Fractional condensation vacuum furnace

A technology of graded condensation and vacuum furnace, applied in the direction of furnace, crucible furnace, furnace type, etc., which can solve the problems of product quality reduction and insufficient use of steam heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

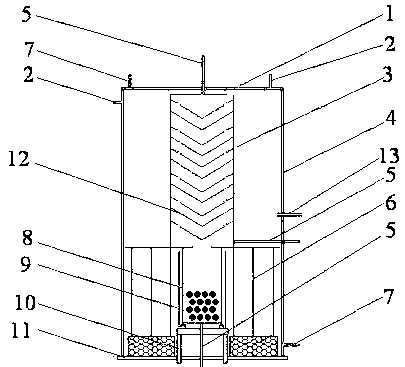

[0007] The equipment is described in further detail below in conjunction with the accompanying drawings:

[0008] This experimental equipment is suitable for extracting and refining more volatile substances in minerals to obtain high-quality products, such as zinc oxide ore. This embodiment includes a water cooling system, an air charging system, a graded condensation vacuum furnace body, a temperature control and detection system, and a vacuum acquisition and detection system. The graded condensation vacuum furnace body (see figure 1 ) including furnace cover 1, cooling water outlet 2, condenser 3, furnace body 4, thermocouple 5, heat shield 6, cooling water inlet 7, graphite crucible 8, graphite heating element 9, water-cooled electrode 10, furnace bottom 11, Condensation pan 12, vacuum pump interface 13 and other parts.

[0009] The steps of extracting the graded and purified products in the graded condensation vacuum furnace are as follows:

[0010] Such as figure 1 As ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com