Novel suspension type thermal insulation soundproof system for wall

A thermal insulation and sound insulation, suspended technology, applied in the direction of thermal insulation, sound insulation, building components, etc., can solve the problems of poor sound insulation effect of the wall, inability to fill the insulation body, and affect the thermal insulation effect, etc., achieve excellent sound absorption and sound insulation effects, and save energy The effect of high consumption and construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

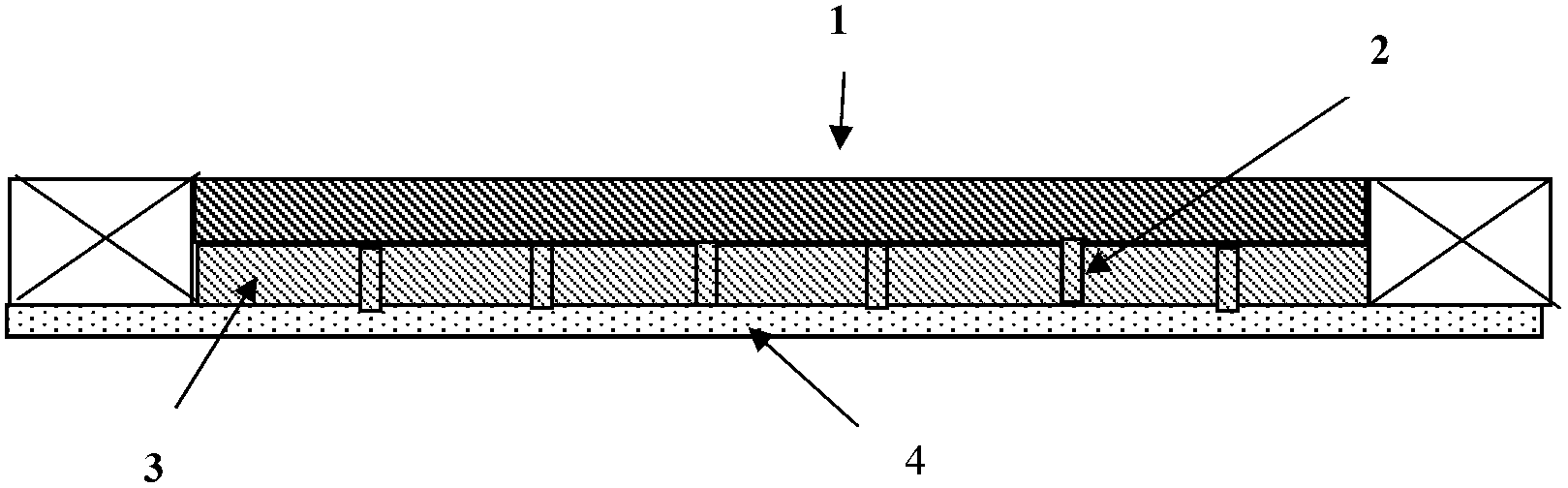

[0033] like figure 1 As shown, a new type of wall suspension thermal insulation system, the system includes a keel 2, a spray-filled thermal insulation body 3 and a decorative board 4, the keel 2 is arranged between the wall 1 and the decorative board 4, and the The spray-filled thermal insulation body 3 is 100% pure glass fiber material (commercially available glass fiber material is used in this embodiment), and the spray-filled thermal insulation body is adopted by the industrial field through professional construction equipment (including the most popular filling spraying machine) Approved by spraying and all fire-resistant fiber spraying. Such as the filling spraying machine produced by the American Spraying Equipment Machinery Factory. The filling spraying machine can fill and spray all fibers up to 4 stories high (about 12 meters), and the speed of the spraying motor Adjustable, the amount of output can be controlled. A complete set of electrical control panel with volt...

Embodiment 2

[0039] see figure 1 Said, a new wall suspension thermal insulation system, the system includes a keel, a spray-filled thermal insulation body and a decorative board, the keel is set between the wall and the decorative board, and the spray-filled thermal insulation body It is filled between the wall, keel and decorative board by spraying.

[0040] The system also includes non-woven fabric, which is connected to the keel through environmental glue or nails, and the spray-filled thermal insulation body is filled in the cavity between the non-woven fabric and the keel by spraying.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com