30 parts of water; the emulsion is styrene-acrylic emulsion, pure acrylic emulsion, VAE emulsion one or more of them; the coalescent is ethylene glycol or pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com