Device and method for desanding and disinfecting pretreatment of municipal sludge

An urban sludge and pretreatment technology, applied in sludge treatment, water/sludge/sewage treatment, sludge treatment by temperature control, etc., can solve the problems of high sand content and wear and tear of treatment facilities, and achieve high efficiency Hydrolysis conversion, realize continuous feeding and discharging operation, realize the effect of equipment and automatic operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further illustrated and described below in conjunction with the accompanying drawings and specific embodiments.

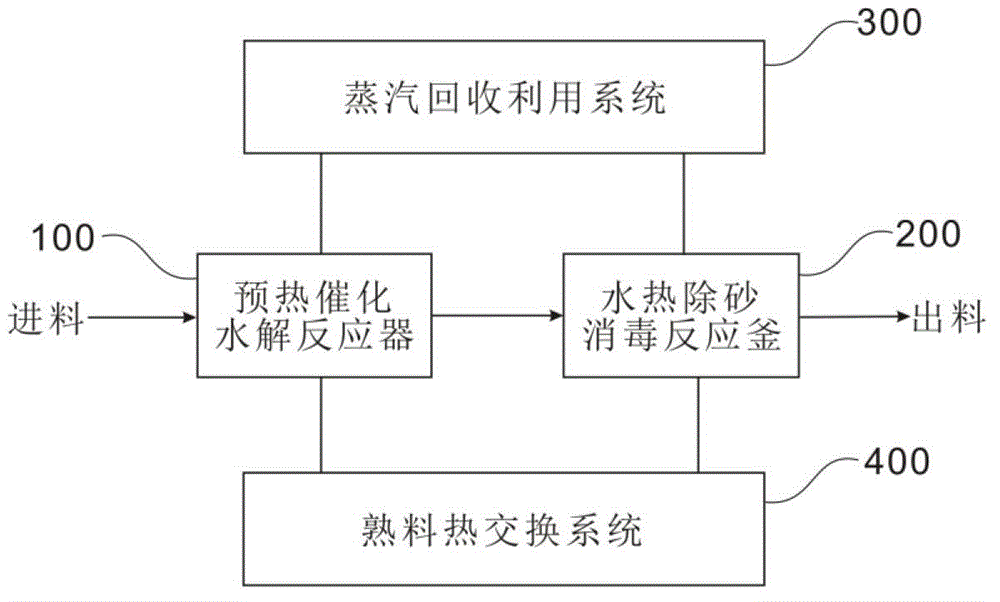

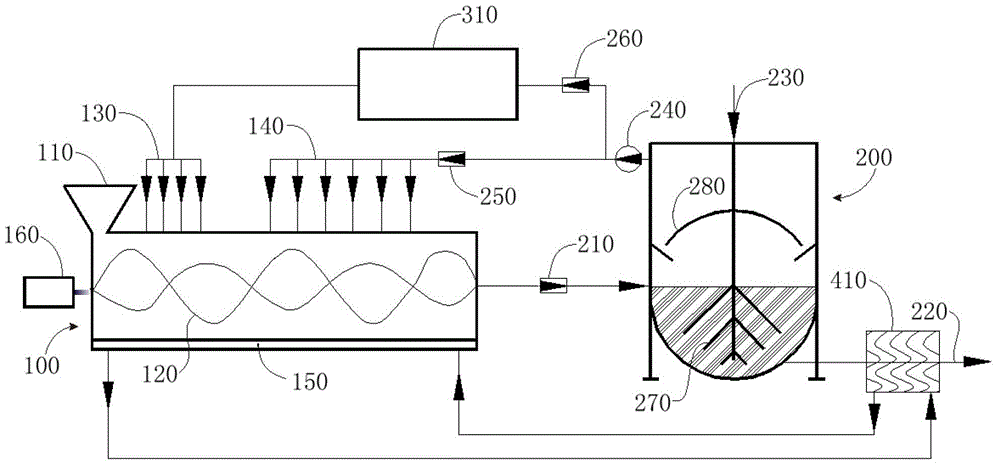

[0021] In the embodiment of the present invention, such as figure 1 As shown, the device for pretreatment of municipal sludge desanding and disinfection of the present invention includes a preheating catalytic hydrolysis reactor 100, a hydrothermal desanding and disinfection reaction kettle 200, a steam recycling system 300 and a clinker heat exchange system 400, wherein the The preheating catalytic hydrolysis reactor 100 is used to preheat and pretreat the materials by catalytic hydrolysis, and the hydrothermal desanding and disinfection reactor 200 is used to react the pretreated materials under high temperature and high pressure conditions to achieve The sand in the material is separated from the organic matter of the sludge and the disinfection treatment of the sludge is realized. The steam recovery and utilization system 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com