Fault tolerance type permanent magnetic vernier motor

A vernier motor and permanent magnet technology, which is applied in the fields of electric vehicles, motors, and electrical engineering, can solve the problems that the centralized winding does not have high fault tolerance performance, cannot meet low-speed high-torque operation, and does not have the ability to operate with faults. Fault running capability, elimination of mechanical gearbox, effect of short ends

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

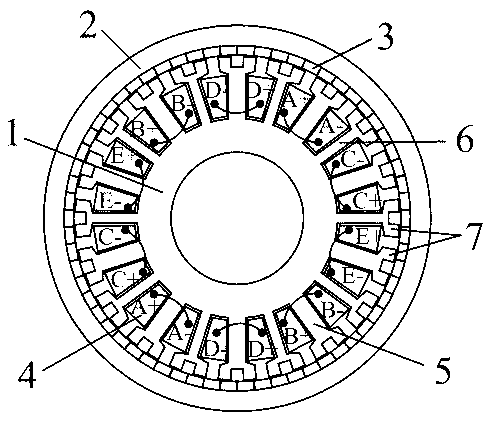

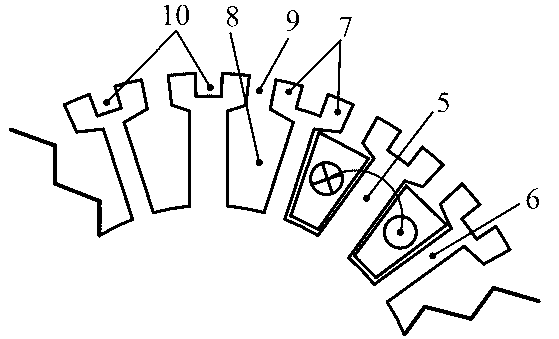

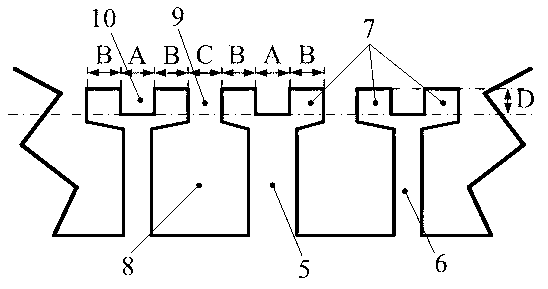

[0023] refer to figure 1 , the present invention includes an inner stator 1 , an outer rotor 2 , a permanent magnet 3 , an armature winding 4 , an armature tooth 5 , a fault-tolerant tooth 6 and a modulation pole 7 . The inner stator 1 and the outer rotor 2 are coaxial, and a permanent magnet 3 , an armature winding 4 , an armature tooth 5 , a fault tolerance tooth 6 and a modulation pole 7 are arranged between the inner stator 1 and the outer rotor 2 . Along the circumferential direction of the inner surface of the outer rotor 2, the permanent magnet 3 is fixed on the inner surface of the outer rotor 2. The material of the permanent magnet 3 is NdFeB, and the magnetization direction is radial. The N pole and S pole of the permanent magnet 3 Alternately.

[0024] 10 armature teeth 5 and 10 fault-tolerant teeth 6 are arranged on the circumference of the inner stator 1. The armature teeth 5 and the fault-tolerant teeth 6 are interlaced with each other. A single-layer concentra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com