Copper-nickel sulphide ore catching agent

A copper-nickel sulfide ore and collector technology, applied in solid separation, flotation, etc., can solve the problems of large consumption, low resource utilization rate, and reduced recovery rate, and achieve improved grade, recovery rate, and mineral floating speed Fast, the effect of drug dosage reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

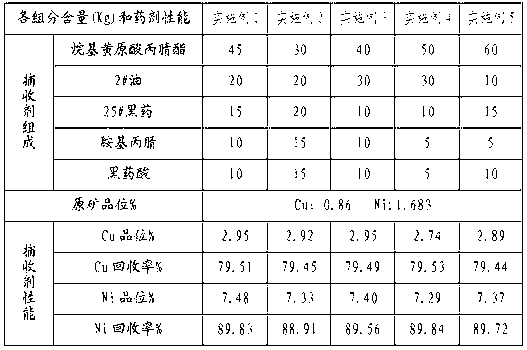

[0016] In the following examples, only the parts by weight of the raw materials are changed, and the method of preparing the collector remains unchanged. In order to more intuitively describe the influence of the changes in the weight of raw materials in different embodiments on the beneficiation index, a single copper ore was selected for the beneficiation test under the same conditions, and the grade and recovery rate of the copper and nickel crude concentrates were listed respectively. The change in the beneficiation index of nickel coarse concentrate reflects the performance of the collector synthesized by different raw material weight parts. The high grades of the copper and nickel crude concentrates indicate that the collectors have strong selection performance; the high recovery rate of the copper and nickel crude concentrates indicates that the collectors have strong collecting performance.

[0017] The specific numerical values of Example 1 to Example 5 are shown in Ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com